Nanocrystalline ZrC/Zr composite coating of metal bipolar plate of proton exchange membrane fuel cell and preparation method thereof

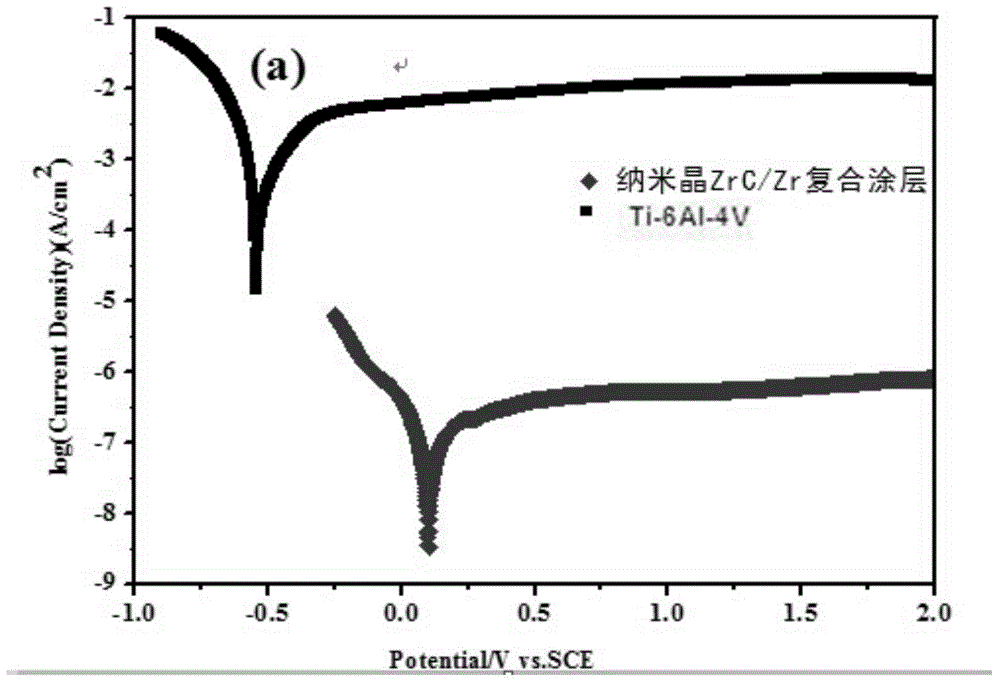

A technology of titanium alloy bipolar plate and proton exchange membrane, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problem of waste liquid polluting the environment, affecting the durability and safety of coated bipolar plates, Reduce the corrosion resistance of the silver-plated stainless steel layer and achieve the effects of simple process, low coating preparation cost and excellent surface conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

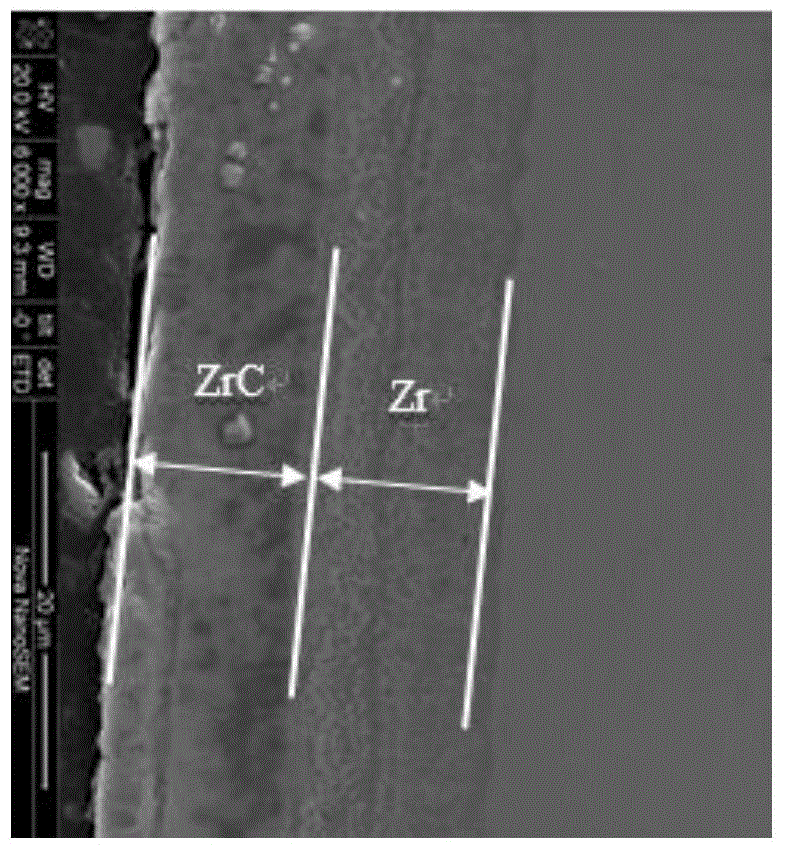

[0033] A method for preparing a titanium alloy bipolar plate nanocrystalline ZrC / Zr composite coating for a proton exchange membrane fuel cell, comprising the steps of:

[0034] (1) Ultrasonic cleaning of Ti-6A1-4V bipolar plate (titanium alloy bipolar plate substrate) after fine grinding with sandpaper;

[0035] (2) Put the ultrasonically cleaned titanium alloy bipolar plate as a workpiece into a double-cathode plasma sputtering deposition furnace, connect it to a controllable cathode device; connect the sputtering target to another controllable cathode device ;The distance between target and workpiece is 10mm;

[0036] (3) Vacuumize the double-cathode plasma sputtering deposition furnace to 5×10 -3 Pa, pass the argon gas with a gas flow rate of 30sccm to 40sccm into the furnace to keep the pressure in the furnace at 35Pa;

[0037] (4) Use a Zr powder metallurgy sintered plate with a purity of 99.99% as the sputtering target, open the cathode connected to the target and the...

Embodiment 2

[0045] Another set of process parameters is adopted: the distance between the target and the workpiece is 16mm, the air pressure in the double-cathode plasma sputtering deposition furnace is 40Pa, the sputtering deposition conditions of the Zr sintered plate are: target voltage 700V, target current 0.9A, workpiece The voltage is 250V, the workpiece current is 0.5A, the deposition temperature is 700°C, and the deposition time is 1.5 hours; the sputtering deposition conditions of the ZrC sintered plate are: target voltage 750V, target current 0.9A, workpiece voltage 250V, workpiece current 0.5A, The deposition temperature was 650°C, and the deposition time was 1.5 hours to obtain a nanocrystalline ZrC / Zr composite coating deposited by sputtering on the surface of the Ti-6A1-4V bipolar plate.

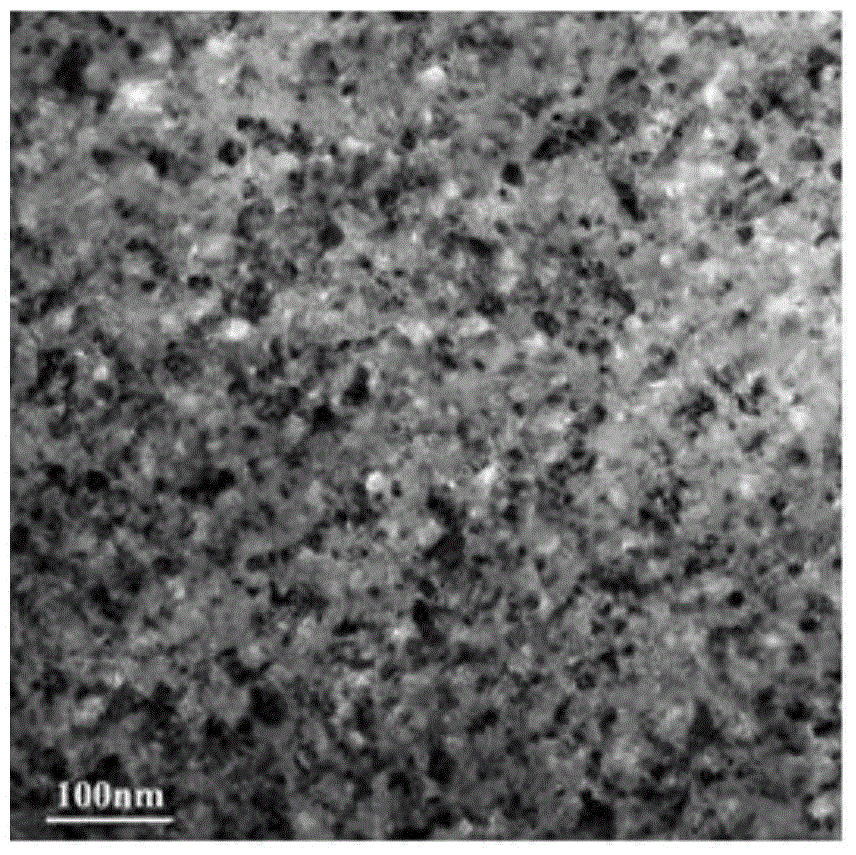

[0046] The nanocrystalline ZrC / Zr composite coating prepared in this embodiment is composed of an outer ZrC deposition layer (the mass fraction of ZrC is greater than 98%) with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com