A kind of NdFeB magnet preparation method and non-breakable NdFeB magnet

A technology of NdFeB and magnets, which is applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as internal improvement methods and insufficient demand, and limited protection, so as to speed up research and development efficiency and product updates , Magnetic properties have little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] [A preparation method of NdFeB magnet]

[0038] A kind of preparation method of neodymium iron boron magnet, comprises the following steps:

[0039] S1: The NdFeB cast pieces are subjected to hydrogen crushing, disproportionation reaction and jet milling to obtain NdFeB fine powder. The NdFeB cast pieces are obtained from commercially available or self-designed ingredients and added rare earth alloys, and the alloys are smelted , obtained from quick-setting cast sheets, and the Al content in the NdFeB cast sheets is less than 0.1wt%;

[0040] S2: Sieve the NdFeB fine powder with a particle size of 3-4μm from S1, and the Al powder with a particle size of 500-600nm in proportion to the mass ratio of NdFeB fine powder: Al powder (96.5:3.5)~(95.4:4.6 ) mixed, mixed under an inert atmosphere, and mixed uniformly to obtain NdFeB raw material powder;

[0041] S3: Orientation forming of NdFeB raw material powder in a magnetic field to obtain a rough NdFeB magnet;

[0042] S4: ...

Embodiment 1~6

[0049] A NdFeB magnet was prepared according to the above preparation method to prepare NdFeB magnets to obtain the NdFeB magnets of Examples 1-6, wherein the specific parameters of Examples 1-6 are shown in Table 1.

[0050]

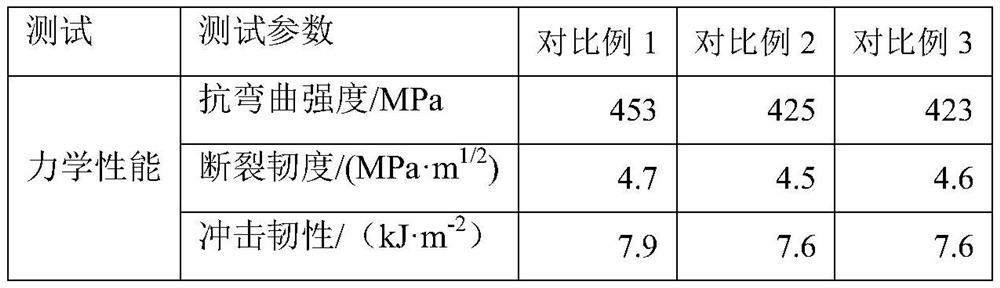

[0051] The NdFeB magnets prepared in Examples 1-6 were tested for bending strength, fracture toughness, impact toughness, and magnetic properties, and the test results are shown in Table 2 below.

[0052] [Bending strength test]

[0053] The test is carried out according to the flexural strength test method recorded in "GB / T 31967.2-2015 Test Method for Physical Properties of Rare Earth Permanent Magnet Materials Part 2: Determination of Flexural Strength and Fracture Toughness".

[0054] [Fracture Toughness Test]

[0055] Test according to the fracture toughness test method recorded in "GB / T 31967.2-2015 Physical Properties of Rare Earth Permanent Magnet Materials Part 2: Determination of Flexural Strength and Fracture Toughness".

[0056] [Impact...

Embodiment 7

[0075] A kind of neodymium iron boron magnet, based on the basis of embodiment 4, its difference is to adjust the neodymium iron boron formula, remove Dy, Tb, Sb element material addition, the element detection result in the obtained neodymium iron boron sintered magnet is Nd: 28wt%; Dy: 0wt%; Tb: 0wt%; B: 1.3wt%; Al: 4.3wt%; Co: 0.8wt%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com