Method for improving corrosion resistance of sintered neodymium iron boron magnet

A neodymium-iron-boron, corrosion-resistant technology, used in inductor/transformer/magnet manufacturing, coating, laser welding equipment, etc. Intrinsic corrosion resistance, simple process, and the effect of improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) The sintered NdFeB magnet Nd 9 PR 3 Fe 80 co 2 B 5.5 Cu 0.5 Grinding, polishing, cleaning and drying pretreatment on the surface to be processed;

[0024] 2) Clamp the pretreated sintered NdFeB magnet on the workbench;

[0025] 3) Under vacuum, irradiate the surface of the sintered NdFeB magnet to be processed with continuous laser to melt the grain boundary phase to form a micro-melt pool. The laser power is 500W, the scanning speed is 5mm / s, the spot diameter is 2mm, and the overlap rate is 20%;

[0026] 4) Send 20nm metal Al nanopowder into the grain boundary micro-melting pool through the powder feeding device, so that it can be microalloyed with the grain boundary phase;

[0027] 5) The unalloyed nanopowder is cleaned up to obtain a sintered NdFeB magnet modified by surface grain boundary selective microalloying.

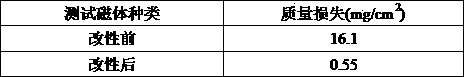

[0028] The corrosion resistance of sintered NdFeB magnets before and after surface modification was tested by autoclave experiment (5-10psig, ...

Embodiment 2

[0031] 1) The sintered NdFeB magnet Nd 13 PR 3 Dy 2 Fe 73 B 8 Al 0.5 Ga 0.5Grinding, polishing, cleaning and drying pretreatment on the surface to be processed;

[0032] 2) Clamp the pretreated sintered NdFeB magnet on the workbench;

[0033] 3) Under the protection of argon gas, the surface to be processed of the sintered NdFeB magnet is irradiated with pulsed laser until the grain boundary phase is melted to form a micro molten pool, and the laser power density is 1MW / cm 2 , pulse width 100ns, overlap rate 80%;

[0034] 4) Send 100nm compound SiC nanopowder into the grain boundary micro-melting pool through the powder feeding device, so that it can be microalloyed with the grain boundary phase;

[0035] 5) The unalloyed nanopowder is cleaned up to obtain a sintered NdFeB magnet modified by surface grain boundary selective microalloying.

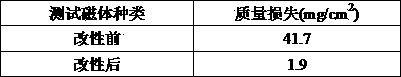

[0036] The corrosion resistance of sintered NdFeB magnets before and after surface modification was tested by autoclave experimen...

Embodiment 3

[0039] 1) The sintered NdFeB magnet Nd 14 Tb 0.1 Fe 79.8 B 6 Zr 0.1 Grinding, polishing, cleaning and drying pretreatment on the surface to be processed;

[0040] 2) Clamp the pretreated sintered NdFeB magnet on the workbench;

[0041] 3) Under the protection of helium, the surface of the sintered NdFeB magnet to be processed is irradiated with continuous laser to melt the grain boundary phase to form a micro-melt pool. The laser power is 100W, the scanning speed is 20mm / s, the spot diameter is 0.5mm, and the overlap rate is 80 %;

[0042] 4) Send the mixed powder of 60nm metal Cu and 100nm metal Co nanopowder with a volume ratio of 2:1 into the grain boundary micro-melting pool through the powder feeding device, so that it can be microalloyed with the grain boundary phase;

[0043] 5) The unalloyed nanopowder is cleaned up to obtain a sintered NdFeB magnet modified by surface grain boundary selective microalloying.

[0044] The corrosion resistance of sintered NdFeB ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com