Preparing method for graphene oxide composite coating on surface of magnesium alloy

A technology of graphene compounding and surface oxidation, applied in the direction of coating, electrolytic coating, etc., to achieve the effect of simple operation, low corrosion current density, and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

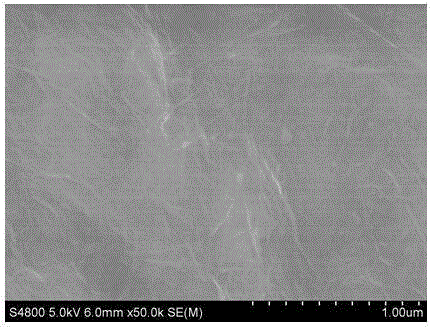

Image

Examples

Embodiment

[0015] (1) Pretreatment of magnesium alloy

[0016] The AZ91 magnesium alloy was successively ground, polished, and washed with 600# and 1200# water-resistant abrasive paper, and then degreased in alkaline degreasing solution at 60°C for 1 minute, and then cleaned the surface of the sample with hot water and cold water respectively. Then ultrasonic cleaning in absolute ethanol for 10 minutes, ultrasonic cleaning with deionized water for 3 times, and cold air drying for subsequent use; the formula of the alkaline degreasing liquid is: sodium phosphate 20g / L, sodium hydroxide 20g / L, sodium carbonate 30g / L.

[0017] (2) Preparation of graphene oxide

[0018] Graphite oxide is prepared by the improved Hummers method. First cool 120ml of concentrated sulfuric acid in an ice-water bath. Under stirring, slowly add 5g of graphite powder in batches. After the reactants are completely mixed, the system is black; then slowly add 15g of high manganese in batches. Potassium acid, the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com