Method for preparing composite coating by surface differential arc oxidation/chemical conversion of Mg-Li alloy

A technology of micro-arc oxidation and chemical conversion, applied in anodizing and other directions, can solve the problems of patents and literature reports on the surface of magnesium-lithium alloy surface micro-arc oxidation and micro-arc oxidation/chemical conversion composite coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] (1) Pretreatment

[0030] In order to make the micro-arc oxide film have a good bonding force with the substrate, the pretreatment of the Mg-Li alloy surface is an important factor. The requirement of the surface pretreatment of the Mg-Li alloy is to remove the oxide on the surface of the Mg-Li alloy to obtain Clean surface, therefore, the Mg-Li alloy matrix must be surface pretreated before the reaction.

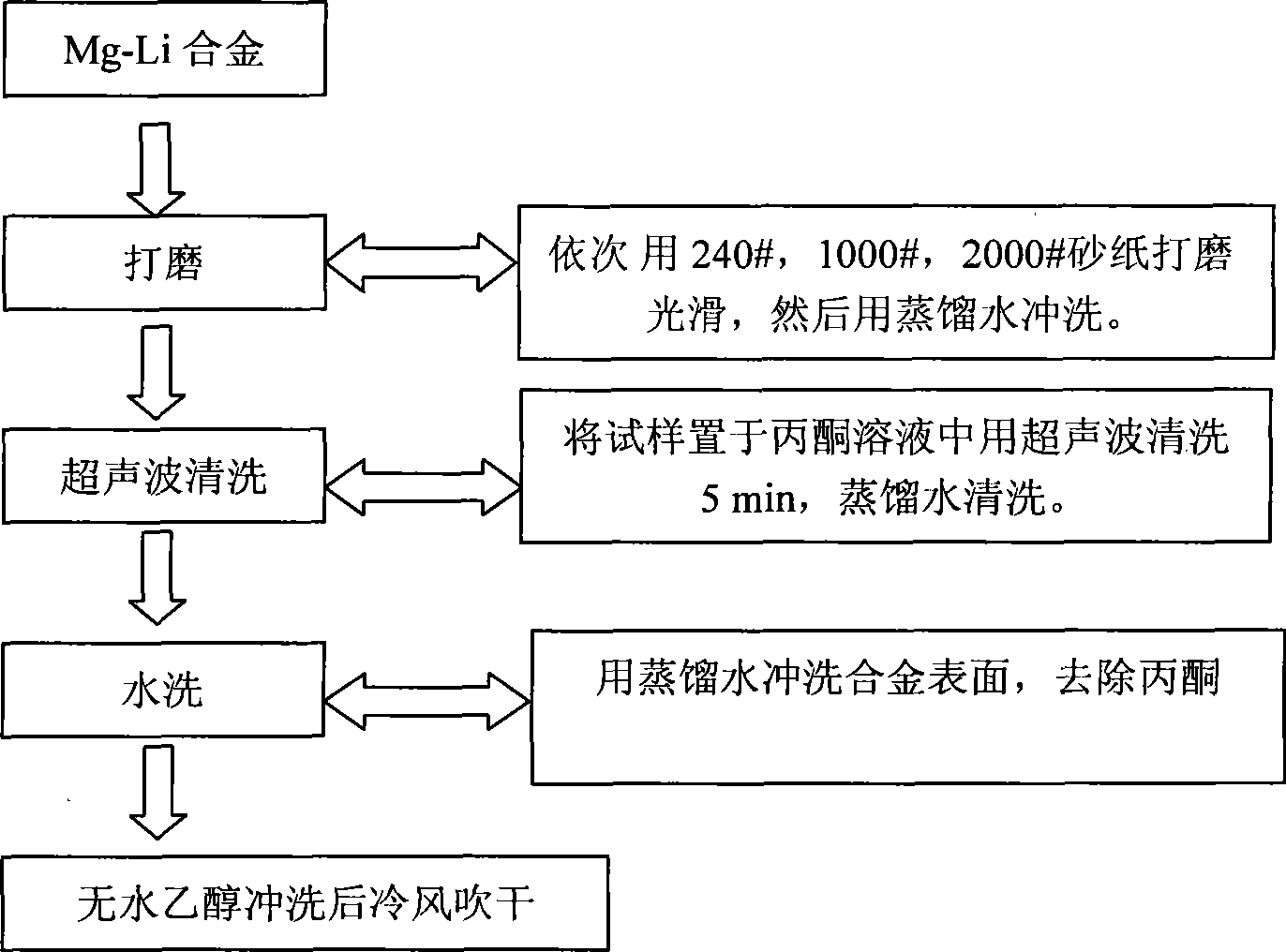

[0031] Combine figure 1 The specific process of pretreatment is:

[0032] Use 240#, 1000#, 2000# sandpaper to polish the Mg-Li alloy in sequence, and then rinse with distilled water; place the polished Mg-Li alloy in an acetone solution, ultrasonically clean for 5 minutes, and rinse with distilled water; finally, rinse and rinse with ethanol. Blow dry.

[0033] (2) Micro arc oxidation

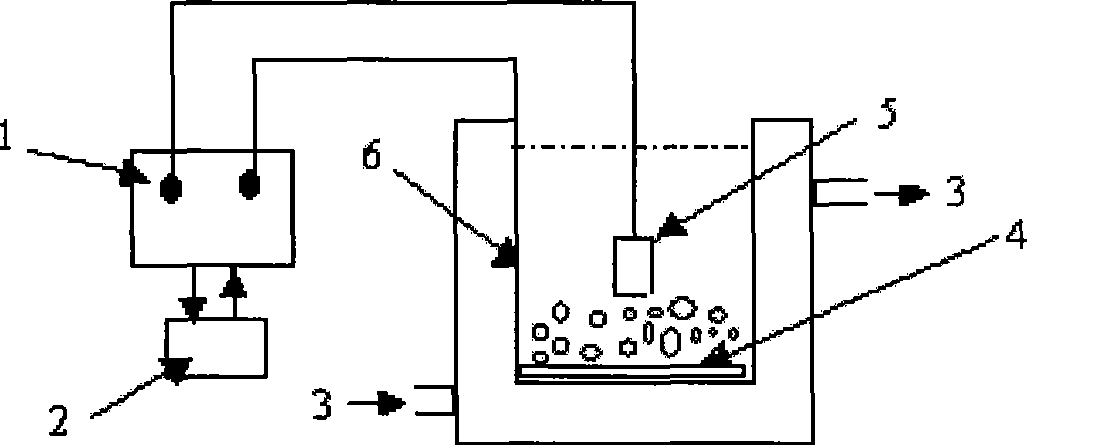

[0034] Place the pre-treated Mg-Li alloy in figure 2 In the electrolyte of the micro-arc oxidation system shown, the composition of the system includes a DC / DC pulse / AC pulse multiplexi...

specific Embodiment approach 2

[0037] (1) Pretreatment of Mg-Li alloy surface

[0038] Carry out the pretreatment of the Mg-Li alloy surface, and immediately carry out the plasma electrolytic oxidation reaction after the pretreatment to avoid oxidation of the treated Mg-Li alloy in contact with air for too long.

[0039] (2) Micro arc oxidation

[0040] The pre-treated Mg-Li alloy is placed in an alkaline silicate electrolyte system; the alloy is subjected to micro-arc oxidation treatment by DC pulse electric output; constant current density: 5A / dm 2 , The output voltage changes continuously during the oxidation process. In this mode, the micro-arc oxidation time is 4 minutes, and the output voltage in the micro-arc oxidation stage is 400V-450V; the Mg-Li alloy sample after the micro-arc oxidation is washed with water and dried with cold air.

[0041] (3) Chemical transformation

[0042] Put the Mg-Li alloy treated by micro-arc oxidation completely into the chemical conversion solution; the reaction temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com