Micro-arc oxidation self-assembled chemical nickel-plated coating on surface of magnesium alloy and preparation method of micro-arc oxidation self-assembled chemical nickel-plated coating

A technology of electroless nickel plating and micro-arc oxidation, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve problems such as long-term protection effect concerns, achieve low corrosion current density, and improve corrosion resistance Sexuality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

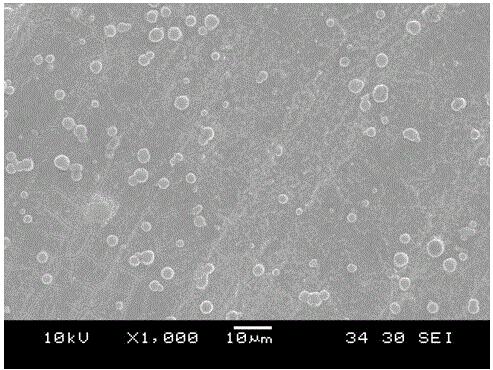

Image

Examples

Embodiment

[0020] (1) Pretreatment

[0021] Grind AZ91 magnesium alloy step by step with 600# and 1000# water-resistant abrasive paper, wash with water, and then degrease in alkaline degreasing solution at 60°C for 10 minutes, then wash the surface of the sample with hot water and cold water respectively, and then Ultrasonic cleaning in acetone for 10 minutes, cleaning with deionized water for 3 times, and drying with cold wind for later use; the formula of the alkaline degreasing liquid is: sodium phosphate 40g / L, sodium hydroxide 10g / L, sodium silicate 32g / L.

[0022] (2) Micro-arc oxidation

[0023] Put the AZ91 magnesium alloy treated in step (1) into the micro-arc oxidation electrolyte as the anode for micro-arc oxidation treatment, the cathode is stainless steel, and adopt the pulse micro-arc oxidation method. The time is 20 minutes, the pulse frequency is 50 Hz, and the duty cycle is 30%; the formula of the micro-arc oxidation electrolyte is: sodium silicate 5 g / L, sodium fluorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com