Anti-corrosion method of cupronickel B30

An anti-corrosion and cupronickel technology, applied in the coating process of metal materials, etc., can solve the problems of complex operation, long processing time, expensive metal hydrophobic surface equipment and medicines, etc., and achieve simple process, short processing time and broad practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

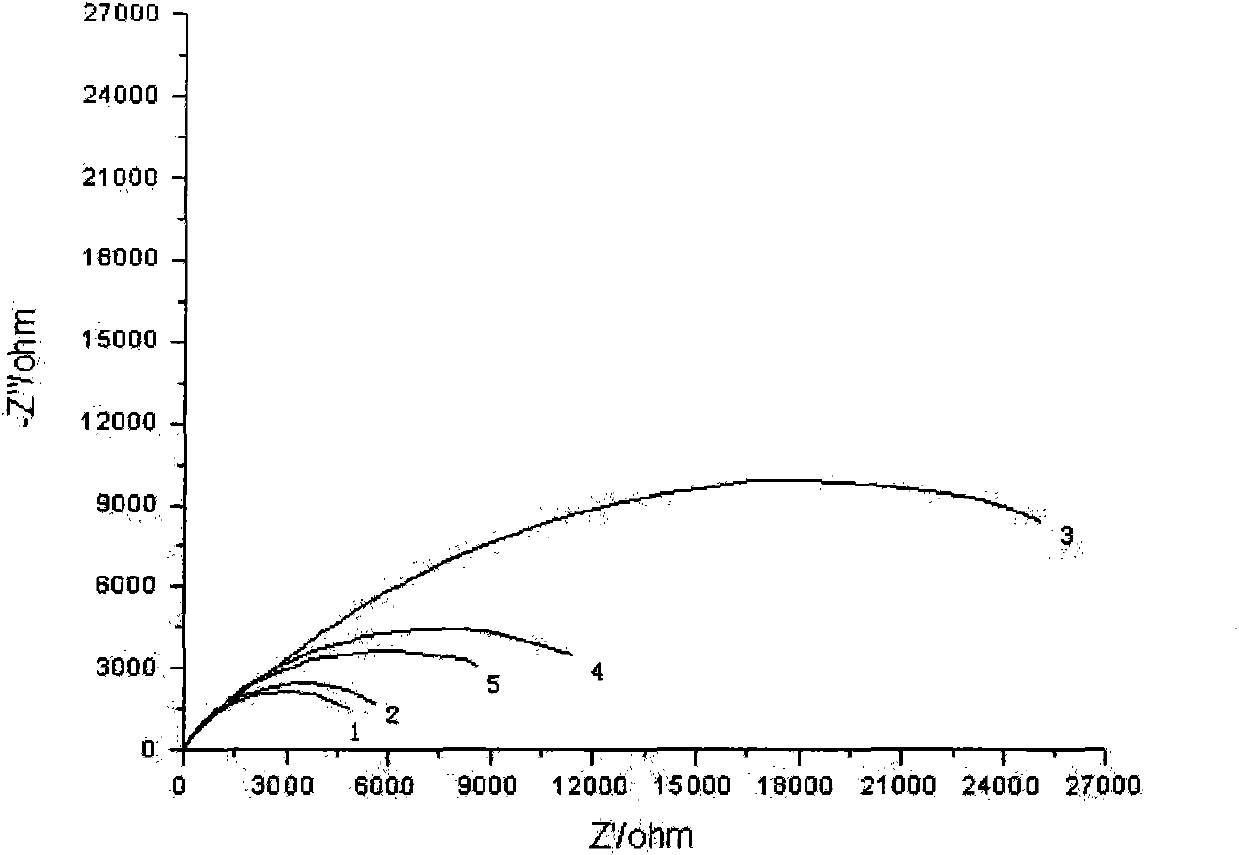

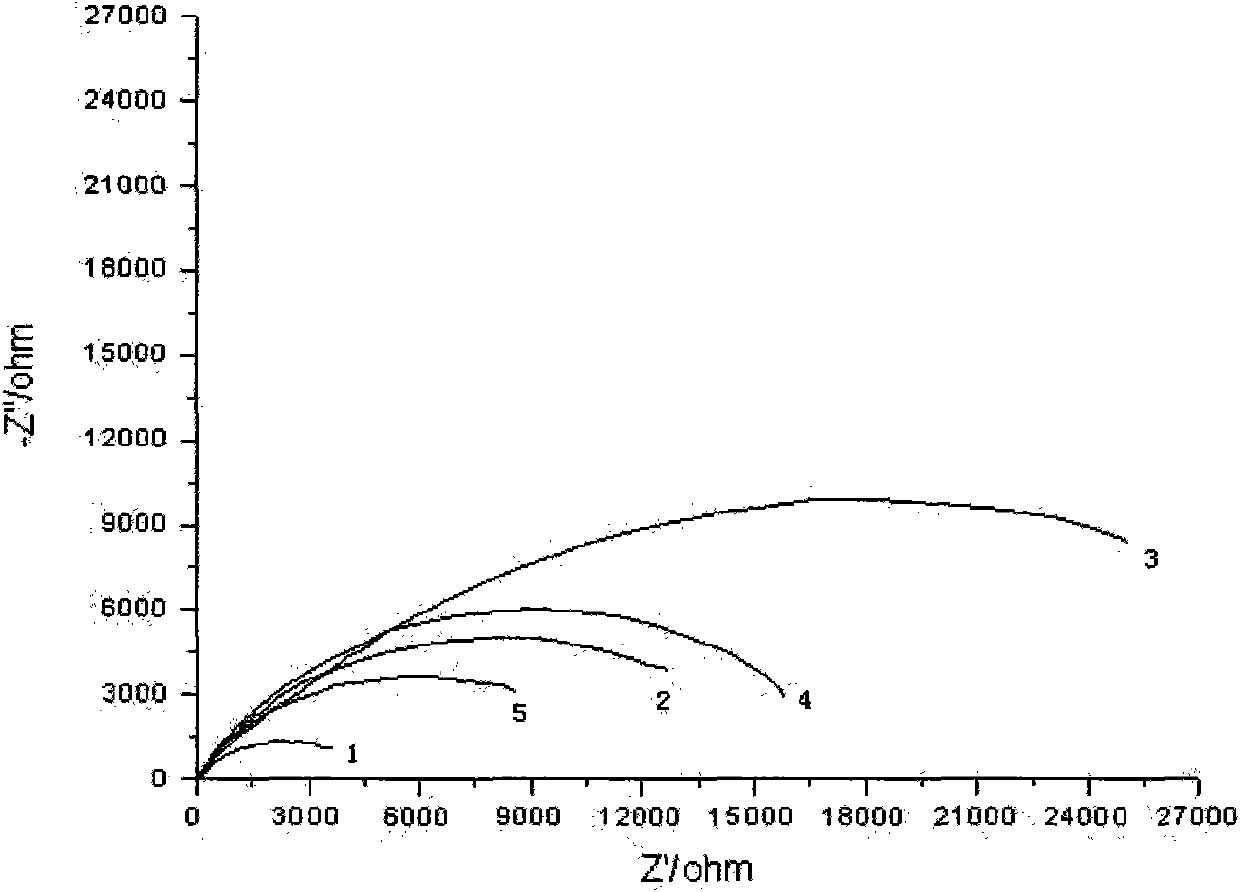

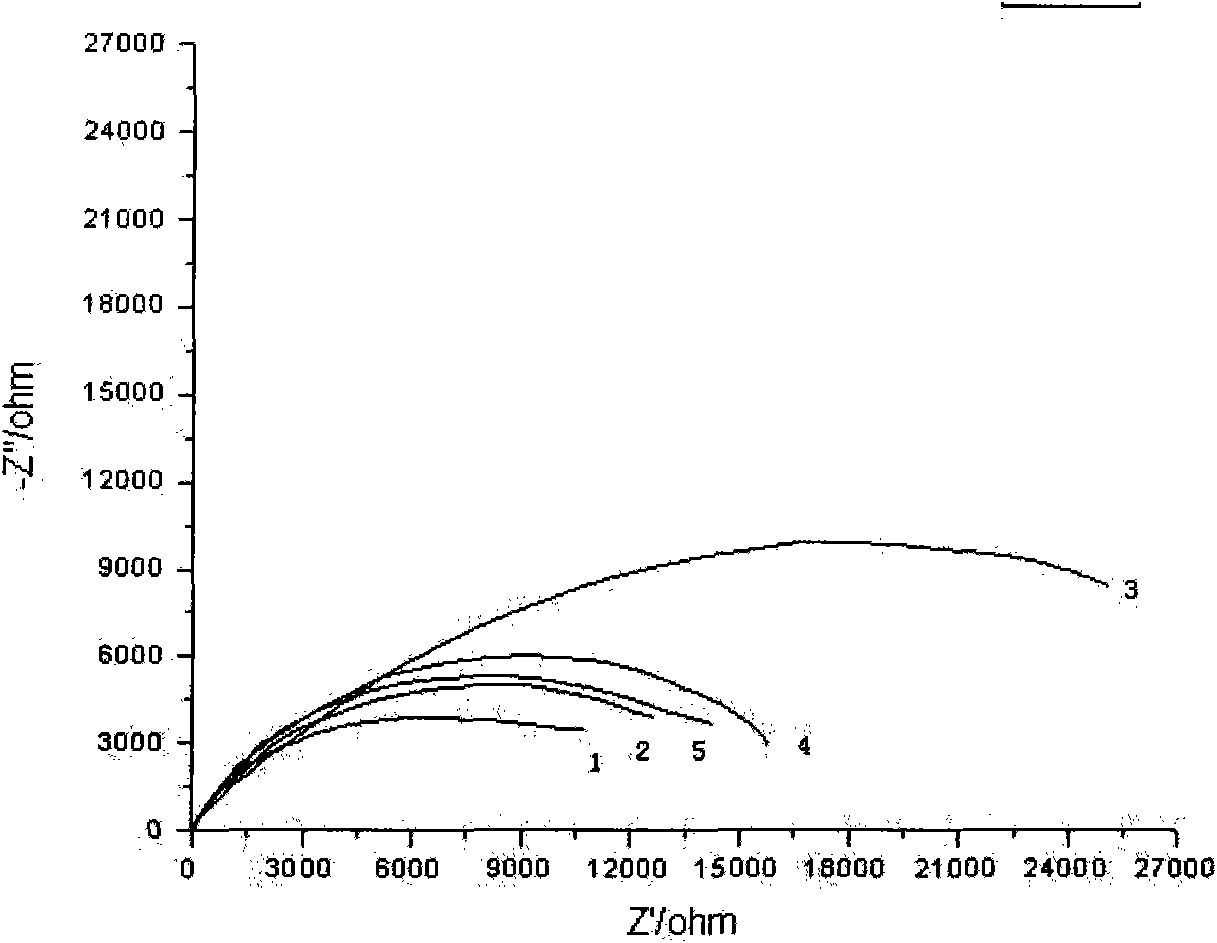

[0023] The present invention is further elaborated below by embodiment and accompanying drawing: a kind of anticorrosion method of cupronickel B30 comprises the following steps:

[0024] (1) The configuration concentration is 3 to 10% H 2 o 2 water solution and 0.05-2% stearic acid ethanol solution, the cleaned and treated white copper B30 is immersed in 3-10% H2O2 aqueous solution for 15-60 minutes and 0.05-2% stearic acid ethanol solution for 10-60 minutes, on the copper base Obtain a hydrophobic and corrosion-resistant surface on the material;

[0025] (2) The white copper B30 treated by the above steps and Na with a concentration of 0.02-0.2g / L 2 WO 4 Corrosion inhibitor compound use.

[0026] A more optimized anti-corrosion method for cupronickel B30, comprising the following steps:

[0027] (1) Clean the cleaned copper-nickel B30 at a concentration of 5% H 2 o 2 Soak in the solution for 30 minutes, and then soak in stearic acid ethanol solution with a concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com