Protective and decorative yellow ceramic layer on magnesium alloy surface and preparation method thereof

A technology of ceramic layer and magnesium alloy, which is applied in the field of both protective and functional coatings on metal surfaces, can solve the problems of monotonous micro-arc oxidation coating color, unstable and safety hazards in the preparation process of yellow micro-arc oxidation ceramic layers, etc., and achieve enhanced Good protection performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

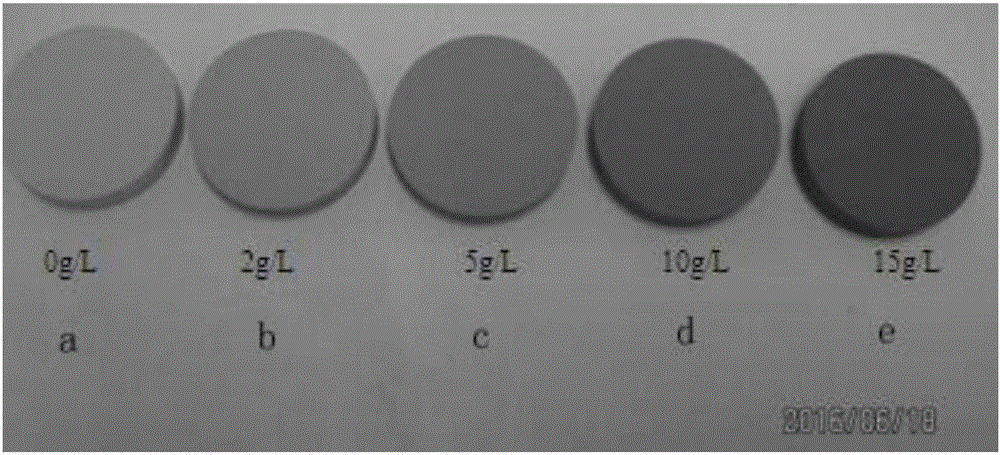

Embodiment 1

[0032] In this embodiment, the surface of the magnesium alloy is a light yellow micro-arc oxidation ceramic layer, that is, the micro-arc oxidation ceramic layer is prepared by adding a small amount of sodium stannate electrolyte, so that the surface layer of the magnesium alloy substrate is formed in situ. Magnesium oxide porous membrane, the thickness of the ceramic layer is 10 μm.

[0033] The preparation method of the yellow micro-arc oxidation ceramic layer on the surface of the magnesium alloy comprises the following steps:

[0034] Step 1: The wire-cut magnesium alloy samples are firstly subjected to degreasing and degreasing processes, then ground with different water sandpapers, and then washed with water after polishing to prepare for micro-arc oxidation treatment.

[0035] Step 2: Select chemical reagents according to the matching principle of magnesium alloy micro-arc oxidation electrolyte, prepare stannate-based micro-arc oxidation electrolyte, wherein the concent...

Embodiment 2

[0039] In this example, the surface of the magnesium alloy is a yellow micro-arc oxidation ceramic layer, that is, the micro-arc oxidation ceramic layer is prepared by adding a relatively large amount of sodium stannate electrolyte, so that the surface layer of the magnesium alloy substrate is formed in situ and doped with a relatively large amount of Sn elements. MgO porous membrane, the thickness of the ceramic layer is 15 μm.

[0040] The preparation method of the yellow micro-arc oxidation ceramic layer on the surface of the magnesium alloy comprises the following steps:

[0041] Step 1: The wire-cut magnesium alloy samples are firstly subjected to degreasing and degreasing processes, then ground with different water sandpapers, and then washed with water after polishing to prepare for micro-arc oxidation treatment.

[0042] Step 2: Select chemical reagents according to the matching principle of magnesium alloy micro-arc oxidation electrolyte, prepare stannate-based micro-...

Embodiment 3

[0046] In this embodiment, the surface of the magnesium alloy is a deep yellow micro-arc oxidation ceramic layer, that is, the micro-arc oxidation ceramic layer is prepared in the electrolyte of adding more sodium stannate, so that the surface layer of the magnesium alloy matrix is formed in situ. Magnesium oxide porous membrane of Sn element, the thickness of the ceramic layer is 20 μm.

[0047] The preparation method of the yellow micro-arc oxidation ceramic layer on the surface of the magnesium alloy comprises the following steps:

[0048] Step 1: The wire-cut magnesium alloy samples are firstly subjected to degreasing and degreasing processes, then ground with different water sandpapers, and then washed with water after polishing to prepare for micro-arc oxidation treatment.

[0049] Step 2: Select chemical reagents according to the matching principle of magnesium alloy micro-arc oxidation electrolyte, prepare stannate-based micro-arc oxidation electrolyte, wherein the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com