Water-based anticorrosive coating and preparation method thereof

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of the utilization efficiency of shielding materials in polluted environments, the toughness of zinc-rich coatings, and low adhesion, and achieve convenient operation and high technology easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

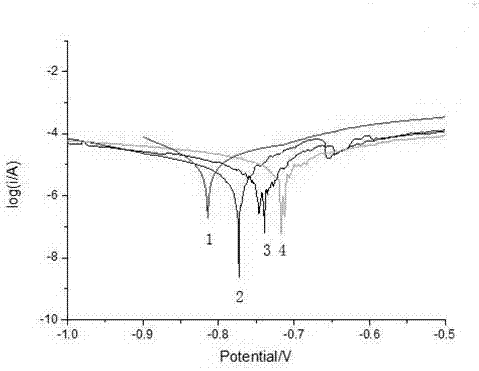

Image

Examples

preparation example Construction

[0076] The embodiments of the present invention provide a water-based anti-corrosion coating and a preparation method thereof. The conductive polymer / fullerene composite modified water-based anti-corrosion coating is prepared by stirring and mixing components A and B uniformly; the component A Including the following components: water-based isocyanate curing agent, zinc powder, defoamer, wetting and dispersing agent, anti-sedimentation thixotropic agent, conductive polymer / fullerene composite material, anti-flash rust agent, leveling agent, adhesion promotion agent, anti-rust pigment.

[0077] Preferably, the curing agent is at least one of water-based isocyanate curing agents BA305, XP2451, and XP 2487. BA305 is a crosslinking agent for water-based coatings. Even under pre-diluted conditions, the coating film is still transparent and bright; XP 2451 and XP 2487 is used as a curing agent component of water-based two-component coatings and sealers, and also as an additive to en...

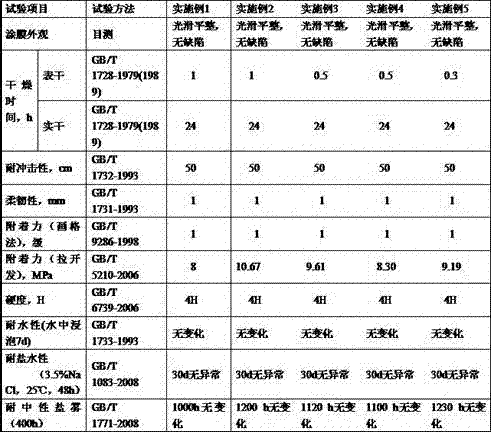

Embodiment 1

[0090] In terms of parts by mass, the raw material formula of component A consists of: 15 parts of BA305, 55 parts of 400 mesh zinc powder, 5 parts of EL-2607, 5 parts of SN-5040, 2 parts of organic bentonite, 2 parts of conductive polymer / fullerene parts, ZT-709 0.5 parts, SN-612 0.5 parts, kh560 3 parts, zinc phosphate 10 parts. The raw material formula of component B is composed of: 6 parts of methyl methacrylate, 20 parts of butyl acrylate, 16 parts of styrene, 15 parts of epoxy resin, 1 part of methacrylic acid, 1 part of acrylamide, and 1.5 parts of hydroxyethyl acrylate , 1.5 parts of emulsifier, 4 parts of initiator, 120 parts of deionized water, 0.4 part of ammonia water.

[0091] Follow the steps below to prepare water-based anti-corrosion coatings

[0092] Step 1. Add fullerene to the hydrochloric acid solution, and carry out ultrasonic dispersion for 1 hour. After the dispersion is uniform, add polyaniline, polythiophene, polypyrrole and its derivative monomers, s...

Embodiment 2

[0101] In terms of parts by mass, the raw material formula of component A consists of: 20 parts of XP2451, 15 parts of 600-mesh zinc powder, 1 part of DF-103, 1 part of SN-5040, 1 part of organic bentonite, 0.5 parts of fumed silica, conductive 2.5 parts of polymer / fullerene composite material, 0.7 parts of ZT-709, 0.8 parts of SN-612, 3.5 parts of kh550, 10 parts of zinc phosphate, 5 parts of iron and titanium powder; component B is made of the following parts by mass: methyl 13 parts of methyl acrylate, 25 parts of butyl acrylate, 12 parts of styrene, 30 parts of epoxy resin, 6 parts of methacrylic acid, 5 parts of acrylamide, 2 parts of hydroxyethyl acrylate, 4 parts of emulsifier, 5 parts of initiator , 130 parts of deionized water, 0.4 part of ammonia water.

[0102] Follow the steps below to prepare water-based anti-corrosion coatings

[0103] Step 1. Add fullerene to hydrochloric acid solution, and carry out ultrasonic dispersion for 30 minutes. After the dispersion is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com