Preparation process of cerium-doped silicon corrosion-resisting membrane on surface of aluminium alloy

A technology of aluminum alloy surface and preparation process, applied in the direction of metal material coating process, etc., can solve the problems of complex process, high temperature, poor compactness of corrosion-resistant film, etc., and achieve simple process, shortened film-forming time, and reduced corrosion current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

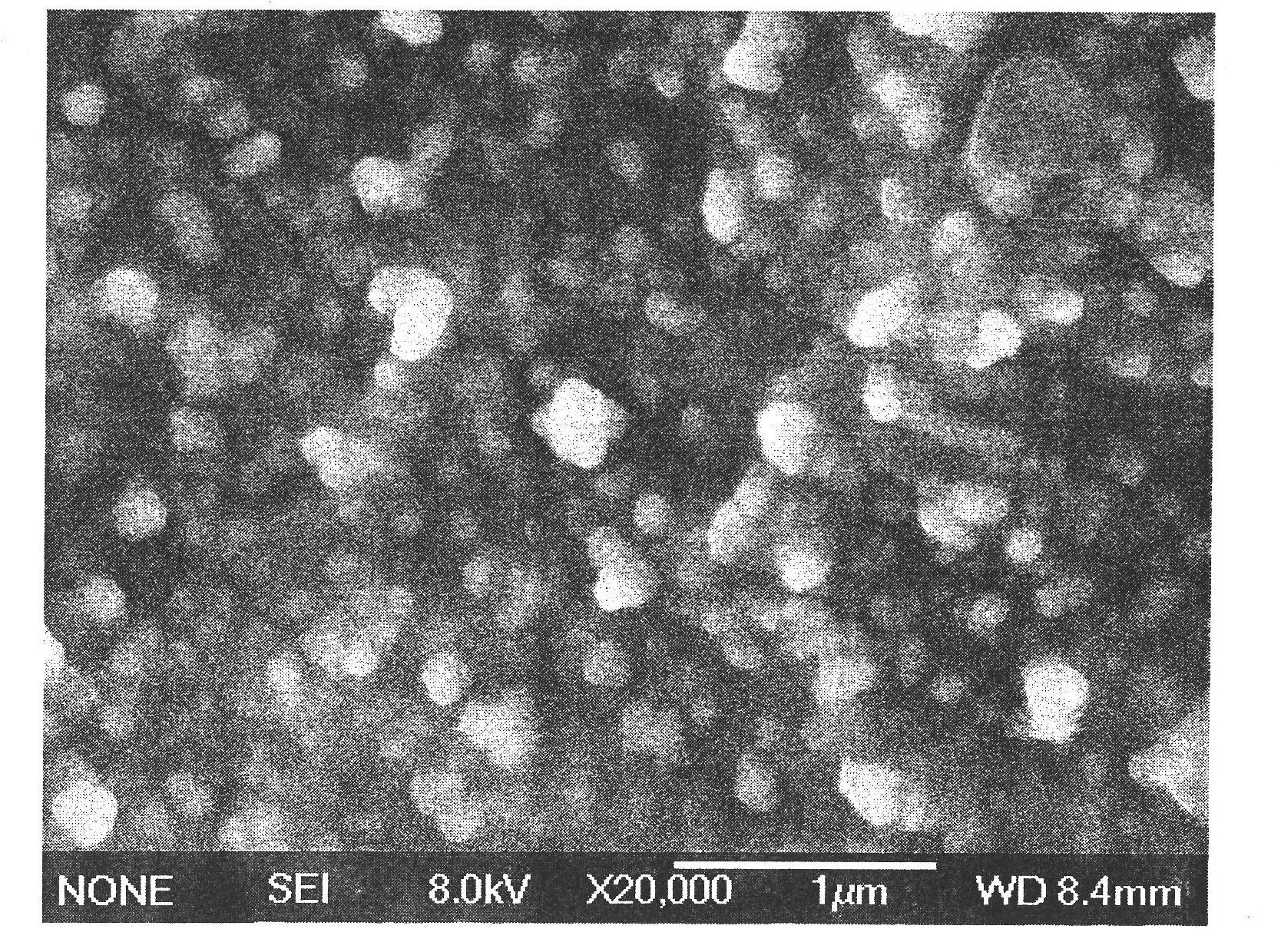

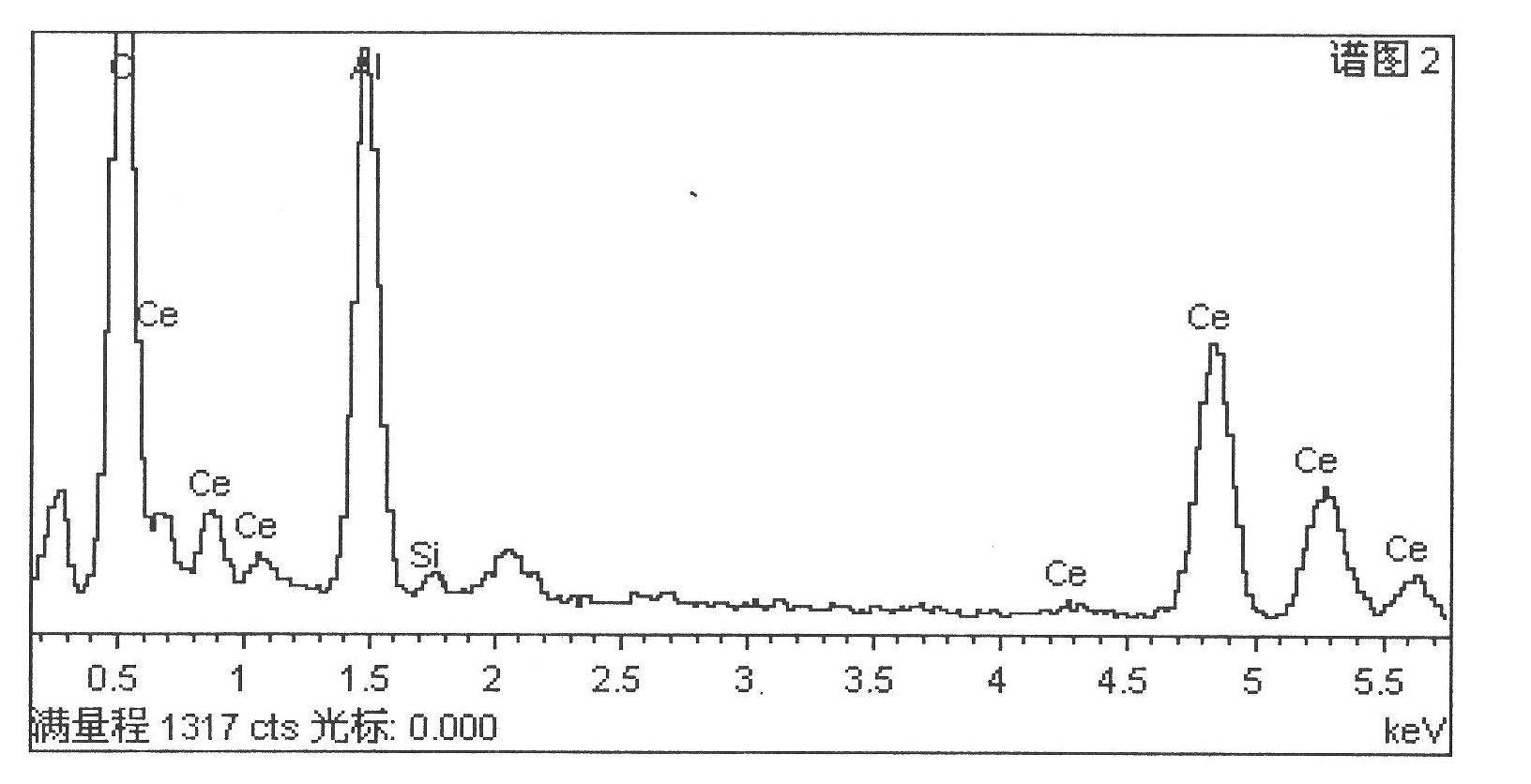

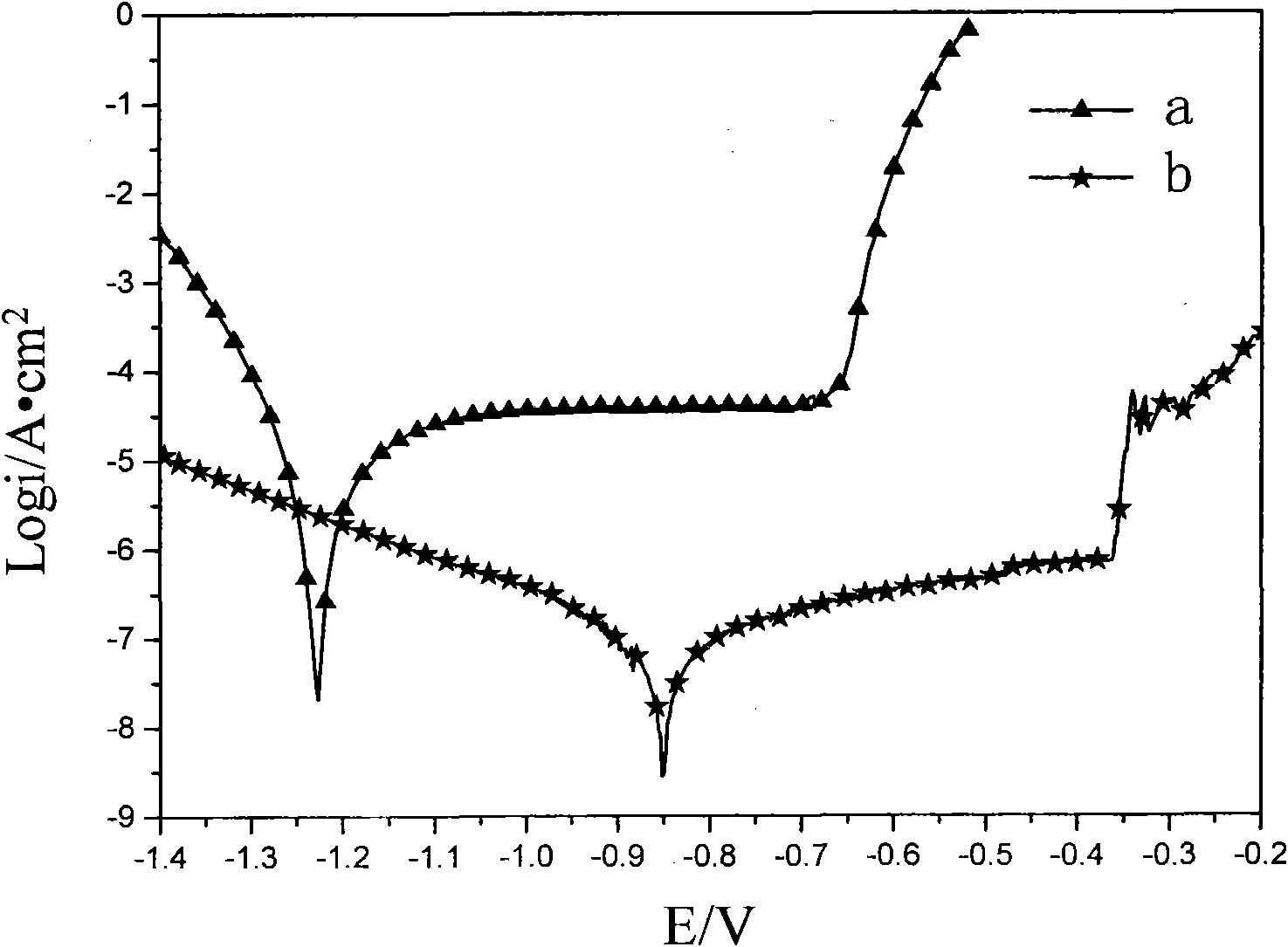

[0020] Formation of silicon-doped cerium corrosion-resistant film on the surface of 1060 aluminum alloy

[0021] Firstly, the surface of 1060 aluminum alloy is pretreated. The steps are: polish the aluminum alloy with water-resistant sandpaper until it is bright, and rinse it with deionized water; wash it in acetone solution at room temperature for 4 minutes, and rinse it with deionized water after taking it out; 40℃ Soak it in an alkaline aqueous solution for 3 minutes, take it out and rinse it with deionized water. The alkaline aqueous solution contains 30 g / L of sodium hydroxide and 25 g / L of anhydrous sodium carbonate.

[0022] Then immerse the pretreated 1060 aluminum alloy in the cerium salt conversion liquid, and react at room temperature for 7 minutes. The configuration process of the cerium salt conversion liquid is as follows: 40g cerous chloride hydrate, 160g sodium perchlorate, 0.5g sodium benzoate and 0.5g benzotriazole are dissolved in 900g deionized water at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com