Copper alloy passivation solution and passivation layer preparation method

A technology of copper alloy and passivation solution, which is applied in anodic oxidation and other directions, can solve the problems of film corrosion resistance and comprehensive application performance gap, and achieve the effects of low cost, convenient operation and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

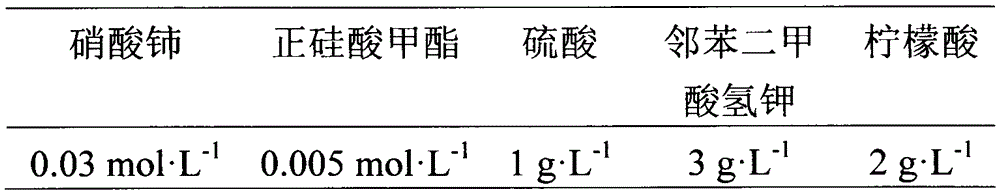

[0024] 1) Preparation of passivation solution: a solution containing cerium nitrate, sulfuric acid, potassium hydrogen phthalate and citric acid was used as passivation solution, and the concentration of each component was shown in Table 1.

[0025] Table 1 passivation solution composition

[0026]

[0027] When preparing the copper alloy passivation solution, prepare the substances other than methyl orthosilicate with distilled water according to the required amount, then add the required concentration of orthosilicate methyl ester to the prepared solution, and passivate the passivation solution with magnetic force Stirrer at 200r·min -1 Stir at a certain stirring speed for 5 minutes to make it fully hydrolyzed. During the stirring process, the temperature of the passivation solution is kept at 40°C with a constant temperature water bath.

[0028] 2) Preparation and pretreatment of the working electrode: the base material used in the present invention is copper sheet (cop...

Embodiment 2

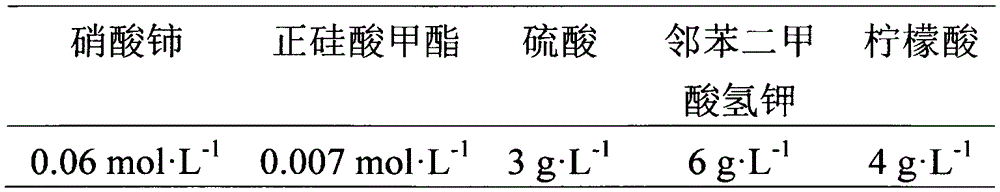

[0031] 1) Preparation of passivation solution: a solution containing cerium nitrate, sulfuric acid, potassium hydrogen phthalate and citric acid was used as passivation solution, and the concentration of each component was shown in Table 2.

[0032] Table 2 passivation solution composition

[0033]

[0034] When preparing the passivation solution, prepare the substances other than methyl orthosilicate with distilled water according to the required amount, then add the required concentration of orthosilicate methyl ester to the prepared solution, and use a magnetic stirrer to mix the passivation solution At 200r·min -1 Stir at a certain stirring speed for 5 minutes to fully dissolve various substances. During the stirring process, the temperature of the passivation solution is kept at 60°C with a constant temperature water bath.

[0035] 2) Preparation and pretreatment of the working electrode: the base material used in the present invention is a nickel-copper alloy sheet. ...

Embodiment 3

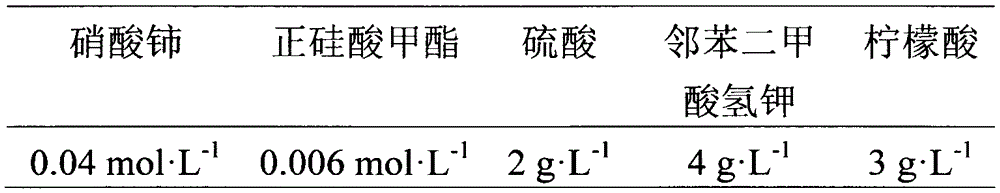

[0038] 1) Preparation of passivation solution: a solution containing cerium nitrate, sulfuric acid, potassium hydrogen phthalate and citric acid was used as passivation solution, and the concentration of each component was shown in Table 3.

[0039] Table 3 passivation solution composition

[0040]

[0041] When preparing the passivation solution, prepare the substances other than methyl orthosilicate with distilled water according to the required amount, then add the required concentration of orthosilicate methyl ester to the prepared solution, and use a magnetic stirrer to mix the passivation solution At 200r·min -1 Stir at a certain stirring speed for 5 minutes to fully dissolve various substances. During the stirring process, the temperature of the passivation solution is kept at 50°C with a constant temperature water bath.

[0042] 2) Preparation and pretreatment of the working electrode: the base material used in the present invention is a tin-copper alloy sheet. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com