Method for preparing super-hydrophobic coating based on electrodeposition method, and application of super-hydrophobic coating

A super-hydrophobic coating and electrodeposition technology, applied in coatings, electrolytic coatings, building components, etc., can solve problems such as increasing the difficulty of grid corrosion protection work, and achieve good grid anti-corrosion effect, increased corrosion potential, and wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

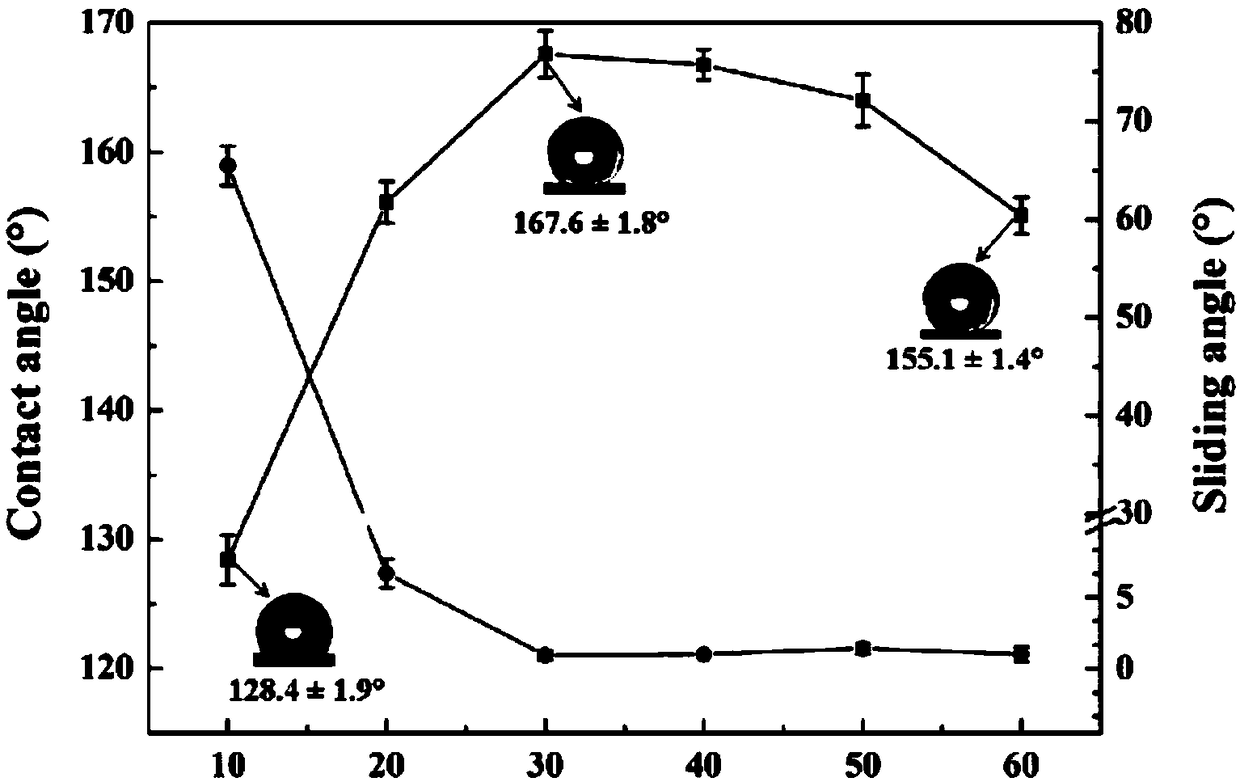

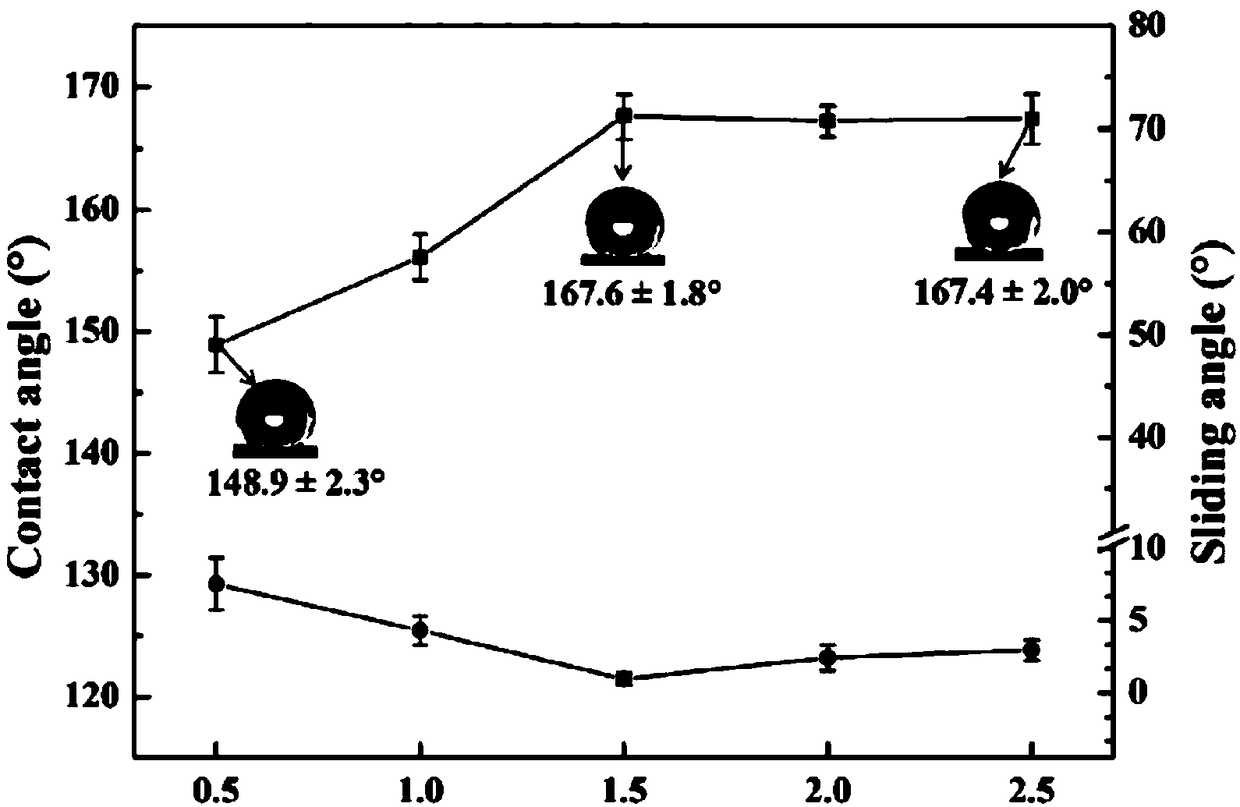

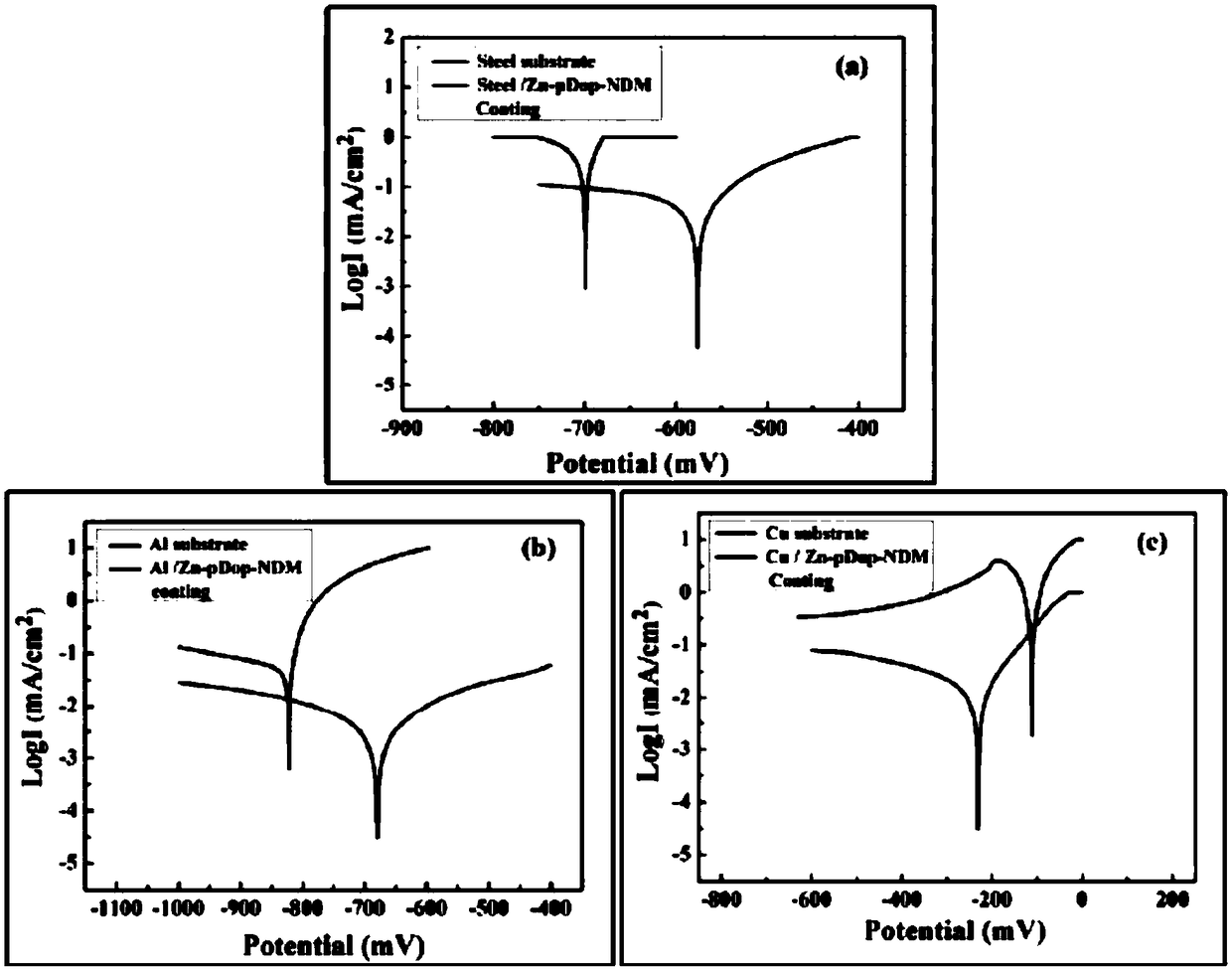

[0018] A method for preparing a superhydrophobic coating based on an electrodeposition method, comprising the following steps: 1. Electrode pretreatment: the steel electrode is polished on a polishing paper, and then the polished steel electrode is cleaned with laboratory-made deionized water Clean, then polish with aluminum powder to further remove a large amount of oil, and then rinse again with deionized water made in the laboratory. After rinsing, put it in a beaker filled with ethanol and put it in an ultrasonic cleaner Ultrasound for 15 minutes, then cleaned with a large amount of deionized water, dried, sealed with a parafilm, and set aside; 2. Preparation of electrolyte: First, weigh 30 mg of graphene and dissolve it with 30 ml of deionized water. Seal the sealing film, put it into an ultrasonic cleaner and perform ultrasonication for 1 hour, until the graphene is in a pulverized state, and make a graphene aqueous dispersion for use; 3. Electrodeposition of graphene: ad...

Embodiment 2

[0026] A method for preparing a superhydrophobic coating based on an electrodeposition method, comprising the following steps: 1. Electrode pretreatment: the steel electrode is polished on a polishing paper, and then the polished steel electrode is cleaned with laboratory-made deionized water Clean, then polish with aluminum powder to further remove a large amount of oil, and then rinse again with deionized water made in the laboratory. After rinsing, put it in a beaker filled with ethanol and put it in an ultrasonic cleaner Ultrasound for 15 minutes, then cleaned with a large amount of deionized water, dried, sealed with a parafilm, and set aside; 2. Preparation of electrolyte: First, weigh 30 mg of graphene and dissolve it with 30 ml of deionized water. Seal the sealing film, put it into an ultrasonic cleaner and perform ultrasonication for 1 hour, until the graphene is in a pulverized state, and make a graphene aqueous dispersion for use; 3. Electrodeposition of graphene: ad...

Embodiment 3

[0031] A method for preparing a superhydrophobic coating based on an electrodeposition method, comprising the following steps: 1. Electrode pretreatment: the steel electrode is polished on a polishing paper, and then the polished steel electrode is cleaned with laboratory-made deionized water Clean, then polish with aluminum powder to further remove a large amount of oil, and then rinse again with deionized water made in the laboratory. After rinsing, put it in a beaker filled with ethanol and put it in an ultrasonic cleaner Ultrasound for 15 minutes, then cleaned with a large amount of deionized water, dried, sealed with a parafilm, and set aside; 2. Preparation of electrolyte: First, weigh 30 mg of graphene and dissolve it with 30 ml of deionized water. Seal the sealing film, put it into an ultrasonic cleaner and perform ultrasonication for 1 hour, until the graphene is in a pulverized state, and make a graphene aqueous dispersion for use; 3. Electrodeposition of graphene: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com