Method for preparing novel conductive composite anticorrosive coating

A technology of anti-corrosion coating and preparation process, which is applied in the field of preparation of new conductive composite anti-corrosion coatings, and can solve problems such as poor solubility, difficult processing, and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

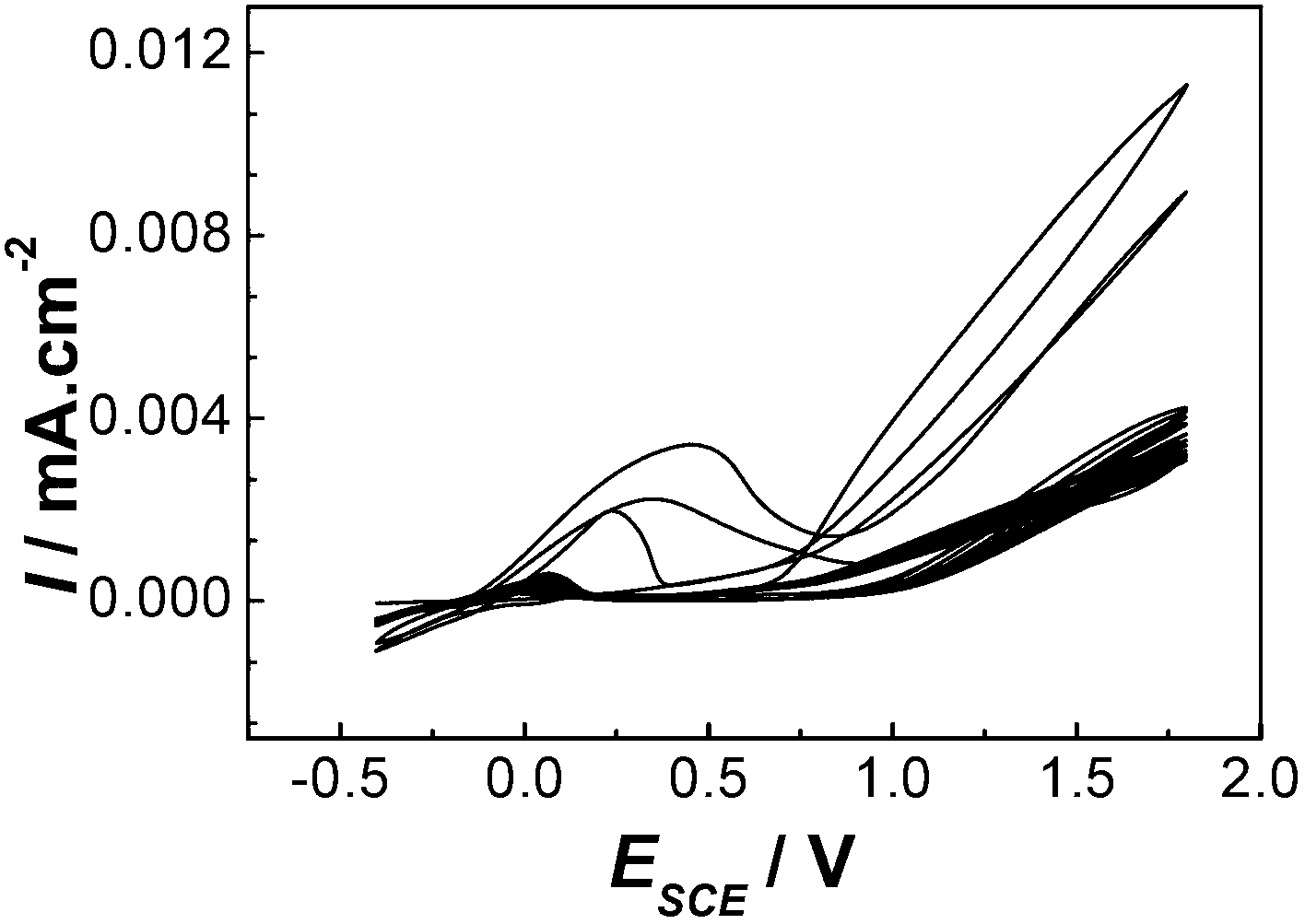

[0026] 1:: 0.01mol p-toluenesulfonic acid is dissolved in 200ml water and is mixed with solution, adjusts the pH of this solution with NaOH solution to be 1.0, obtains solution A;

[0027] 2: Add 0.01M pyrrole and 0.1M aniline monomer to solution A, and pass nitrogen gas for 10 minutes to obtain solution B;

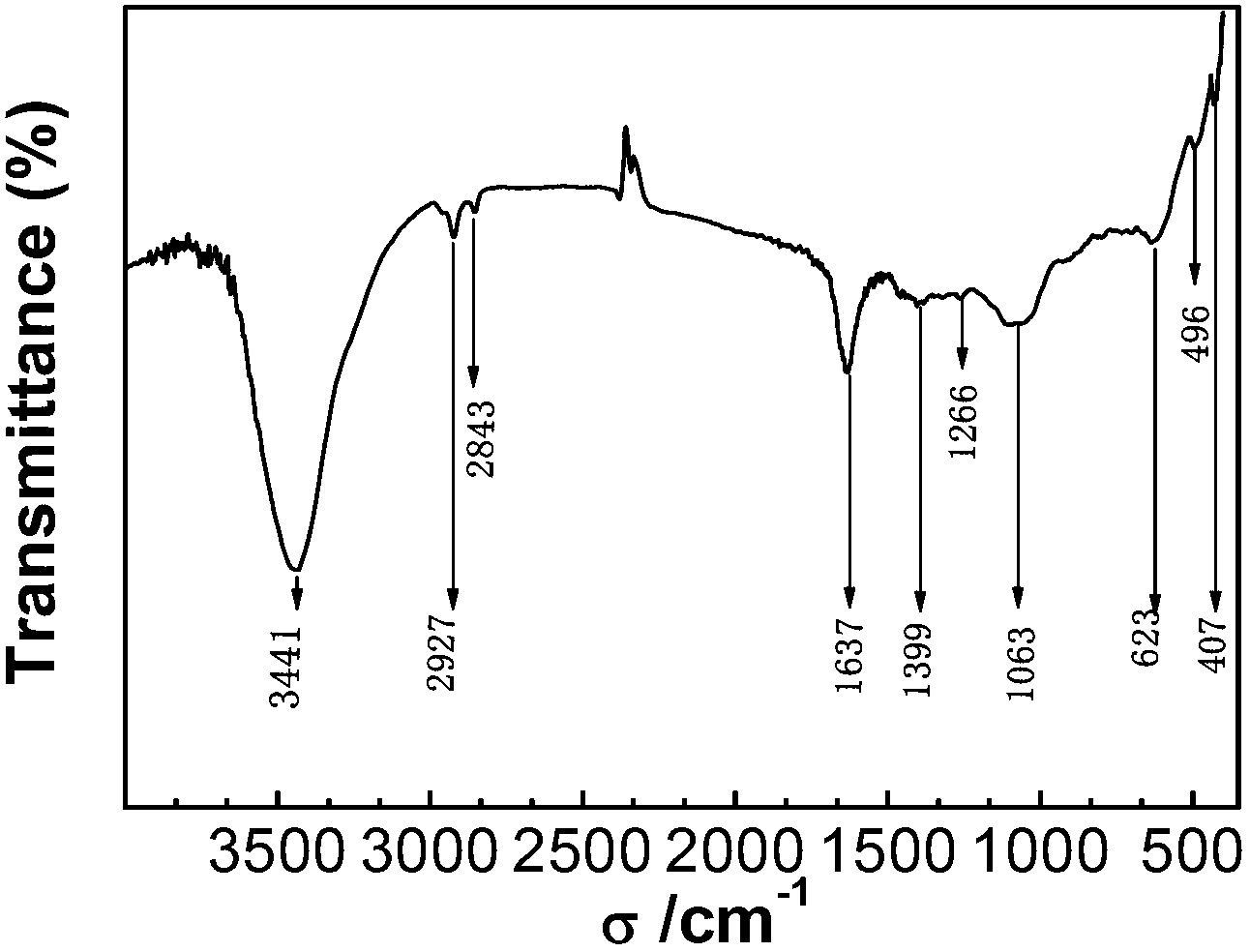

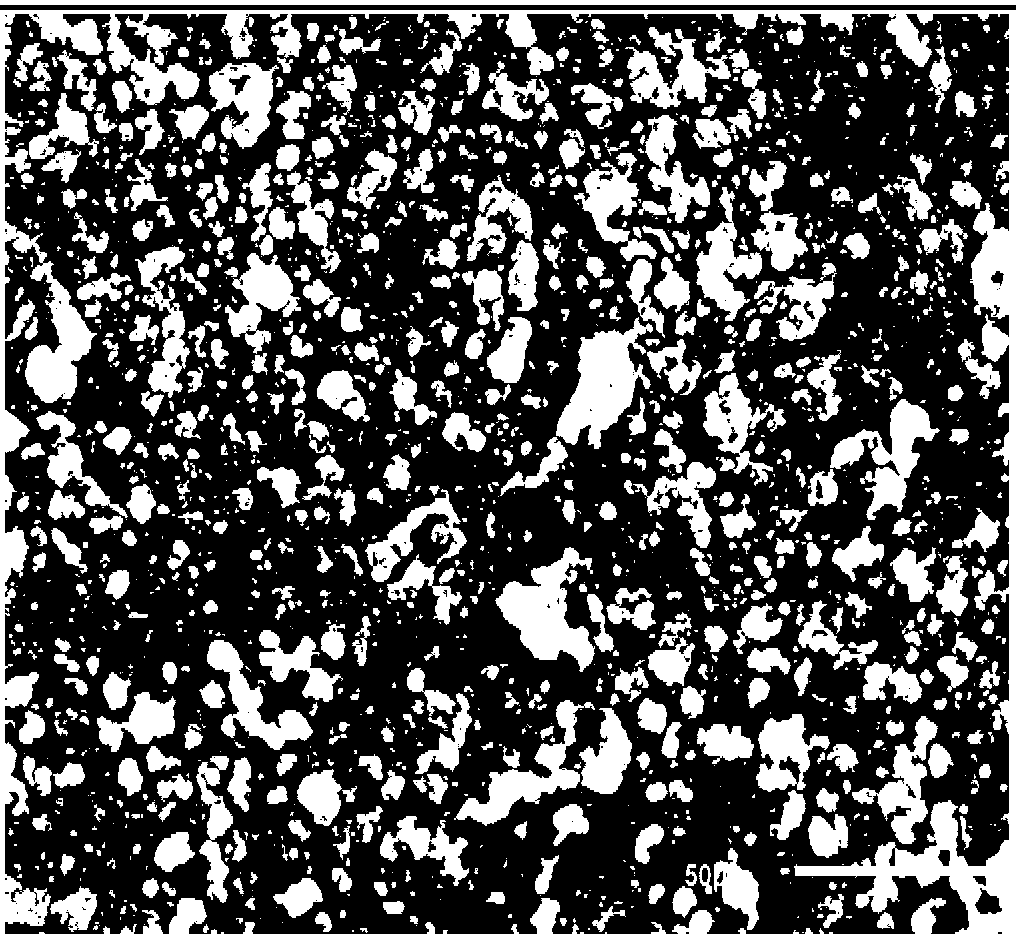

[0028] 3: In the three-electrode electrolytic cell, the treated copper substrate is used as the working electrode, the platinum sheet is used as the auxiliary electrode, the saturated calomel electrode is used as the reference electrode, and the solution B is used as the supporting electrolyte, and the cyclic voltammetry is used for polymerization, scanning Speed: 10mV / s, cycle times: 5 times. Rinse with distilled water after synthesis and dry to obtain a layer of high-density composite conductive polymer film C on the copper surface to be protected.

Embodiment 2

[0030] 1:: 0.02mol p-toluenesulfonic acid is dissolved in 200ml water and is prepared into a solution, and the pH of the solution is adjusted to 2.0 with NaOH solution to obtain solution A;

[0031] 2: Add 0.02M pyrrole and 0.1M aniline monomer to solution A, and pass nitrogen gas for 10 minutes to obtain solution B;

[0032] 3: In the three-electrode electrolytic cell, the treated copper substrate is used as the working electrode, the platinum sheet is used as the auxiliary electrode, the saturated calomel electrode is used as the reference electrode, and the solution B is used as the supporting electrolyte, and the cyclic voltammetry is used for polymerization, scanning Speed: 20mV / s, number of cycles: 10 times. Rinse with distilled water after synthesis and dry to obtain a layer of high-density composite conductive polymer film C on the copper surface to be protected.

Embodiment 3

[0034] 1:: 0.03mol p-toluenesulfonic acid was dissolved in 200ml water to prepare a solution, and the pH of the solution was adjusted to 3.0 with NaOH solution to obtain solution A;

[0035] 2: Add 0.02M pyrrole and 0.04M aniline monomer to solution A, and pass nitrogen gas for 10 minutes to obtain solution B;

[0036] 3: In the three-electrode electrolytic cell, the treated copper substrate is used as the working electrode, the platinum sheet is used as the auxiliary electrode, the saturated calomel electrode is used as the reference electrode, and the solution B is used as the supporting electrolyte, and the cyclic voltammetry is used for polymerization, scanning Speed: 30mV / s, cycle times: 15 times. Rinse with distilled water after synthesis and dry to obtain a layer of high-density composite conductive polymer film C on the copper surface to be protected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com