Bidirectional electroosmosis repairing method of corrosive concrete structure

A concrete structure and repair method technology, applied in the field of electrochemical repair, can solve the problem of low efficiency of harmful ion precipitation, achieve the effect of improving migration ability, convenient operation, and reducing corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

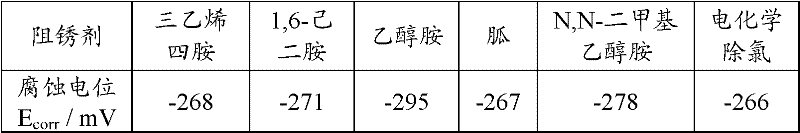

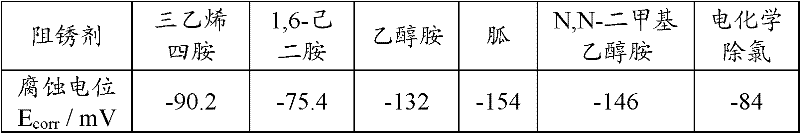

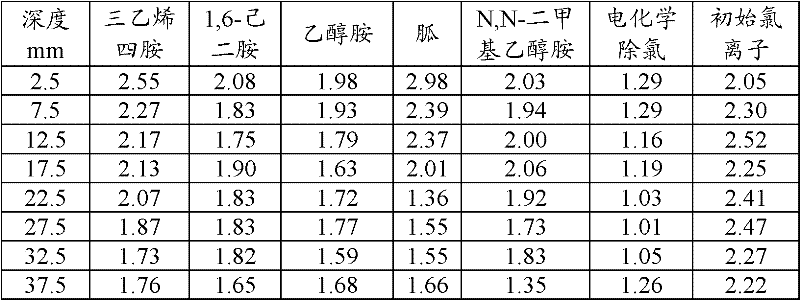

[0021] The mass ratio of each component in concrete is: cement: sand: gravel: water = 1: 1.40: 2.60: 0.49, that is, to prepare a cubic meter of fresh concrete, use 210kg of water, 429kg of cement, 600kg of medium sand, and 1115kg of particle size 5 ~ 18mm stones, mix 2% of the cement mass that is 8.58kg of sodium chloride during concrete casting, the water-cement ratio is 0.5, the depth of the protective layer is 40mm, the standard maintenance is 28 days, and after 5 months in the normal room , using the electrochemical workstation Reference600 to measure the electrochemical impedance spectrum and weak polarization curves of the steel bars in the concrete specimens before repair, and found that the steel bars have been corroded, and the data of the initial corrosion potential of the steel bars are shown in Table 1. At the same time, the chlorine ion content in the concrete specimen was measured by the rapid chloride ion test method (RCT). The initial test data are shown in Tabl...

Embodiment 2

[0025] The mass ratio of each component in concrete is: cement: sand: gravel: water = 1: 1.40: 2.60: 0.49, that is, to prepare a cubic meter of fresh concrete, use 210kg of water, 429kg of cement, 600kg of medium sand, and 1115kg of particle size 5 ~ 18mm stones, mix 2% of the cement mass that is 8.58kg of sodium chloride during concrete casting, the water-cement ratio is 0.5, the depth of the protective layer is 40mm, the standard maintenance is 28 days, and after 5 months in the normal room , using the electrochemical workstation Reference600 to measure the electrochemical impedance spectrum and weak polarization curves of the steel bars in the concrete specimens before repair, and found that the steel bars have been corroded, and the data of the initial corrosion potential of the steel bars are shown in Table 1. At the same time, the chlorine ion content in the concrete specimen was measured by the rapid chloride ion test method (RCT). The initial test data are shown in Tabl...

Embodiment 3

[0029] The mass ratio of each component in concrete is: cement: sand: gravel: water = 1: 1.40: 2.60: 0.49, that is, to prepare a cubic meter of fresh concrete, use 210kg of water, 429kg of cement, 600kg of medium sand, and 1115kg of particle size 5 ~ 18mm stones, mix 2% of the cement mass that is 8.58kg of sodium chloride during concrete casting, the water-cement ratio is 0.5, the depth of the protective layer is 40mm, the standard maintenance is 28 days, and after 5 months in the normal room , using the electrochemical workstation Reference600 to measure the electrochemical impedance spectrum and weak polarization curves of the steel bars in the concrete specimens before repair, and found that the steel bars have been corroded, and the data of the initial corrosion potential of the steel bars are shown in Table 1. At the same time, the chlorine ion content in the concrete specimen was measured by the rapid chloride ion test method (RCT). The initial test data are shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com