Aluminum product and preparation method thereof

A technology for aluminum products and aluminum substrates, applied in the field of aluminum products and their preparation, which can solve the problems of falling off, inability to effectively prevent electrochemical corrosion of aluminum or aluminum alloy substrates, and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

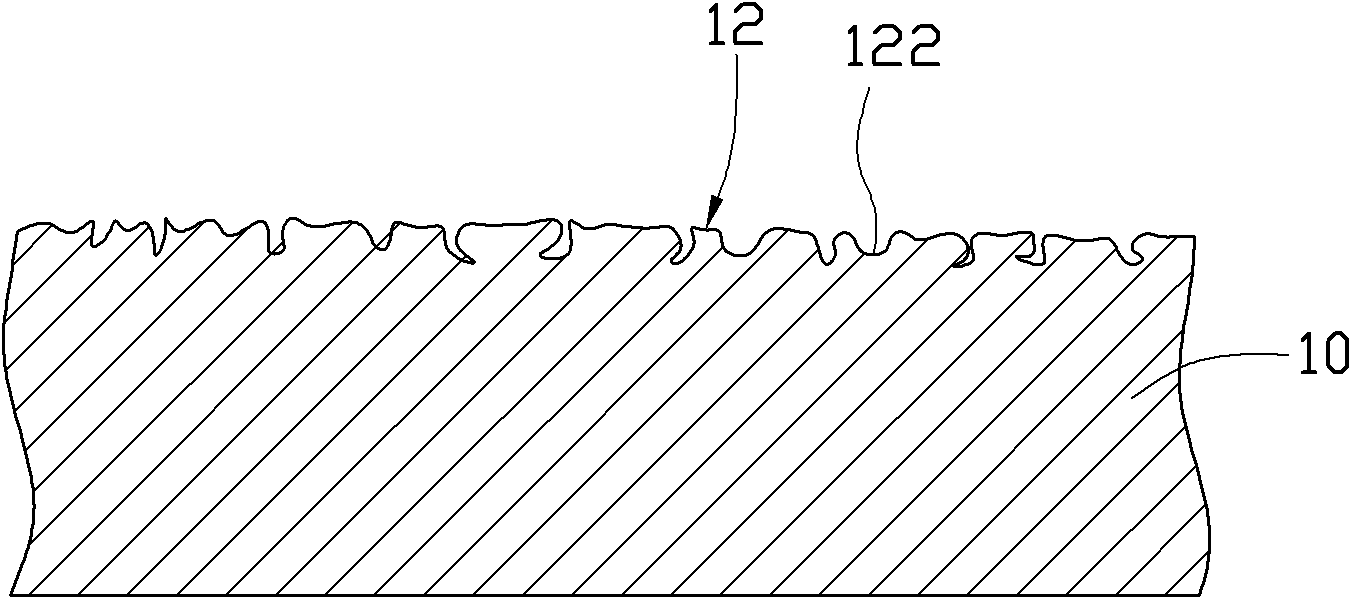

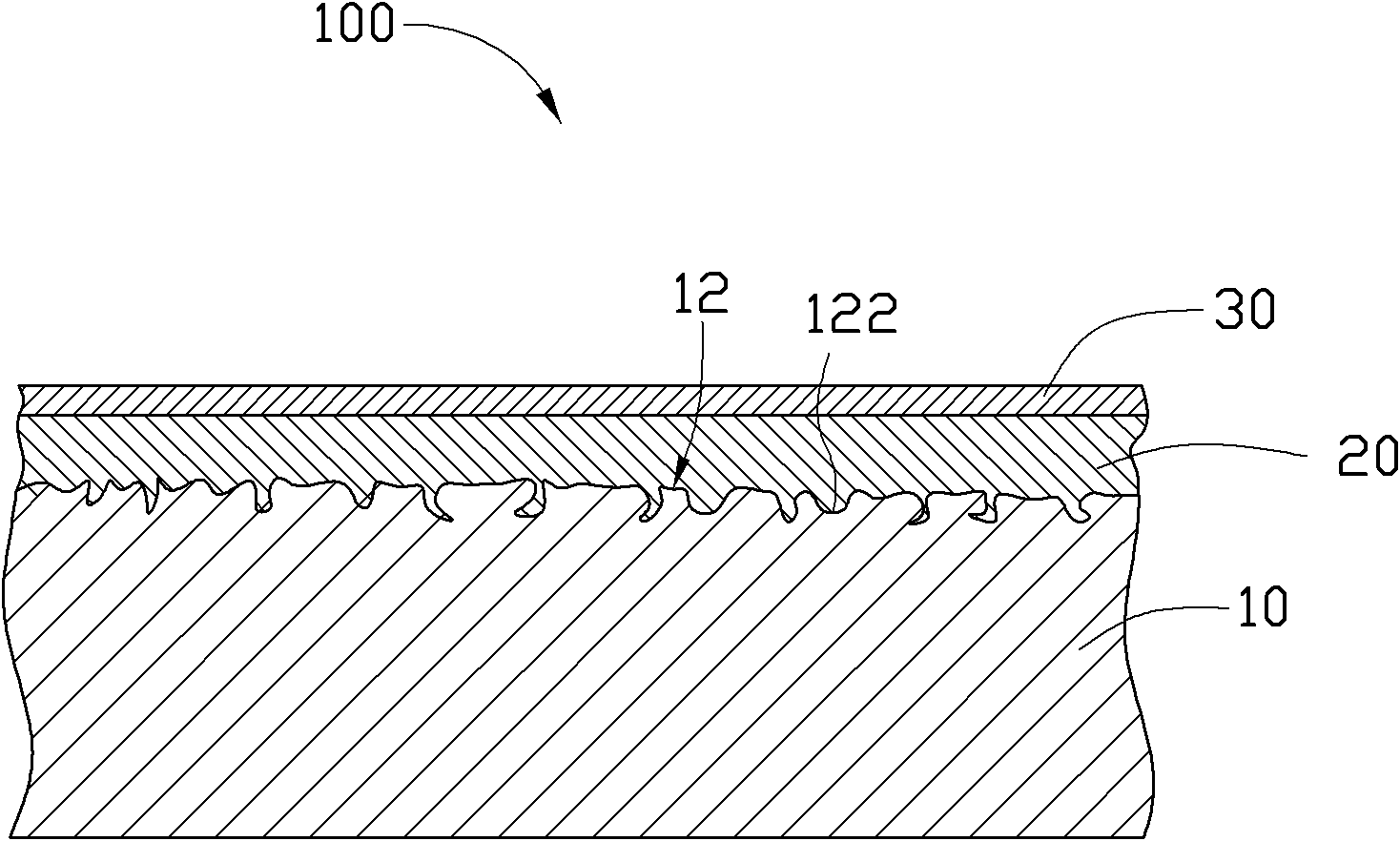

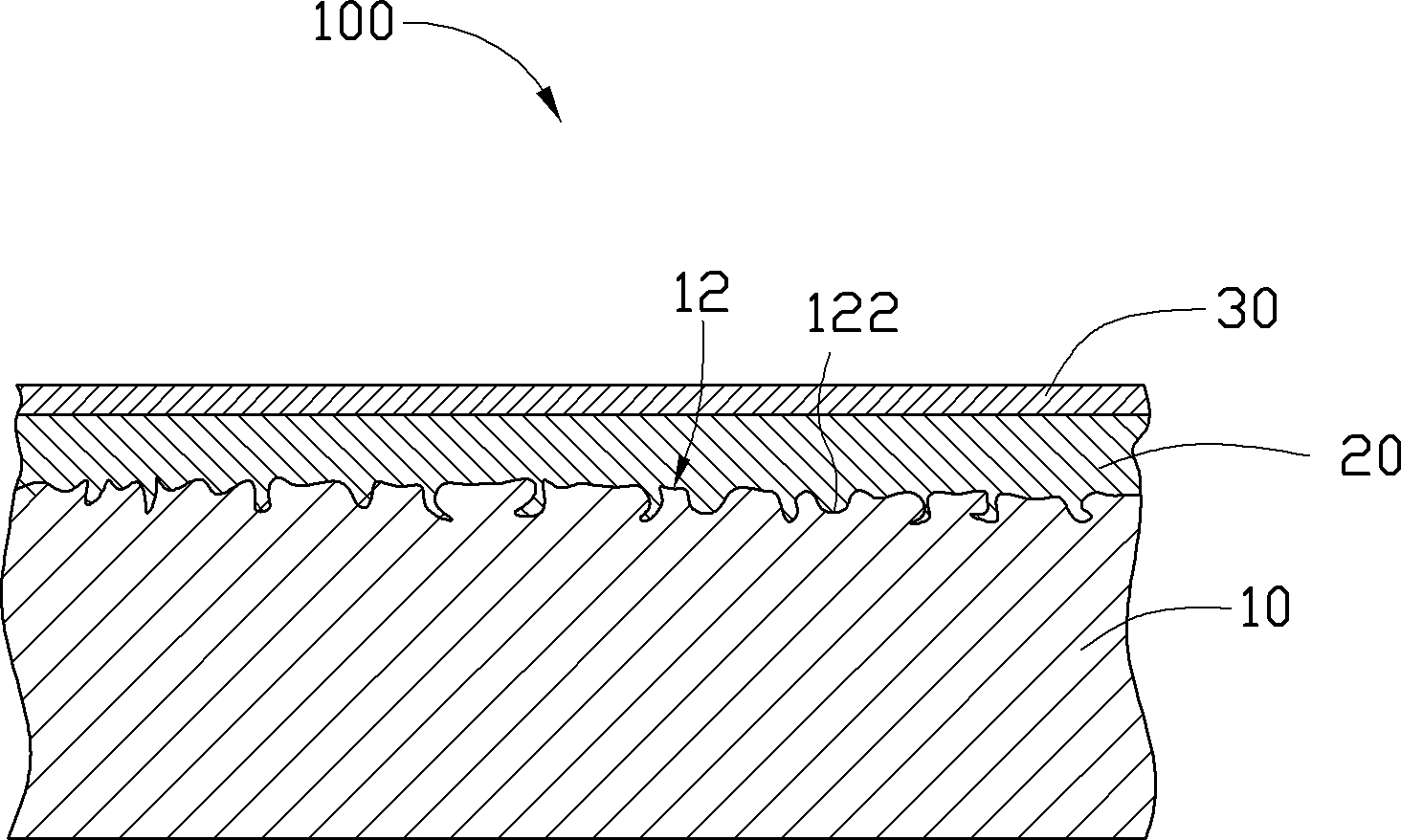

[0022] see figure 1 and figure 2 ( figure 2 The mark is wrong, please modify), the aluminum product 100 of the preferred embodiment of the present invention includes an aluminum substrate 10 and an anodized film 20 and a color layer 30 formed on the aluminum substrate 10 in sequence. The aluminum product 100 can be a casing of a 3C electronic product, and can also be a frame of glasses, a construction piece, and a part of a vehicle such as an automobile.

[0023] The aluminum base 10 is made of aluminum or aluminum alloy. The aluminum substrate 10 is electrochemically etched to form a porous surface 12 , and a plurality of nanopores 122 are evenly distributed on the porous surface 12 . The diameter of the nanopore 122 is 8-20 nm, preferably 10-15 nm. The depth of the nanohole 122 is much smaller than the thickness of the color layer 30 .

[0024] The anodized film 20 is formed on the porous surface 12 of the aluminum substrate 10 . The anodized film 20 is obtained by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com