Chromium-free passivator as well as preparation method and application thereof

A chromium-free passivation agent and scheme technology, applied in the coating process of metal materials, etc., can solve the problems of phosphorus pollution, increased silicon content, unstable passivation solution, etc., and achieve less side reactions, improved passivation performance, and corrosion resistance. The effect of current reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] First, the electrolytic manganese is prepared in a diaphragm tank by electrolysis: stainless steel is used as the cathode plate, and a lead-silver alloy plate is used as the anode plate. Electrolysis conditions: ammonium sulfate 120g / L, manganese sulfate 36.91g / L, selenium dioxide 0.05g / L catholyte, catholyte pH is about 6.8~7.0, current density is 350A / m 2 , the electrolysis temperature was 38°C, and the electrolysis time was 1.5h. The prepared electrolytic manganese product was used for subsequent passivation experiments and performance evaluation of the passivation layer.

[0049] The percentage by weight of each component of the passivator is: stearic acid 16.4%, stearic acid diethanolamide 81.9%, ascorbic acid 1.7%. Stearic acid, stearic acid diethanolamide and water are heated and stirred at 80° C. to dissolve first, and then ascorbic acid is added to stir and dissolve to obtain a chromium-free passivation solution (concentration: 3%) for surface treatment of elec...

Embodiment 2

[0079] The preparation of electrolytic manganese metal is the same as in Example 1.

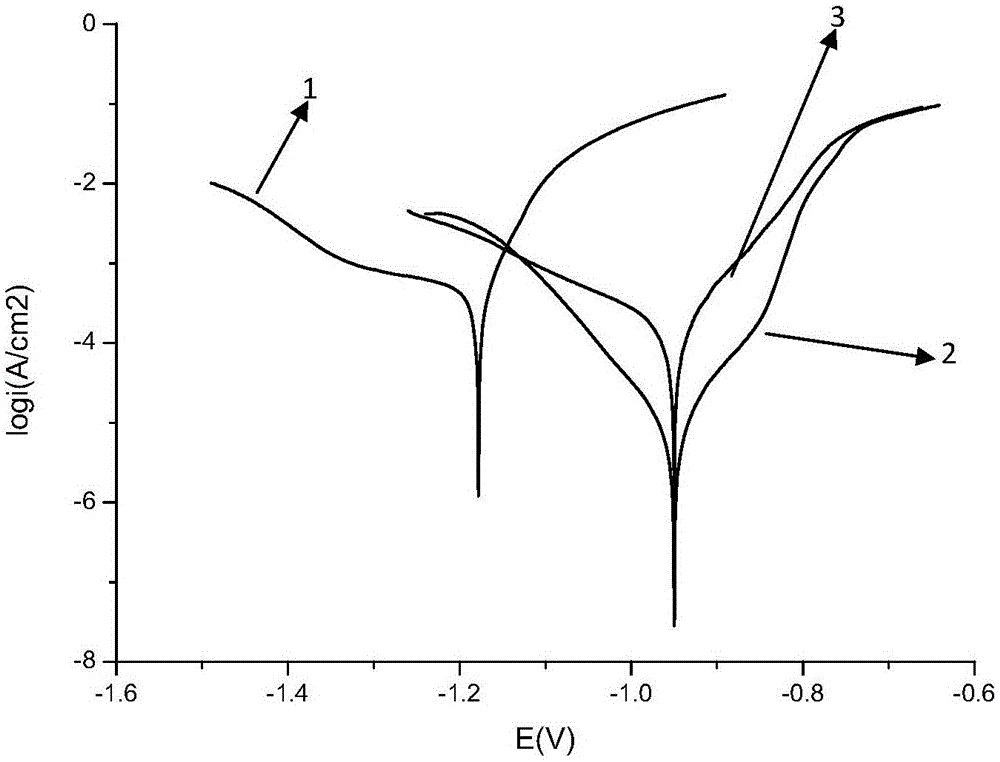

[0080] The percentage by weight of each component of the passivator is: 16% of lauric acid, 82.4% of oleic acid diethanolamide, and 1.6% of ethylenediaminetetraacetic acid. First, lauric acid, oleic acid diethanolamide and water were heated and stirred at 80° C. to dissolve, and then ethylenediaminetetraacetic acid was added to obtain a chromium-free passivation solution (concentration: 3%) for surface treatment of electrolytic manganese metal. The passivation agent was used to conduct passivation and electrochemical performance tests on electrolytic manganese, and the polarization curve results are shown in Table 5.

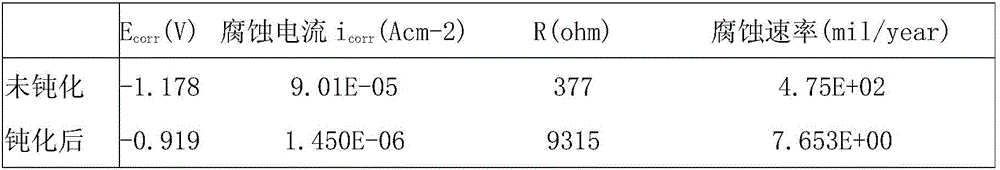

[0081] Table 5 lauric acid and other passivation polarization curve results

[0082] E. corr (V) i corr (Acm-2) R(ohm) Corrosion rate (mil / year) Not passivated -1.178 9.01E-05 377 4.75E+02 After passivation -0.950 7.475E-07 20116 3.946E+00...

Embodiment 3

[0085] The preparation of electrolytic manganese metal is the same as in Example 1.

[0086] The percentage by weight of each component of the passivator is: 16% of palmitic acid, 82.4% of stearic acid diethanolamide, and 1.6% of triethanolamine. Palmitic acid, stearic acid diethanolamide and water were first heated and stirred at 80° C. to dissolve, and then triethanolamine was added to obtain a chromium-free passivation solution (concentration: 3%) for surface treatment of electrolytic manganese metal. The passivation solution was used to conduct passivation and electrochemical performance tests on electrolytic manganese, and the polarization curve results are shown in Table 6.

[0087] Table 6 Passivation polarization curve results

[0088] E. corr (V) i corr (Acm-2) R(ohm) Corrosion rate (mil / year) Elemental manganese -1.178 9.01E-05 377 4.75E+02 After passivation -0.95 5.628E-06 3218 2.971E+01

[0089] In the potassium permangan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com