Method for preparing graphene oxide and micro-arc oxidized ceramic composite coating on surface of magnesium alloy

A ceramic composite film and micro-arc oxidation technology, which is applied in anodic oxidation, metal material coating process, coating, etc., can solve the problems of poor corrosion resistance, achieve the effects of improved corrosion resistance, stable structure, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

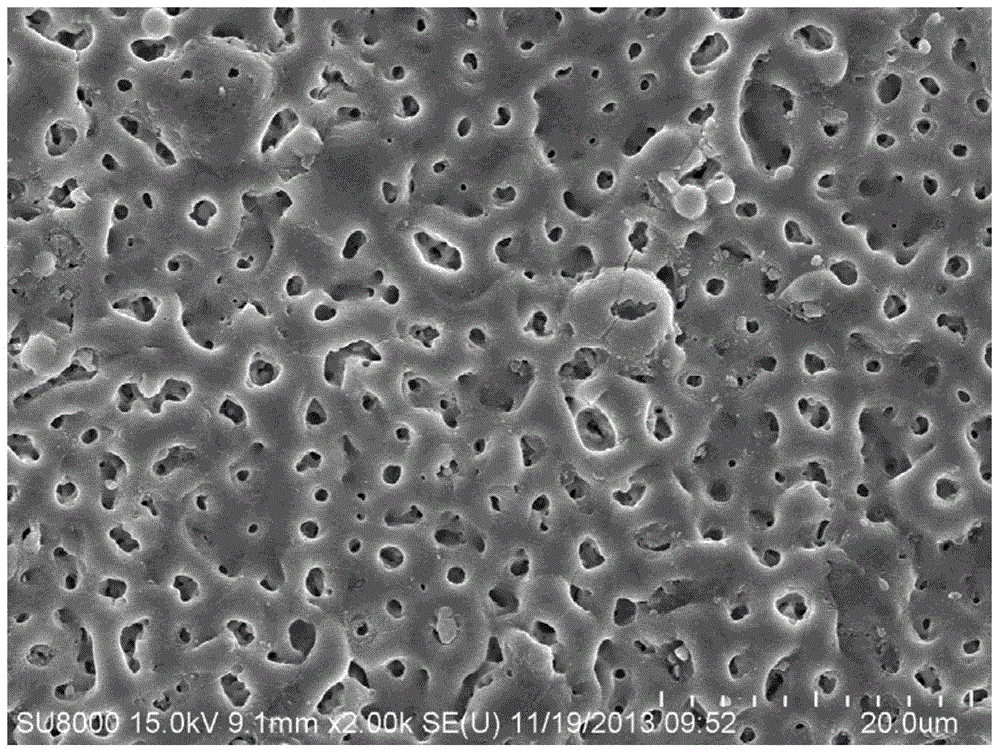

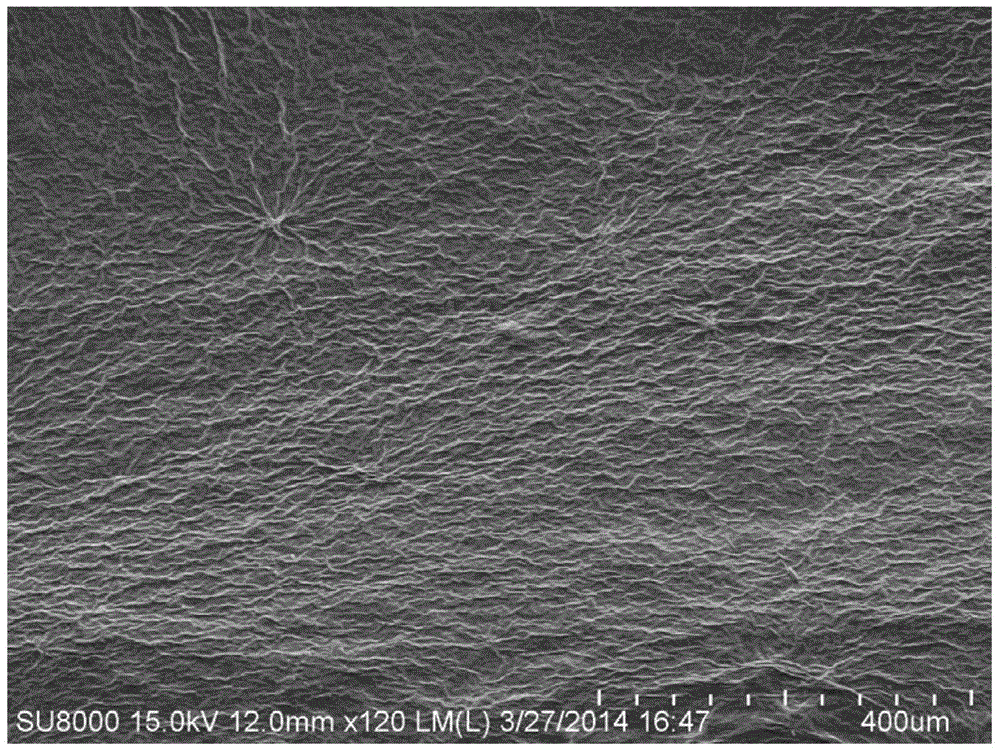

[0033] Specific embodiment one: this embodiment is a method for preparing graphene oxide and micro-arc oxidation ceramic composite film on the surface of magnesium alloy, which is completed in the following steps:

[0034] A method for preparing graphene oxide and micro-arc oxidation ceramic composite film layer on the surface of magnesium alloy is completed according to the following steps:

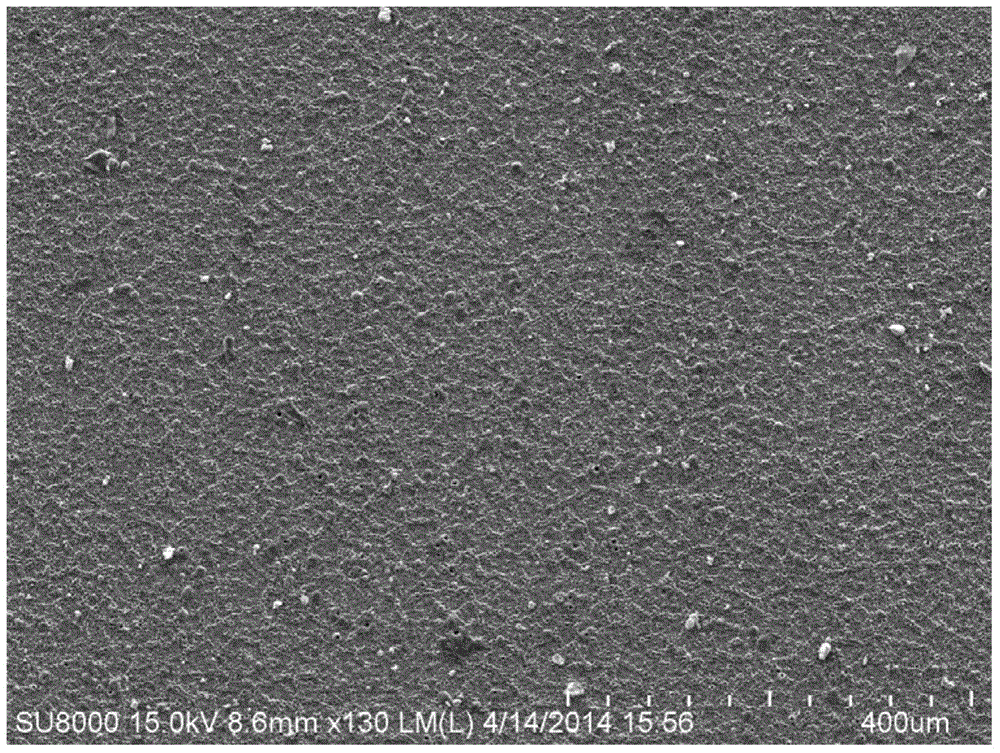

[0035] 1. Magnesium alloy pretreatment: Use 180#SiC sandpaper, 1000#SiC sandpaper and 2000#SiC sandpaper to polish the magnesium alloy in sequence to obtain a bright magnesium alloy;

[0036] 2. Ultrasonic treatment: immerse the magnesium alloy with a bright surface in acetone, and ultrasonically treat it for 3 minutes to 10 minutes at an ultrasonic power of 200W~300W to obtain the magnesium alloy after ultrasonic treatment;

[0037] 3. Degreasing: First, immerse the ultrasonically treated magnesium alloy in a NaOH solution with a temperature of 60°C-75°C and a concentration of 40g / L-50g...

specific Embodiment approach 2

[0052] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the magnesium alloy described in step 1 is a ZK60 magnesium alloy. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0053] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the graphene oxide film layer in the magnesium alloy covered with graphene oxide and micro-arc oxidation ceramic composite film layer described in step six The thickness is 4 μm to 6 μm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com