Device and method for repairing concrete structure damaged by salt through two-step process

A concrete structure and concrete technology, applied in the field of electrochemical repair, can solve the problem of low precipitation efficiency of harmful ions, and achieve the effects of improving migration ability, convenient operation and improving precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

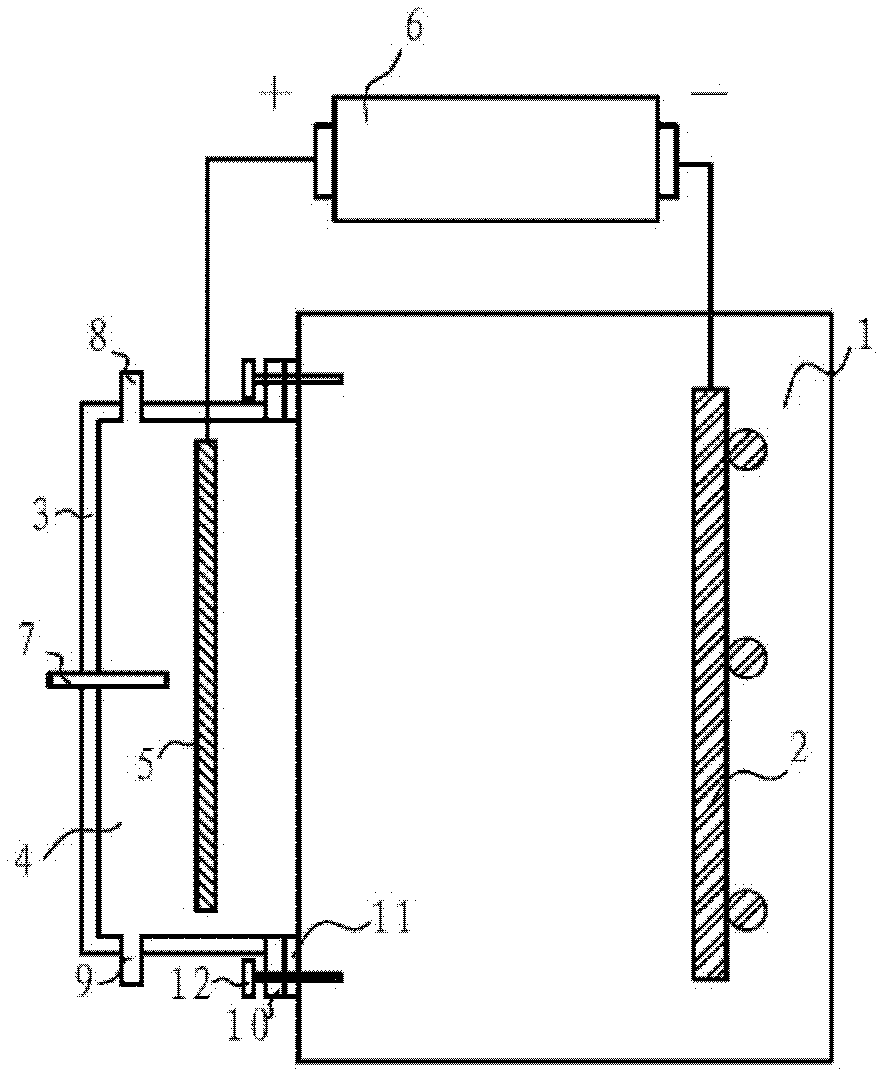

[0026] Such as figure 1 As shown, the device for repairing salt-injured concrete structures in two steps according to the present invention comprises a steel bar in the concrete (1) as a cathode (2), an electrolytic cell (3) in which the notch is sealed and matched with the surface of the concrete (1), and an electrolytic cell (3) located in the electrolytic The electrolyte (4) in the tank (3), the anode (5) immersed in the electrolyte (4), the DC power supply (6) for supplying power to the cathode (2) and the anode (5), and a pH indicator (7), The anode is a stainless steel mesh, the electrolytic cell (3) has an inlet (8) and an outlet (9) of the electrolyte (4), and the probe of the pH indicator (9) runs through the cell wall of the electrolytic cell (3) and is connected with the electrolytic cell (3). Liquid (4) contact, electrolytic cell (3) and concrete (1) surface contact position is provided with water-swelling water-stop bead (10), described water-stop bead (10) and co...

Embodiment 2

[0027] Embodiment 2 two-step method repairs the concrete structure of salt damage

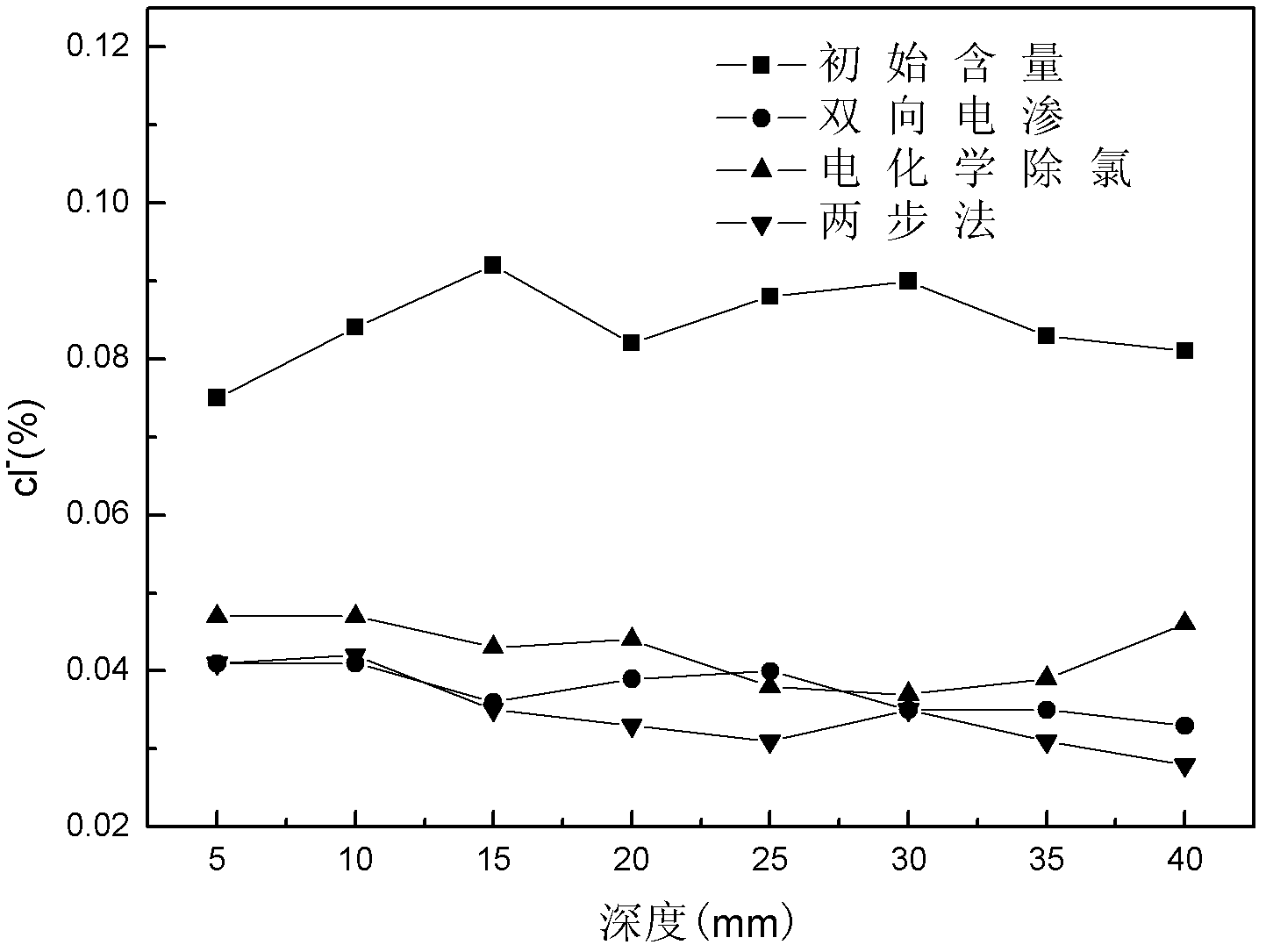

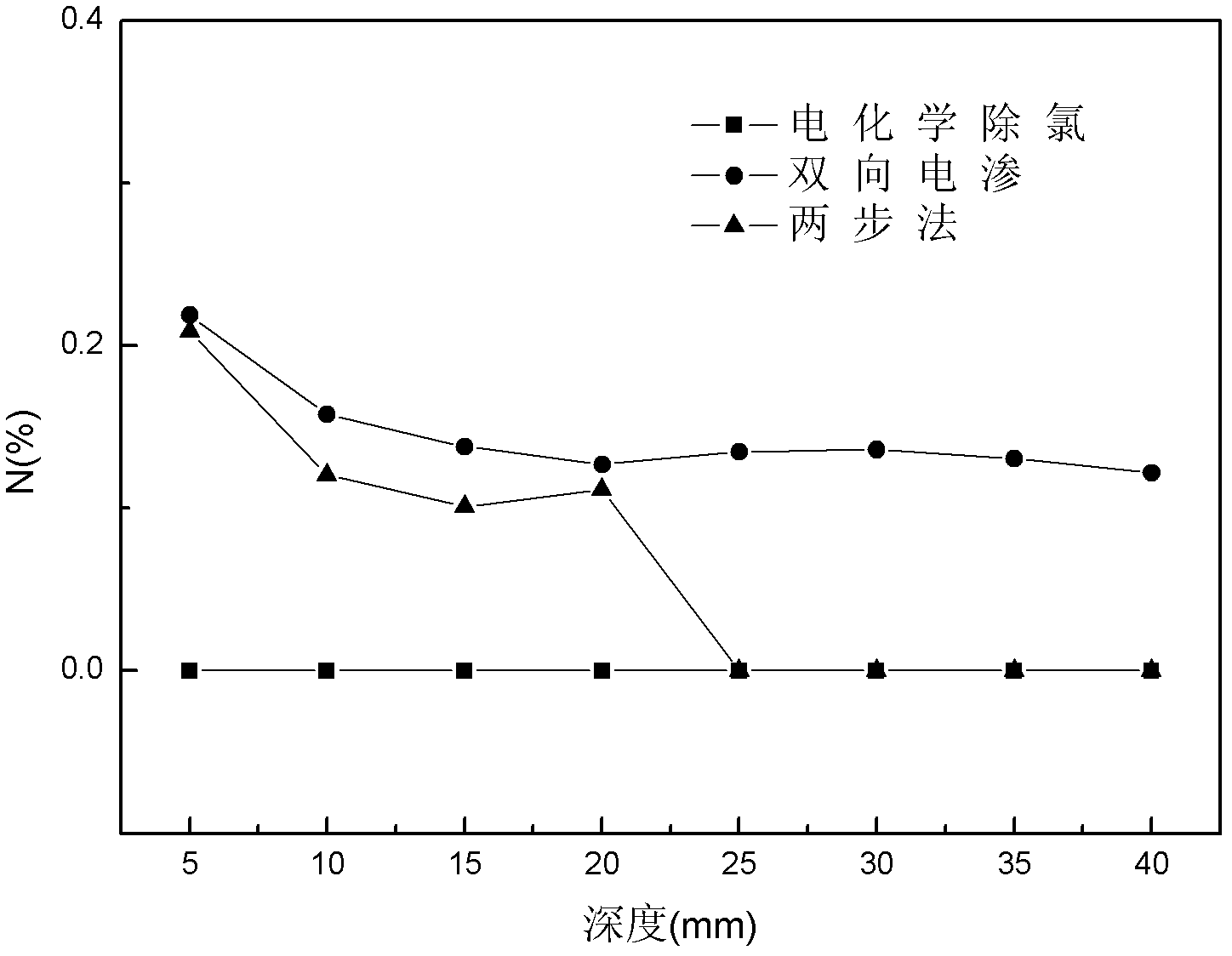

[0028] The mass ratio of each component of the concrete structure is: cement: sand: gravel: water = 1: 1.40: 2.60: 0.49, that is, to configure a cubic meter of fresh concrete, use 210kg of water, 429kg of cement, 600kg of medium sand and 1115kg of particle size 5 ~ 16mm stones, among them, 2% of the cement mass, that is, 8.58kg of sodium chloride is added when the concrete is poured, the water-cement ratio is 0.5, the depth of the protective layer is 40mm, the standard maintenance is 28 days, and it is placed in the room for 5 months Finally, the electrochemical impedance spectrum and weak polarization curves of the steel bars in the concrete specimens before repair were measured with an electrochemical workstation Reference600, and it was found that the steel bars had been corroded. At the same time, along the depth direction of the concrete protective layer, drill holes to take powder, and us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com