Corrosion inhibitor of steel reinforced concrete

A technology for corrosion of reinforced concrete and steel bars, applied in the field of reagents with corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Treat concrete with a mixture of isobutyltriethoxysilane and diethylaminoethanol.

[0061] 980 g of isobutyltriethoxysilane and 20 g of diethanolamine were mixed and stirred at 40° C. for 30 minutes. The viscosity of the product is 1 mPas.

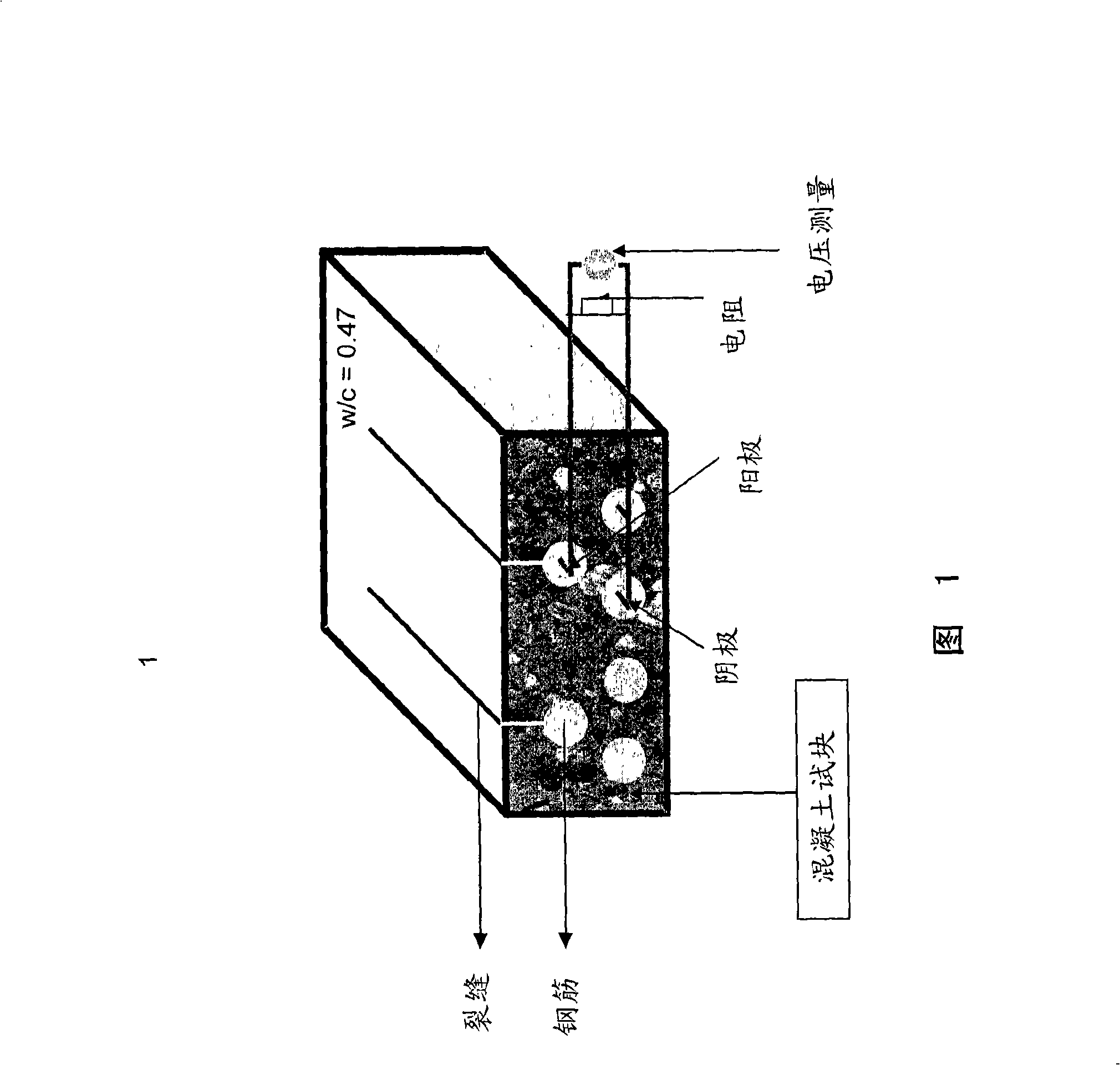

[0062] Reinforced concrete test blocks (30 x 30 x 18 cm) corresponding to Fig. 1 having artificial cracks on the upper side with cracks extending along the steel bars were treated with the liquid low-viscosity corrosion inhibitor described above for a period of about 65 days. For this reason, each time 180g / m 2 Spray the surface three times with the applied amount. The drying time between each spray application was 45 minutes. A plexiglass edge is then provided on the treated concrete surface. Seal the plexiglass edge to the concrete with a plastic sealant. A 15% by weight NaCl aqueous solution was filled into the groove thus formed. The makrozelle corrosion current was determined by means of Ohm's law by measuring the voltage...

Embodiment 2

[0070] Treat concrete with isobutyltriethoxysilane.

[0071] Reinforced concrete test pieces (30 x 30 x 18 cm) corresponding to Fig. 1 with artificial cracks for a period of about 65 days were treated with isobutyltriethoxysilane on the upper side with cracks extending along the reinforcement bars. The product purity was approximately 95% (GC WLD area percent). 180g / m each time 2 Spray the surface three times with the applied amount. The drying time between each spray application was 45 minutes. A plexiglass edge is then provided on the treated concrete surface. Seal the plexiglass edge to the concrete with a plastic sealant. A 15% by weight NaCl aqueous solution was filled into the groove thus formed. The large cell corrosion current is determined by means of Ohm's law by measuring the voltage drop across a 10 ohm resistor connected above and below the rebar. The concrete coupons were all brine loaded at about 20°C for 4 days to remove the salt solution and dried at abo...

Embodiment 3

[0079] Treatment of concrete with a mixture of oligopropylsiloxane and aminopropyltriethoxysilane

[0080] 980 g of oligomeric n-propylethoxysiloxane with an average molecular weight of about 600 g / mol and a viscosity of 5 mPas and 20 g of 3-aminopropyltriethoxysilane were mixed and stirred at 40° C. for 30 minutes. The viscosity of the product is about 5 mPas.

[0081] Reinforced concrete test blocks (30 x 30 x 18 cm) corresponding to Fig. 1 having artificial cracks on the upper side with cracks extending along the steel bars were treated with the liquid low-viscosity corrosion inhibitor described above for a period of about 65 days. For this purpose, each time about 200g / m 2 Spray the surface three times with the applied amount. The drying time between each spray application was 90 minutes. A plexiglass edge is then provided on the treated concrete surface. Seal the plexiglass edge to the concrete with a plastic sealant. A 15% by weight NaCl aqueous solution was filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com