Shell and manufacture method thereof

A manufacturing method and shell technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as poor corrosion resistance, peeling, and different colors, and achieve improved corrosion resistance and good decoration Appearance, avoid the effect of discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

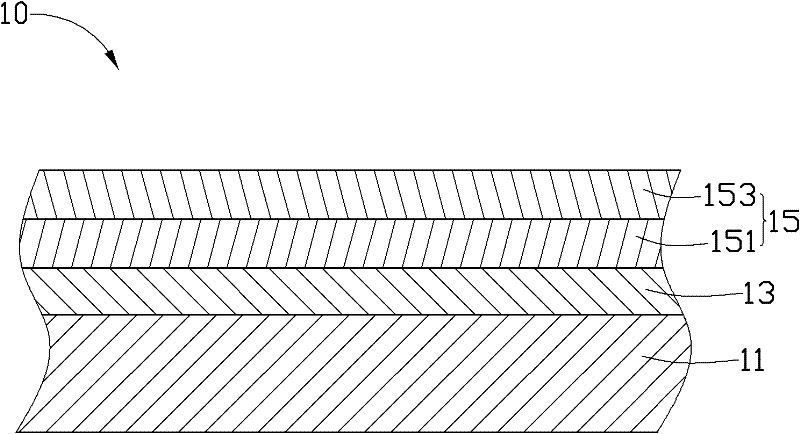

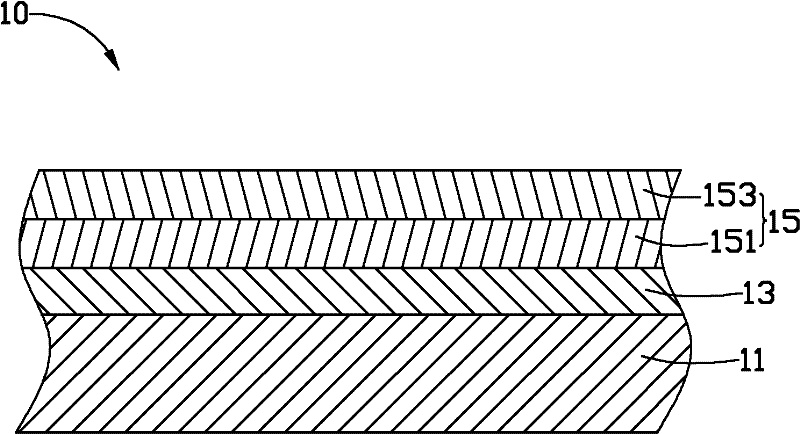

[0021] see figure 1 , the housing 10 of a preferred embodiment of the present invention comprises a magnesium or magnesium alloy substrate 11, magnesium silicide (Mg silicide) formed on the magnesium or magnesium alloy substrate 11 in sequence 2 Si) layer 13 and color layer 15. The casing 10 can be a casing of a 3C electronic product, and can also be a frame of glasses, a construction piece, and a part of a vehicle such as an automobile.

[0022] The Mg 2 The thickness of the Si layer 13 is 300-1000 nm.

[0023] The color layer 15 is an electrical insulating layer with anti-corrosion properties. The color layer consists of sequentially formed Mg 2 Titanium dioxide (TiO 2 ) layer 151 and silicon dioxide (SiO 2 ) layer 153. The TiO 2 The thickness of layer 151 is 50-150nm, the SiO 2 The thickness of layer 153 is 50-150 nm.

[0024] The Mg 2 Both the Si layer 13 and the color layer 15 can be deposited and formed by magnetron sputtering. It can be understood that the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com