Method for preparing conducting polymer-perfluoropolyether oil complex phase coating

A technology of perfluoropolyether oil and conductive polymer, which is applied in coating, electrolytic coating, electrophoretic plating, etc., to achieve the effect of high hydrophobicity, good environmental stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

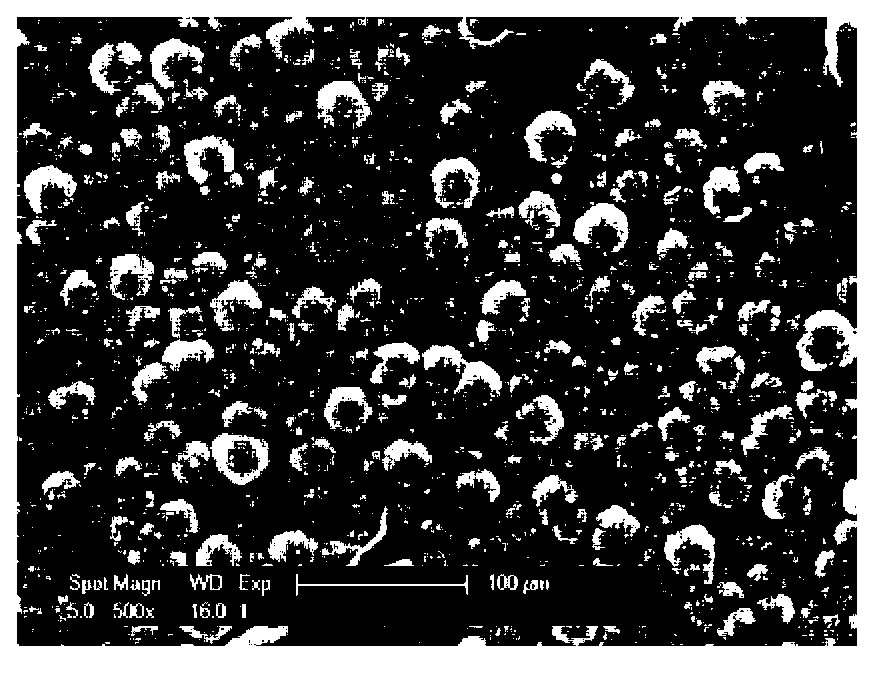

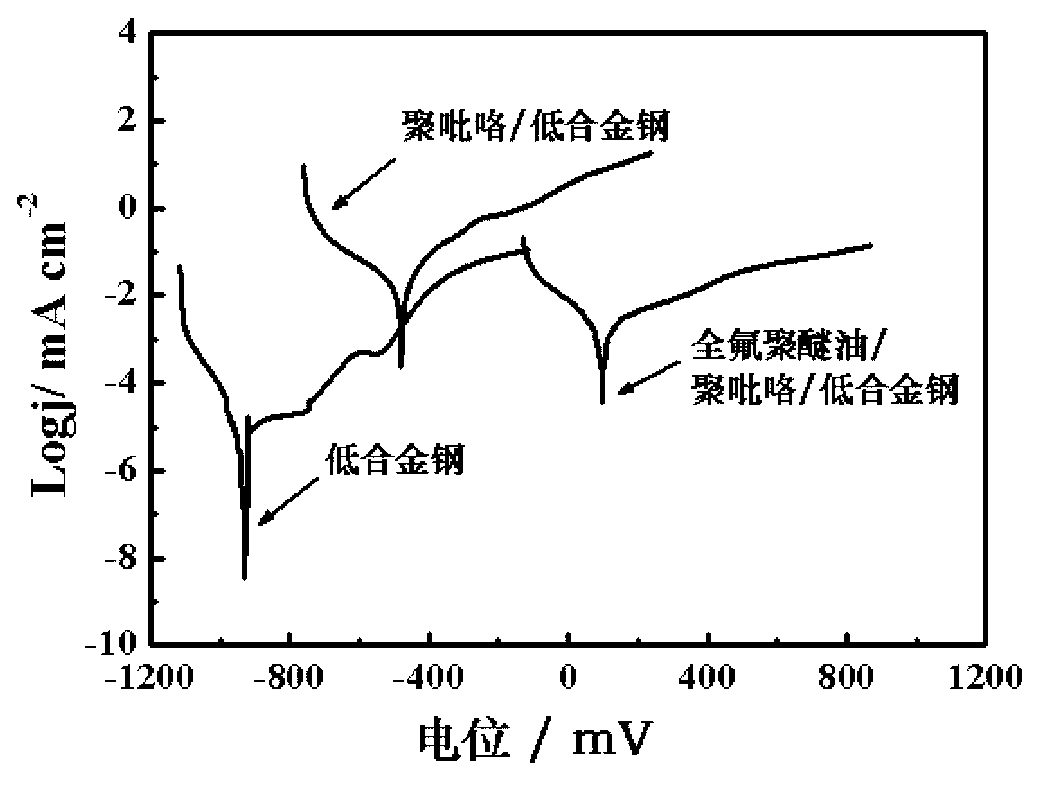

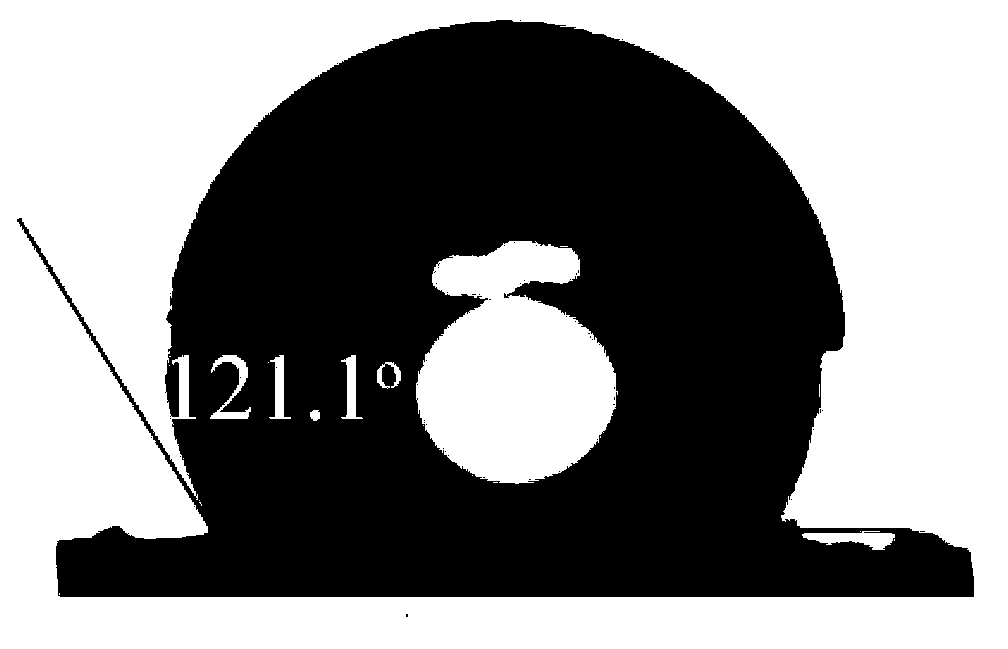

[0020] In this example, 0.2 mol of pyrrole monomer and 0.1 mol of sodium lauryl sulfate commercially available were put into 1 L of dedistilled water, stirred at a constant temperature at 25°C until completely dissolved to form an electrolyte solution, and a three-electrode system was used at a potential of 1.0V The constant potential polymerization was carried out under the condition of 15 minutes, and the polypyrrole film was obtained on the surface of the low-alloy steel working electrode. The prepared polypyrrole film was taken out from the electrolyte solution, rinsed repeatedly with distilled water, and placed in a vacuum oven at 60°C under vacuum. Dry 24h to obtain the polypyrrole / low-alloy steel composite material, and the microscopic appearance of the polypyrrole / low-alloy steel composite material is as follows: figure 1 Shown; Then the polypyrrole / low alloy steel composite is soaked in perfluorooctyl trichlorosilane, and placed in a conventional desiccator to stand fo...

Embodiment 2

[0025] In this example, commercially available 0.1mol pyrrole monomer and 0.05mol sodium dodecylbenzenesulfonate were added to 1L of dedistilled water, stirred at a constant temperature at 20°C until completely dissolved to form an electrolyte solution, and a three-electrode system was used at 1.4V Carry out potentiostatic polymerization under electric potential, and the reaction time is 20 minutes. Polypyrrole film is obtained on the surface of low-alloy steel working electrode. The prepared polypyrrole is taken out from the electrolyte solution, rinsed repeatedly with distilled water, and placed in a vacuum drying oven at 60°C under vacuum. Drying for 24 hours to obtain polypyrrole / low-alloy steel, soaking polypyrrole / low-alloy steel in perfluorododecyltrichlorosilane and placing it in a desiccator for 36 hours, then impregnating it with perfluoropolyether oil to obtain The final product perfluoropolyether oil / polypyrrole composite material is a conductive polymer-perfluoropo...

Embodiment 3

[0028]In this example, 0.3 mol of pyrrole monomer and 0.1 mol of sodium lauryl sulfate commercially available were added to 1 L of de-distilled water, stirred at a constant temperature at 20°C until completely dissolved to form an electrolyte solution, and the three-electrode system was used at a potential of 1.8V. Potentiostatic polymerization, the reaction time is 10min, the polypyrrole film is obtained on the surface of the low-alloy steel working electrode, the prepared polypyrrole is taken out from the electrolyte solution, washed repeatedly with distilled water, and dried in a vacuum oven at 60°C for 24h to obtain the polypyrrole film. The molecular structure infrared spectrum of pyrrole / low alloy steel and polypyrrole / low alloy steel is as follows Figure 4 shown; then polypyrrole / low-alloy steel was soaked in perfluorooctyltrichlorosilane, and placed in a desiccator for 48 hours and then impregnated with perfluoropolyether oil to obtain the final product conductive poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com