Preparation method of icing-resistant/ corrosion-resistant integrated functional super-hydrophobic coating for aviation

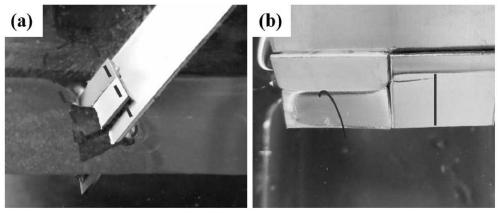

A super-hydrophobic coating and anti-icing technology, applied in anti-corrosion coatings, coatings, devices for coating liquids on the surface, etc., can solve the problems of aircrafts that are easy to freeze, metals that are easy to be corroded, and not resistant to corrosion. Achieve good low temperature water repellency, small ice layer viscosity strength, and prevent freezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

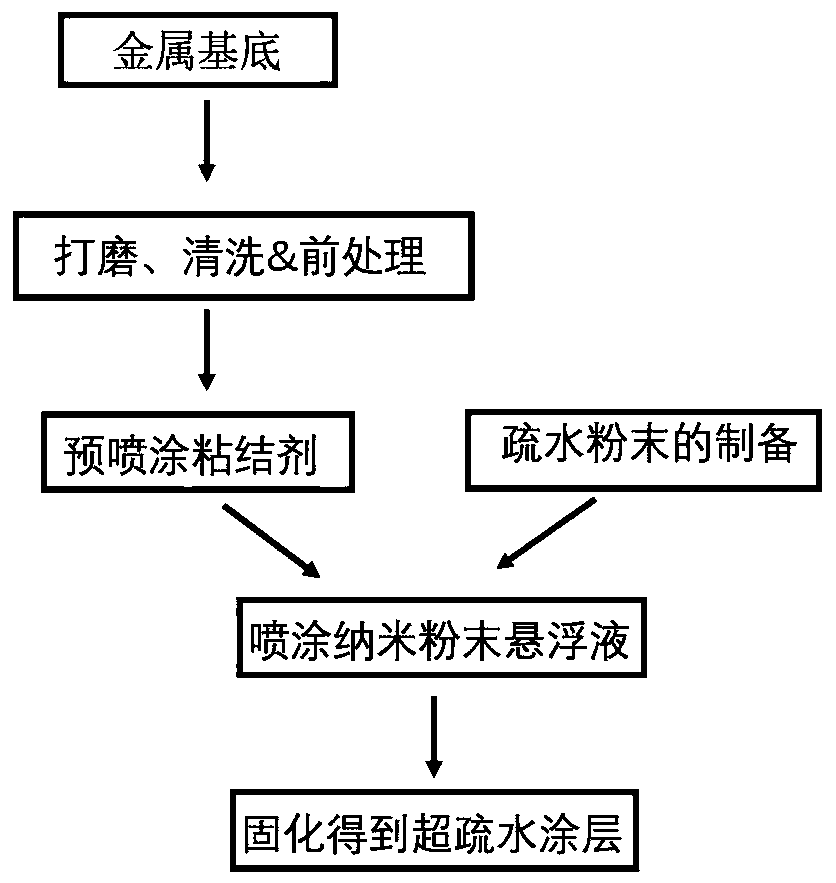

Method used

Image

Examples

Embodiment 1

[0030] First, the regularly cut aluminum sheet (1 cm × 1 cm × 1 mm) was ultrasonically cleaned with acetone and alcohol for 15 min to remove the oil on the surface, and then dried in nitrogen. Firstly put the aluminum flakes at 5g·L -1 Solvothermal reaction at 80 °C for 5 h in NaOH solution, followed by washing with ethanol, and then in 20 g L -1 Chemically etch in HF for 15 minutes, clean and set aside.

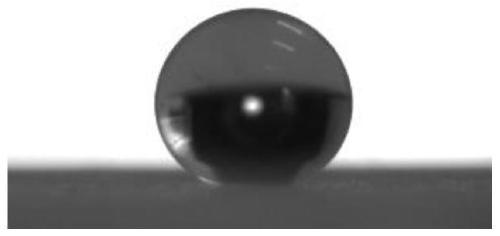

[0031] Weigh 1.0g SiO2 2 The nanoparticles were added to 20 mL of sodium hydroxide solution (the mass volume ratio of sodium hydroxide to deionized water was 1:10 g / ml), and ultrasonically dispersed for 10 min. SiO 2 The suspension was added dropwise to a 2wt% perfluorodecyltrichlorosilane solution, and 10 mL of KH-570 silane coupling agent was added, and stirred at room temperature to promote the hydrolysis and condensation reaction. After the reaction, the reaction product was centrifuged at 8000-10000 rpm for 10 min, washed with absolute ethanol and centrifuged twice....

Embodiment 2

[0036] First, the regularly cut aluminum sheet was ultrasonically cleaned with acetone and alcohol for 10 min to remove the oil on the surface, and then dried in nitrogen. Aluminum flakes in 25g·L-1 NaOH and 25g·L -1 Na 2 CO 3 In the mixed solution of 60 ℃ alkali washing 0.5min, followed by 300g L -1 HNO 3 Pickling at room temperature for 3 minutes in the solution, repeating the water washing operation -1 h 3 PO 4 The anodic oxidation was carried out for 20 minutes under the applied working voltage of 10V in the solution, and then, the aluminum sheet was cleaned with anhydrous ethanol and dried in a nitrogen atmosphere for later use.

[0037] Measure 0.5mL perfluorodecyltriethoxysilane into 100mL ethanol, after magnetic stirring, add 5mL ethyl orthosilicate, then add 2.0g TiO 2 nanoparticles and 2.0g Al 2 o 3 Nanoparticles were then sonicated for 10 min and stirred continuously at 40 °C for 24 h. After the reaction, the reaction product was centrifuged at 10000 rpm f...

Embodiment 3

[0040] The aluminum flakes were first ultrasonically cleaned and dried under nitrogen. Subsequently, a laser was used to etch a regular array structure on the cleaned aluminum sheet, and the aluminum sheet was cleaned with absolute ethanol and dried in a nitrogen atmosphere for later use.

[0041] Measure 5mL of tridecafluorooctyltrimethoxysilane into 200mL of ethylene glycol, add 5mL of ethyl orthosilicate, stir well, then add 5.0g of SiO 2 Nanoparticles, sonicated for 10 min, and kept stirring at room temperature for 48 h. After the reaction, the reaction product was centrifuged at 10,000 rpm for 8 min, washed with absolute ethanol and centrifuged twice. Subsequently, the centrifuged product was vacuum-dried at 60°C for 24 hours to obtain hydrophobic SiO 2 nanoparticles.

[0042] Spray epoxy resin on the above-mentioned aluminum sheet, place it in an oven at 80°C for pre-curing for 1h, and then weigh 0.1g of the above-mentioned hydrophobic SiO 2 The nanoparticles were ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com