Method for modifying proton exchange membrane fuel cell metal dual-polarity board

A technology of metal bipolar plates and proton exchange membranes, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulties in large-scale commercial application, unacceptable processing costs, corrosion of thin-layer metal plates, etc., and achieve accelerated commercialization. process, low processing cost, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

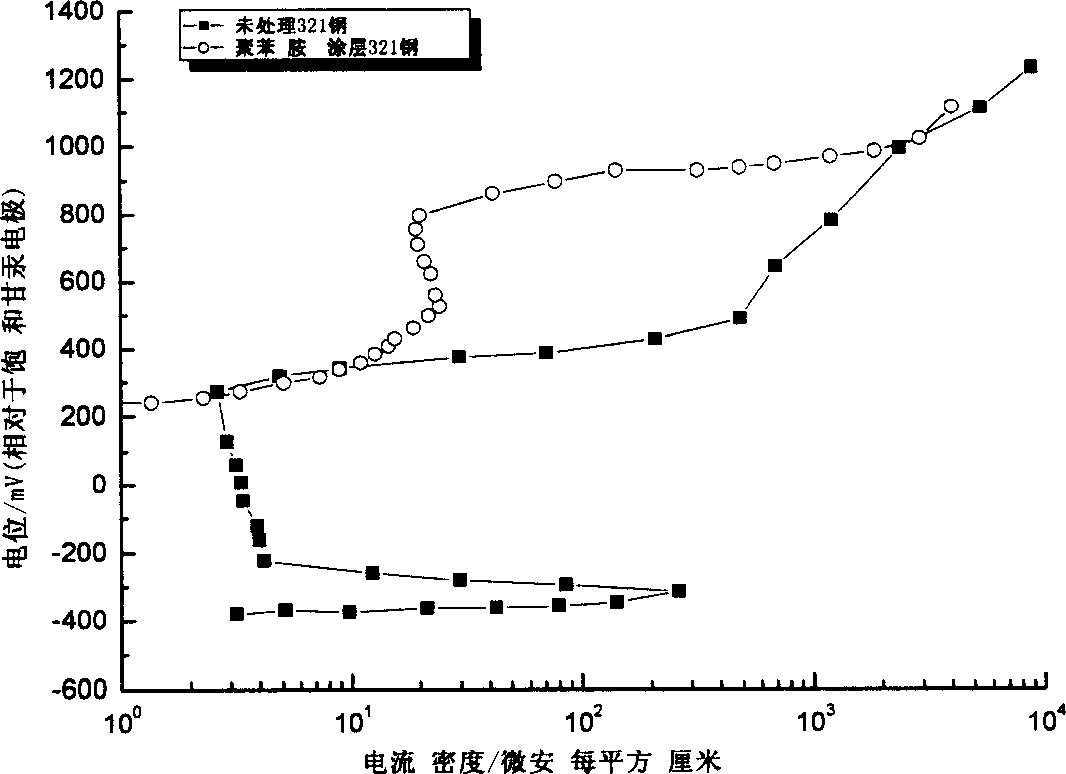

[0027] Take 1Cr18Ni9Ti stainless steel, after conventional grinding, water washing, alcohol washing, degreasing and drying, put it into 0.01mol / L oxalic acid + 0.1mol / L aniline solution with nitrogen for 30 minutes in advance, adopt pulse mode, use stainless steel as working electrode, The carbon plate is the counter electrode, the saturated calomel electrode is the reference electrode, pulse polyaniline (the potential of the cathode pulse is -200mV, the pulse time is 10s; the anode pulse potential is between 1200mV, the pulse time is 10s, and the number of continuous pulses can be for 15 times). The cross-sectional structure of the modified plate is shown in figure 1 , the inner layer is a thin metal plate, the outer layer is a conductive polymer, and the thickness is controlled by the polymerization time, ranging from a few microns to hundreds of microns. The modified plate was simulated in the anode environment of the battery (temperature 80°C, corrosion solution 0.01mol / L...

Embodiment 2

[0031] The difference from Example 1 is:

[0032] Take a 304 stainless steel plate, after conventional grinding, washing with water, washing with alcohol, degreasing and blowing dry, put it into a solution of 3mol / L sulfuric acid and 2.0mol / L aniline with nitrogen for 30 minutes in advance, use stainless steel as the working electrode, and a carbon plate as the counter electrode. Electrode, saturated calomel electrode as reference electrode, cyclic voltammetry scanning polyaniline (scanning interval -600mV-+800mV, scanning speed 10mV / s, scanning circle number 50 circles).

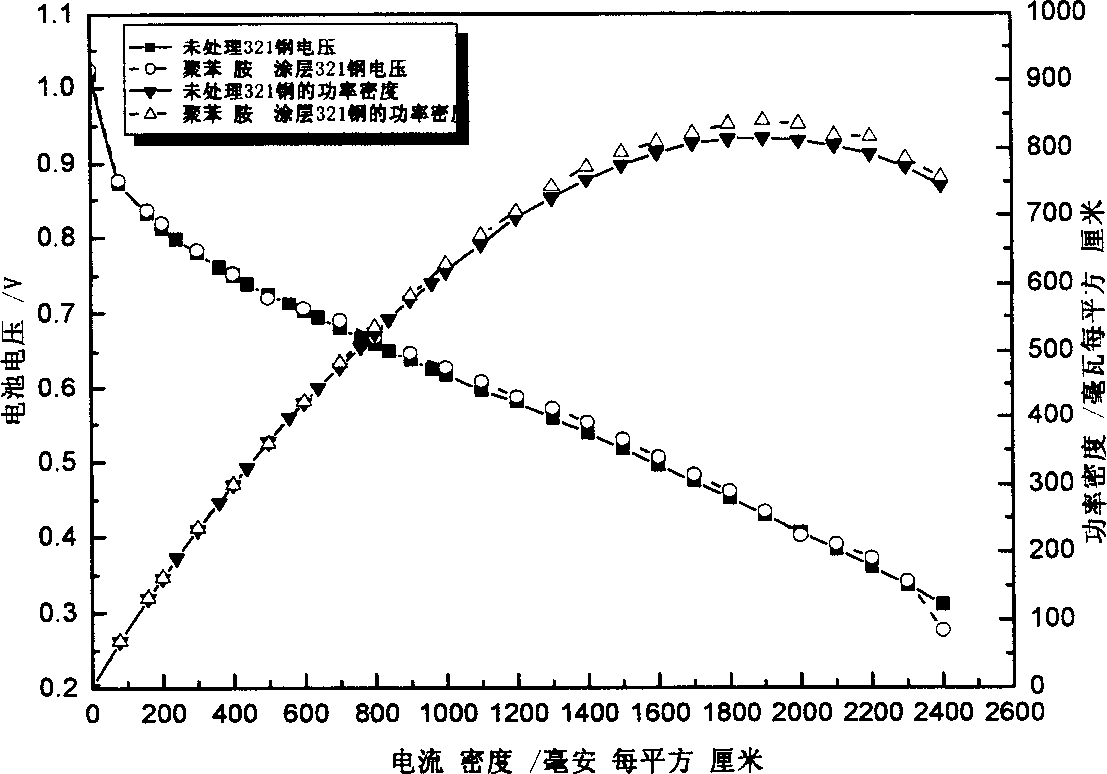

[0033] Results: After polyaniline modification, the corrosion potential of 304 stainless steel in the simulated corrosion solution was also increased by nearly 600mV, the passivation current density was reduced, and the corrosion resistance was also significantly improved (see Figure 4 ).

Embodiment 3

[0035] The difference from Example 2 is:

[0036] Put it into the 0.01mol / L perchloric acid and 0.15mol / L aniline solution pre-passed with nitrogen, use stainless steel as the working electrode, a carbon plate as the counter electrode, and a saturated calomel electrode as the reference electrode, and perform cyclic voltammetry scanning polymerization. Aniline (scan range -300mV-+1200mV, scan speed 100mV / s, scan circles 5 circles).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com