Technique for preparing cerium corrosion-resistant film on surface of aluminum alloy

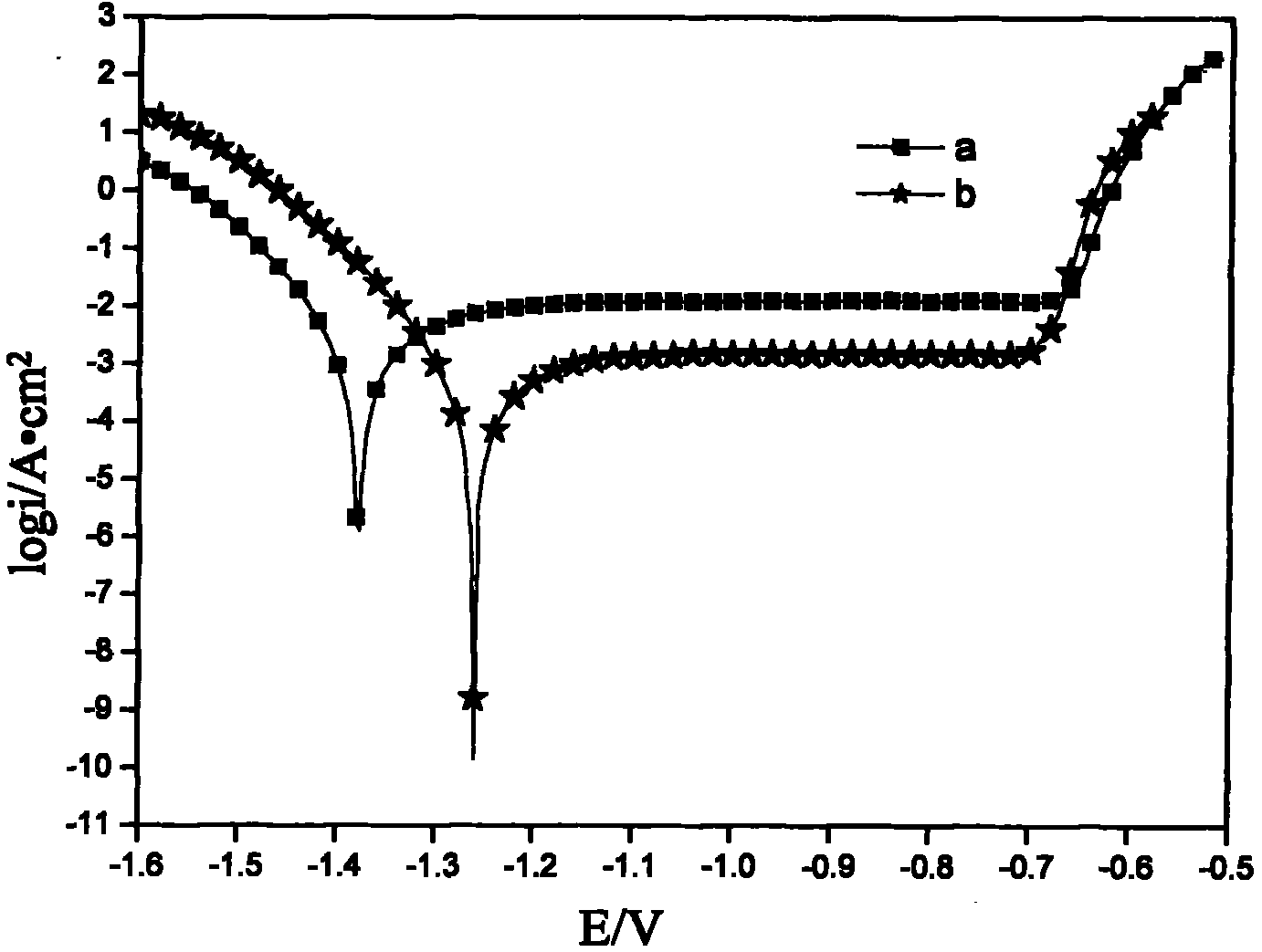

A technology of aluminum alloy surface and preparation process, applied in the direction of metal material coating process, etc., can solve the problems of non-dense corrosion-resistant film layer, high temperature required, long processing time, etc., achieve fast film forming speed and reduce corrosion current , the effect of high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

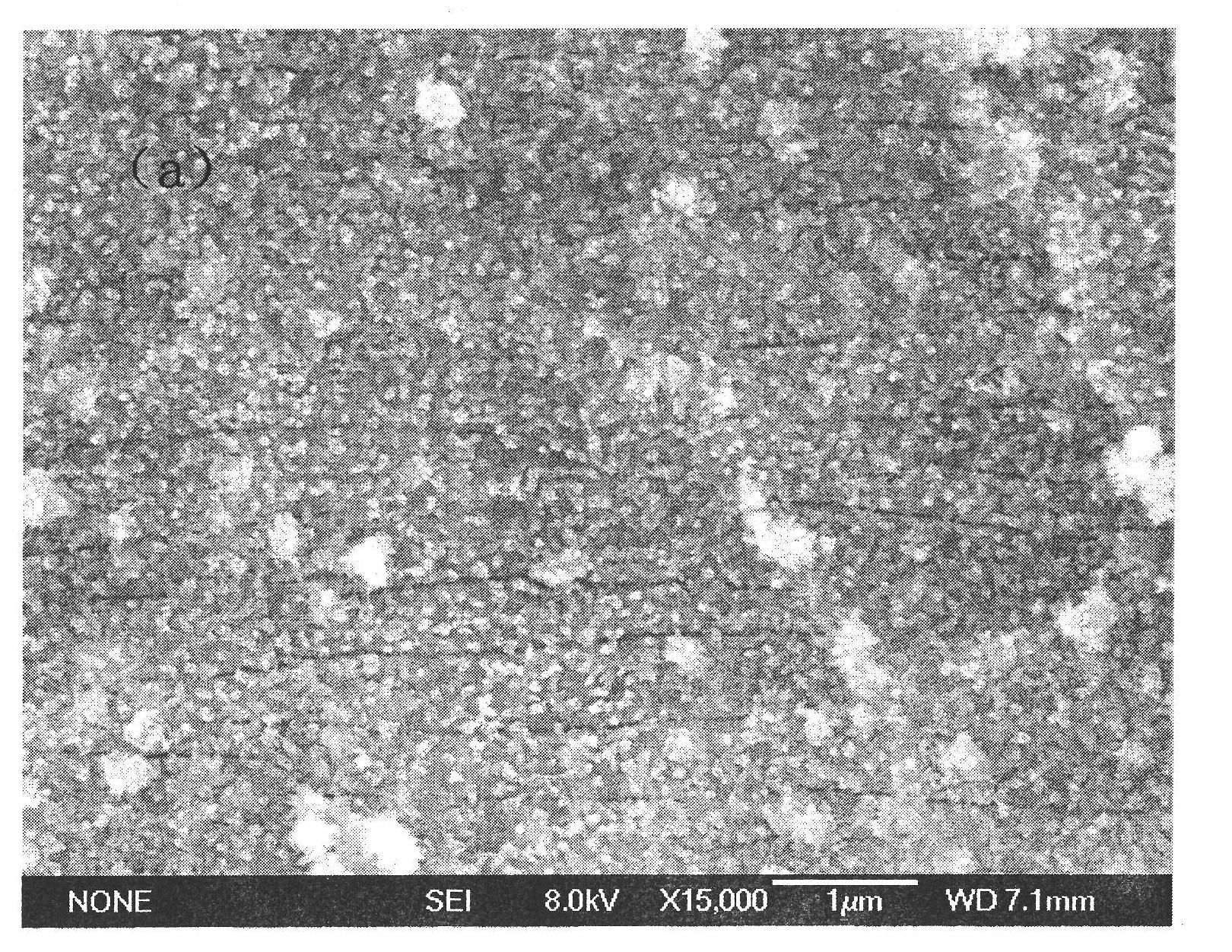

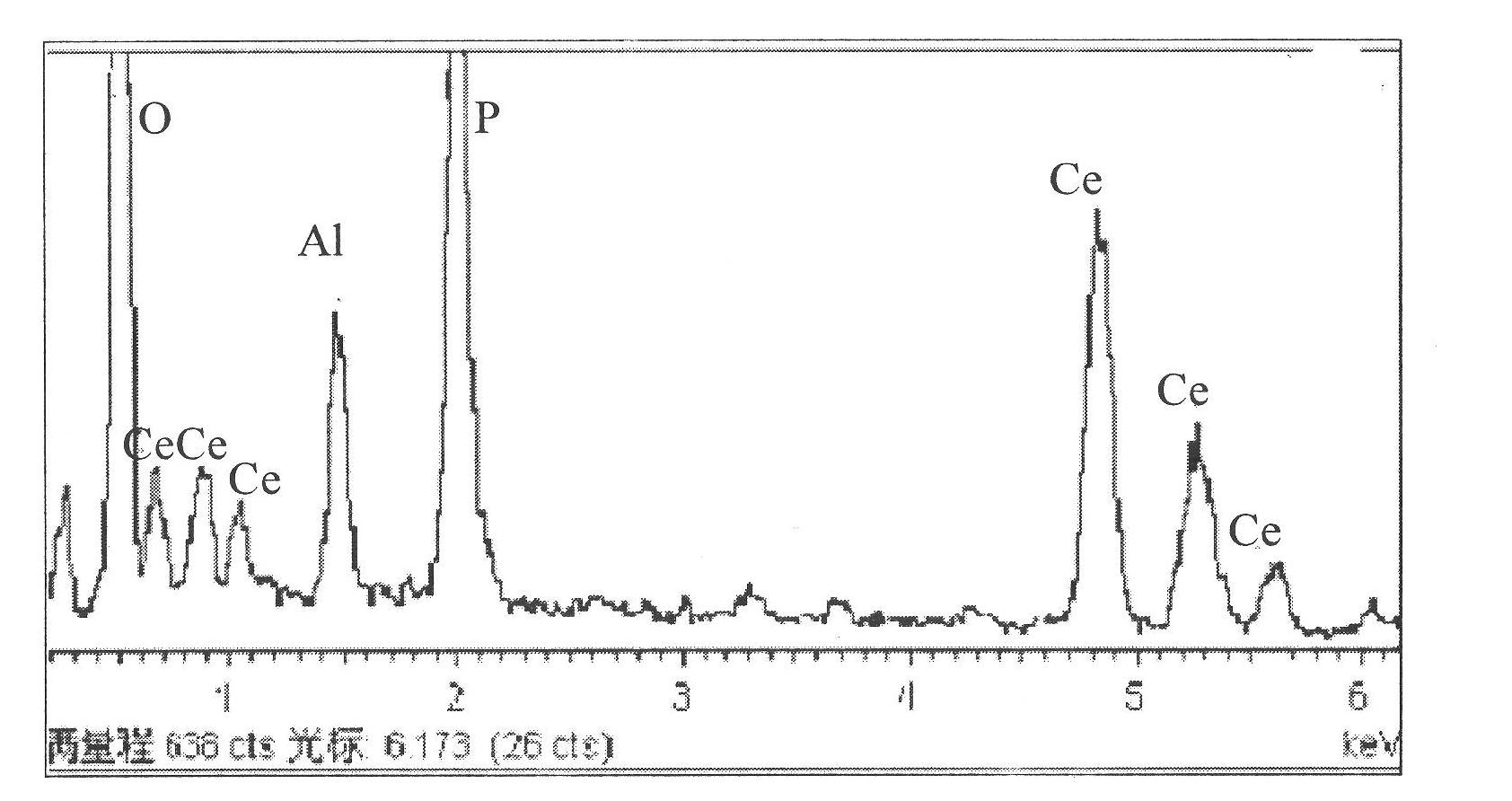

[0021] Preparation of Cerium Corrosion-resistant Film on Surface of 1060 Aluminum Alloy

[0022] First, the surface of 1060 aluminum alloy is pretreated. The steps are: polish the aluminum alloy with water-resistant sandpaper until it is bright, and rinse it with deionized water; soak it in a weak alkaline aqueous solution for 4 minutes at room temperature and then rinse it with deionized water. The alkaline aqueous solution contains 50 g / L of sodium phosphate, 10 g / L of sodium hydroxide, and 30 g / L of sodium silicate. Rinse with deionized water after soaking in alkaline aqueous solution at 50°C for 3 minutes, the alkaline aqueous solution contains sodium hydroxide 50g / L; Rinse with water.

[0023] Subsequently, the pretreated 1060 aluminum alloy was immersed in the cerium salt conversion liquid, and reacted at room temperature for 5 minutes. The components in the cerium salt conversion solution are: 40 g / L of cerous chloride hydrate, 50 g / L of hydrogen peroxide, 80 g / L of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com