Abrasion-resistant and corrosion-resistant MnNbTaTiV high-entropy alloy material and preparation method thereof

A high-entropy alloy and corrosion-resistant technology, which is applied in the field of MnNbTaTiV high-entropy alloy and its preparation, can solve the problems of limiting the diversification of alloy types and other problems, and achieve the effects of low cost, uniform alloy structure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preparation method and process performance of the present invention are illustrated by specific specific examples below, and those skilled in the art can fully understand the advantages and functions of the present invention from the contents disclosed in this specification.

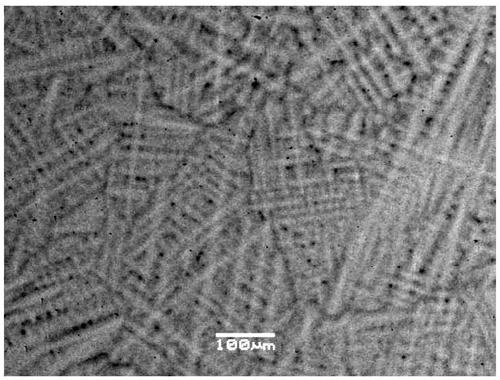

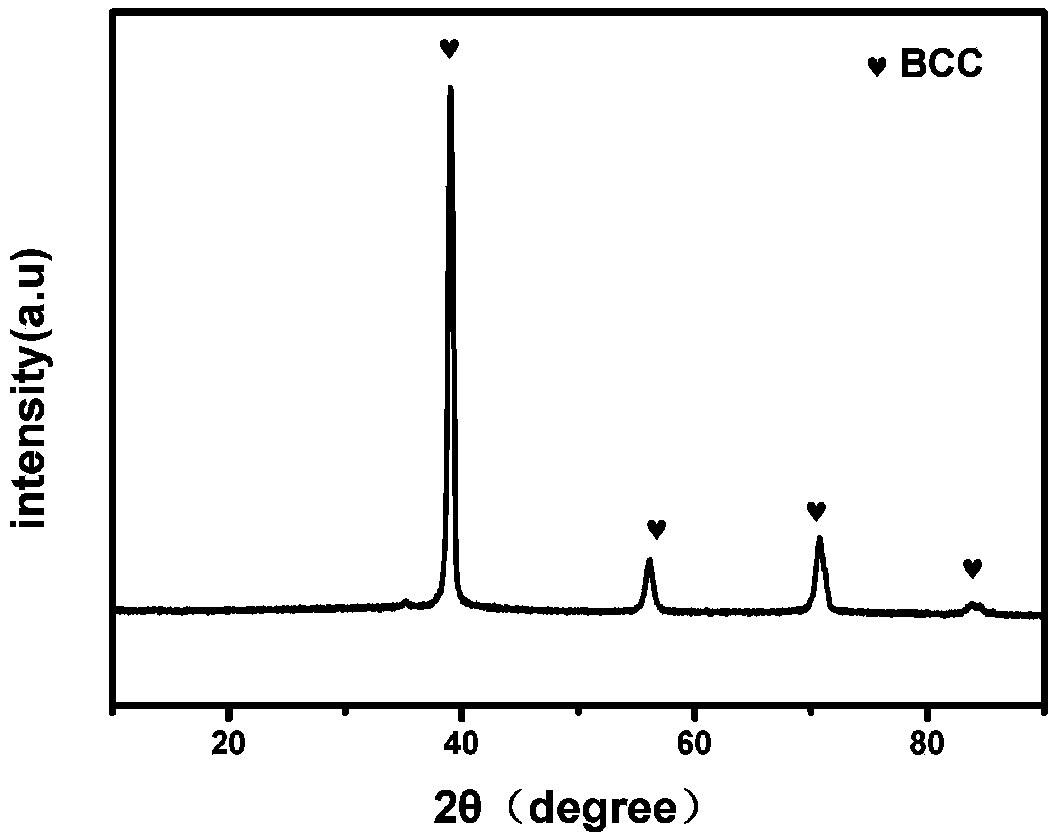

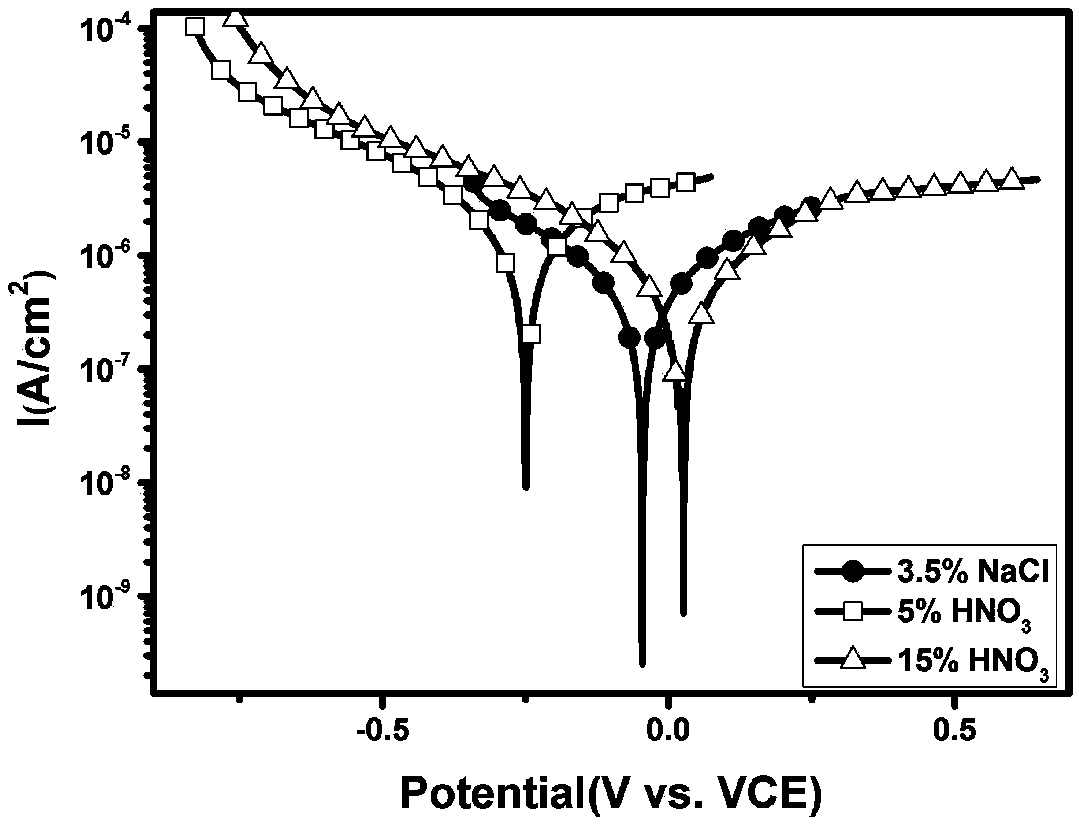

[0023] 1. MnNbTaTiV high entropy alloy composition design

[0024] This embodiment is a MnNbTaTiV high-entropy alloy composed of five elements: Mn, Nb, Ta, Ti, and V, wherein Mn:Nb:Ta:Ti:V is in an equimolar ratio.

[0025] 2. Preparation of MnNbTaTiV high entropy alloy

[0026] Concrete preparation process is as follows:

[0027] 1) raw material preparation: the alloy smelting raw material that the present invention adopts is high-purity (purity is more than 99.5%) Mn, Nb, Ta, Ti, V metal powder;

[0028] 2) Weighing and mixing powder: Carry out accurate weighing and mixing ratio according to the molar ratio, and mix the weighed powder materials together, and use a V-type powder mixing mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com