Preparation method of chromium-free dacromet coating

A technology of mixing solution and acetone, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of strict restrictions on the use of chromium, and achieve the effects of small corrosion current, strong corrosion resistance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

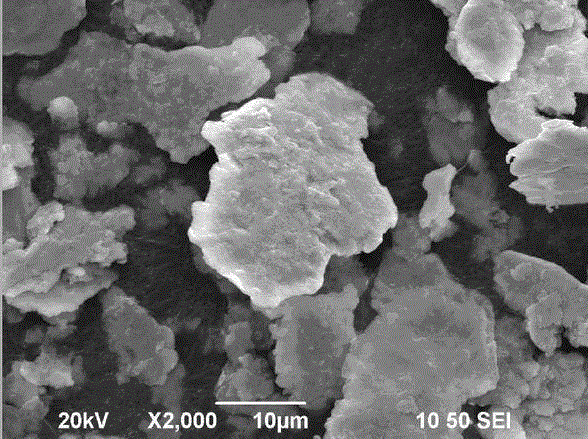

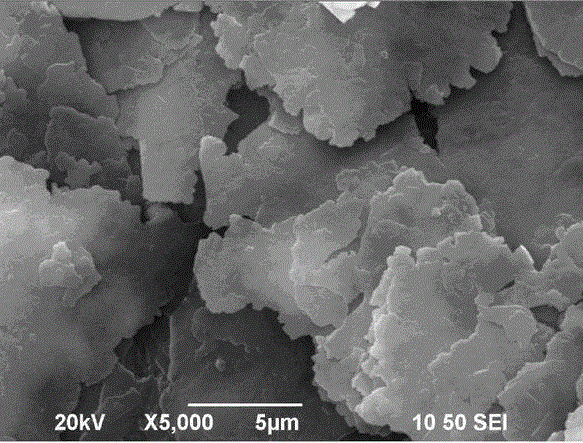

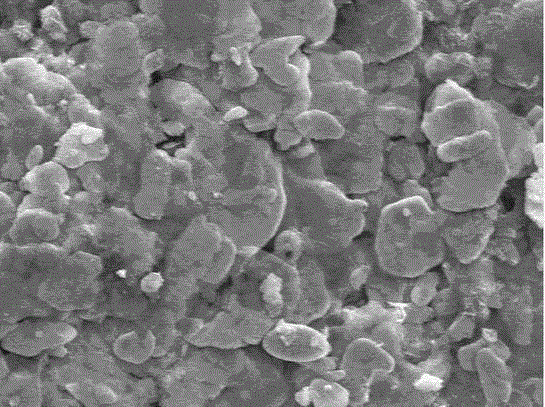

Image

Examples

Embodiment 1

[0024] (1) Dissolve 3.5g of thickener hydroxyethyl cellulose in a mixed solution of 30mL of acetone and 30mL of isopropanol, then add 4.77g of polyethylene glycol, 1.0g of ethylene glycol, and 3.0g of polytetrafluoroethylene in sequence , 4.6mL surfactant OP-10 and 2-3 drops of polyether modified silicone defoamer (different stirring or adding process may produce foam, depending on whether foam is generated, selectively add polyether modified silicone Defoamer, the amount of polyether modified silicone defoamer to be added dropwise depends on the amount of foam produced, the following is the same as above), after stirring and mixing evenly, add 80g of scaly zinc powder and 13g of scaly aluminum powder to obtain component A;

[0025] (2) Dissolve 8g of sodium oxalate, 10g of citric acid and 1.3g of boric acid in 30mL of distilled water, then dropwise add 0.5mL of oxidant hydrogen peroxide, stir and mix evenly to obtain component B;

[0026] (3) Add component B to component A un...

Embodiment 2

[0028] (1) Dissolve 3.5g of thickener hydroxyethyl cellulose in a mixed solution of 30mL of acetone and 30mL of isopropanol, then add 4.77g of polyethylene glycol, 1.0g of ethylene glycol, and 3.0g of polytetrafluoroethylene in sequence , 4.6mL of surfactant OP-10 and 2-3 drops of polyether modified silicone defoamer, stir and mix evenly, add 78g of flaky zinc powder and 13g of flaky aluminum powder to obtain component A;

[0029] (2) Dissolve 8g of sodium oxalate, 10g of citric acid and 1.3g of boric acid in 30mL of distilled water, then dropwise add 0.5mL of oxidant hydrogen peroxide, stir and mix evenly to obtain component B;

[0030] (3) Add component B to component A under stirring conditions, then add 1mL polyurethane modified epoxy resin and 1mL KH-570 silane coupling agent, stir and mix evenly to obtain chrome-free dacromet coating solution.

Embodiment 3

[0032] (1) Dissolve 3.5g of thickener hydroxyethyl cellulose in a mixed solution of 30mL of acetone and 30mL of isopropanol, then add 4.77g of polyethylene glycol, 1.0g of ethylene glycol, and 3.0g of polytetrafluoroethylene in sequence , 4.6mL of surfactant OP-10 and 2-3 drops of polyether modified silicone defoamer, stir and mix evenly, add 80g of flaky zinc powder and 13g of flaky aluminum powder to obtain component A;

[0033] (2) Dissolve 8.5g of sodium oxalate, 10g of citric acid and 1.3g of boric acid in 30mL of distilled water, then dropwise add 0.5mL of oxidant hydrogen peroxide, stir and mix evenly to obtain component B;

[0034] (3) Add component B to component A under stirring conditions, then add 1mL polyurethane modified epoxy resin and 1mL KH-570 silane coupling agent, stir and mix evenly to obtain chrome-free dacromet coating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com