Research for Q235 steel argon arc cladding FeCoCrMoCBY alloy coating

A technology of cladding and iron-based alloys, which is applied in the coating process and coating of metal materials, and can solve the problems of safety accident economy, reduction of application fields, and limitation of the use range of steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Experimental materials

[0047] 1. Base material

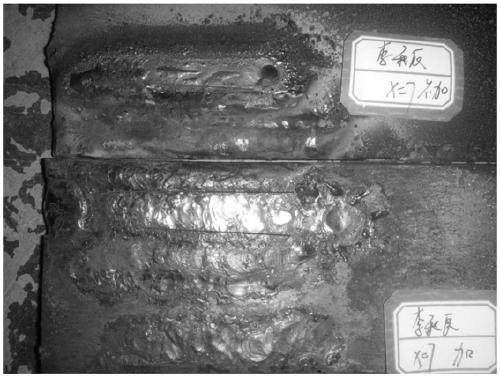

[0048] The base material is rolled Q235 steel. Due to the storage time and storage environment, there are rust, stains and grease on the steel surface. These factors will have an adverse effect on the subsequent surface cladding process. Pretreatment of the substrate surface. First use an angle grinder to remove the rust stains on the surface of Q235 steel and polish the surface brightly, then use absorbent cotton dipped in absolute ethanol to wipe and clean the surface, then use a hair dryer to dry the ethanol and place it in a drying box spare.

[0049] 2. Preparation of cladding coating

[0050] (1) Alloy coating material selection

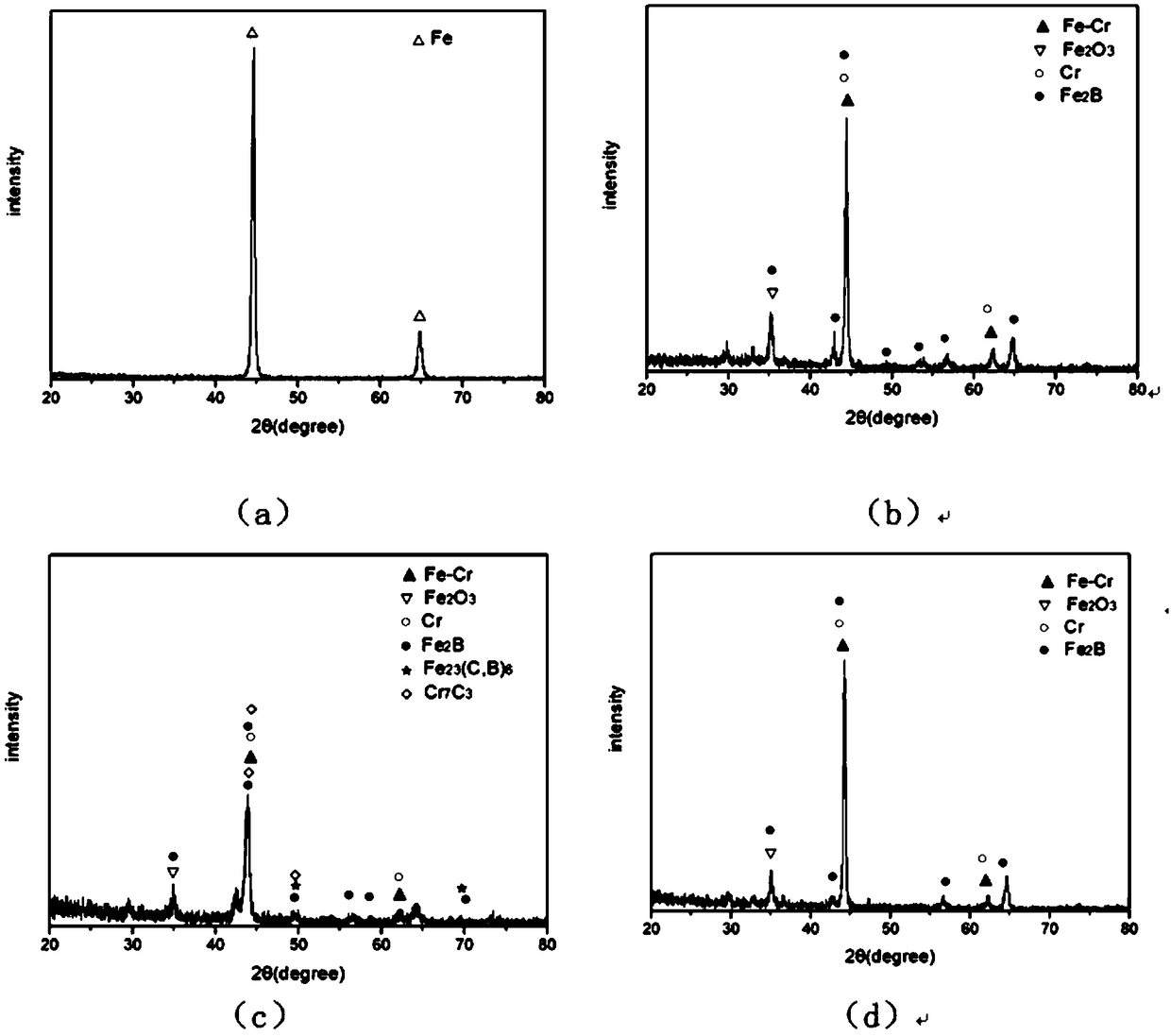

[0051] Seven alloys of Fe, Co, Cr, Mo, C, B, and Y are selected as the prepared materials, and the molar ratio of each element is 48-x:x:15:14:15:6:2, that is, Fe 48-x co x Cr 15 Mo 14 C 15 B 6 Y 2 (x=0,7,9). Wherein the total mass of the powders of different components i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average vickers hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com