Nitrite-free compound type steel bar corrosion inhibitor

A technology of steel bar rust inhibitor and nitrite, applied in the field of steel bar rust inhibitor, can solve the problems of application limitation, ineffectiveness, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

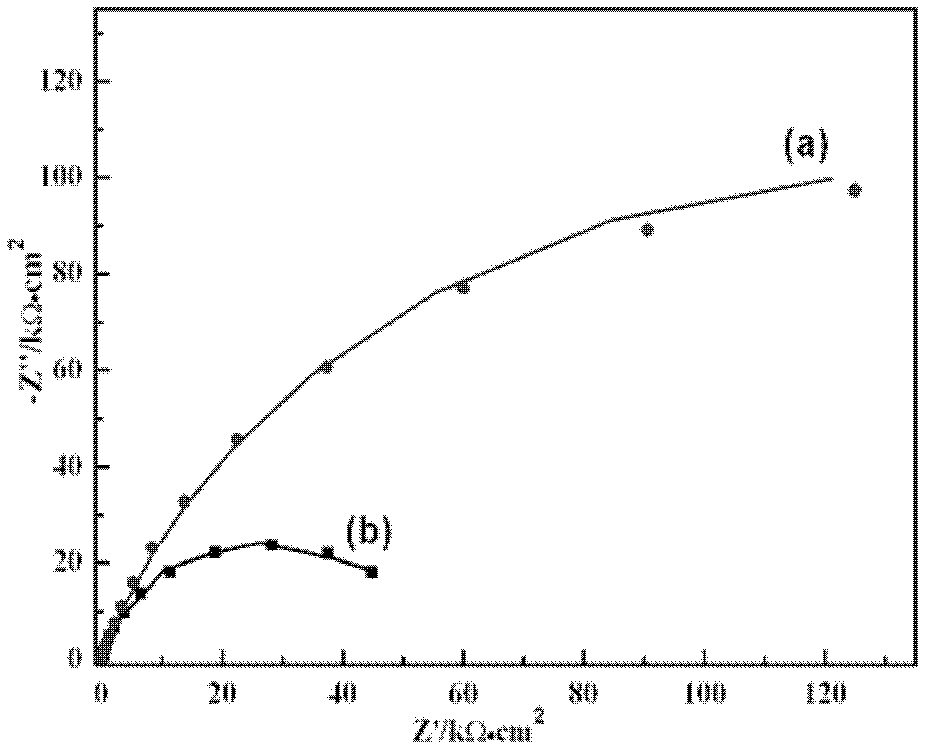

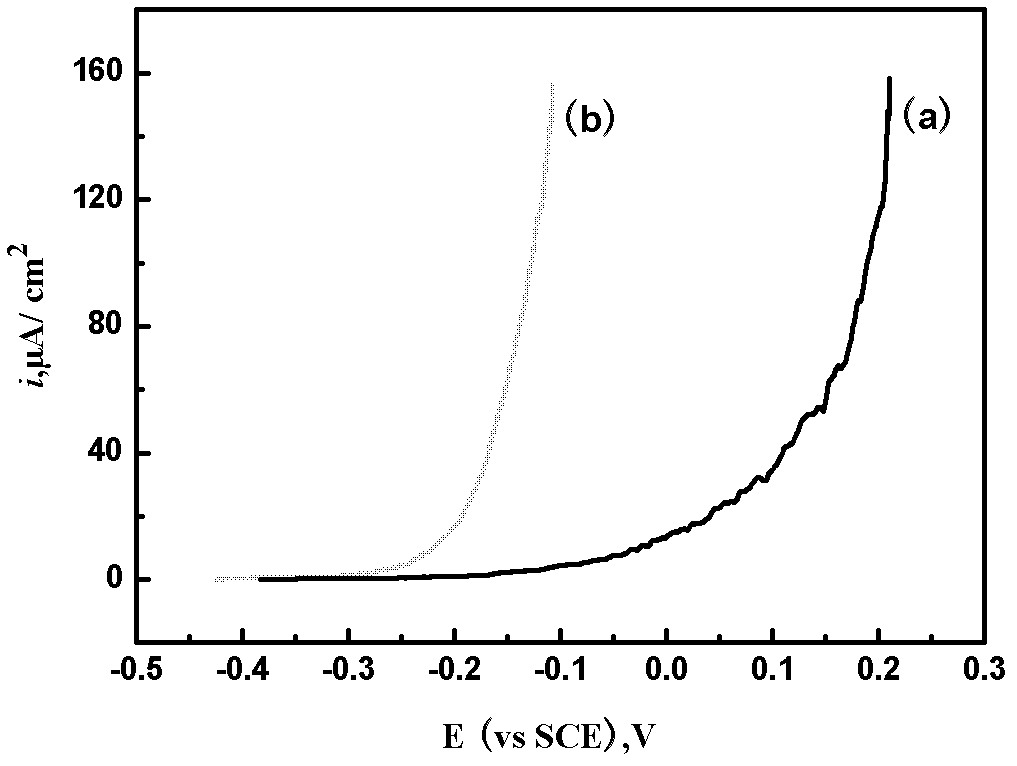

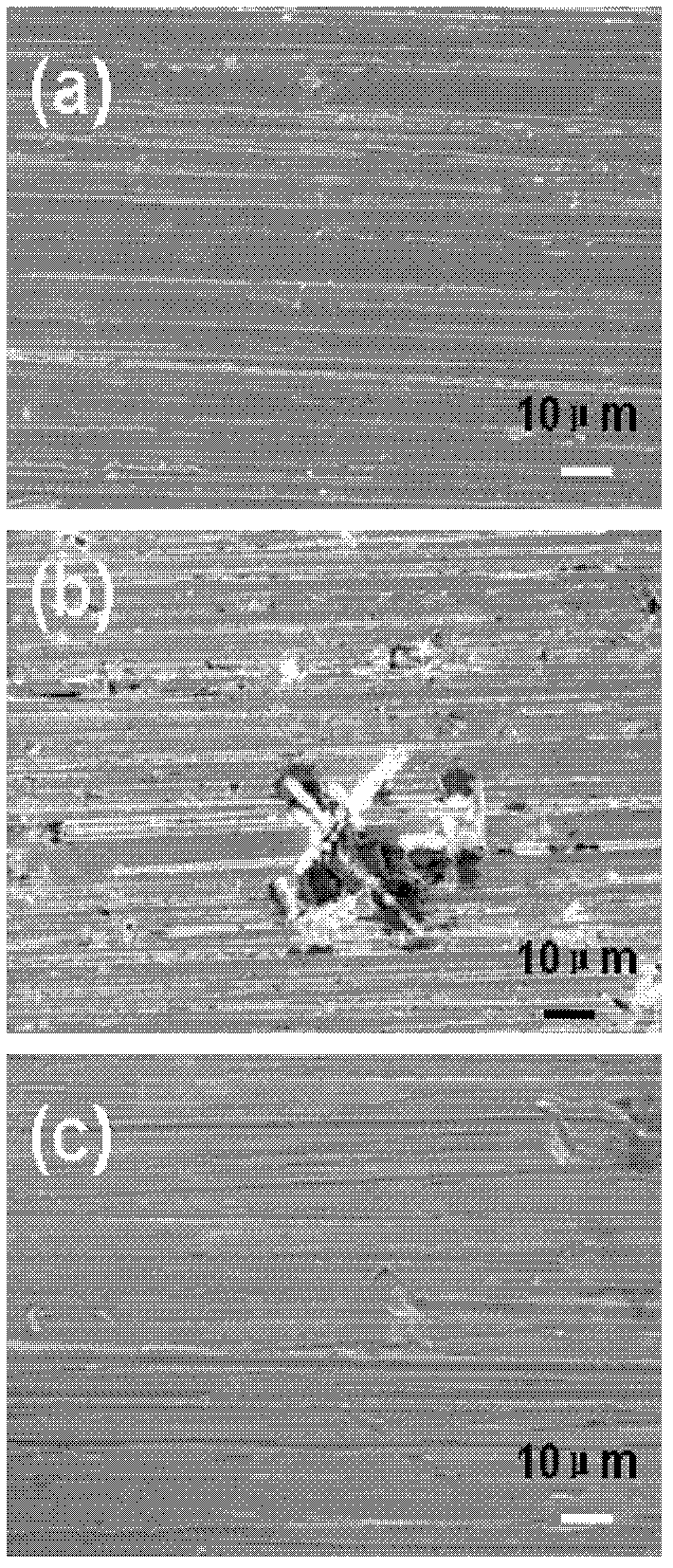

[0024] According to the above technical scheme, the R235 light round steel bar used in construction is used as the test material. Before testing in the simulated liquid, it is processed into a cylindrical sample with a diameter of 11.2 mm and a height of 4 mm. After the sandpaper is polished step by step to remove the surface scale, one section is used to weld the copper wire. The solder joints and the side surface are encapsulated in the plastic ferrule with epoxy resin, and the other section is used as the working surface. The working area is about 1cm 2 . The SEM test electrode is a R235 light round steel bar after removing the surface scale, and then processing it into a cylindrical sample with a diameter of 5.0mm and a height of 2.0mm. Before the observation, the steel bar electrodes were polished step by step with No.400-1200 water abrasive paper, rinsed with deionized water, ultrasonically cleaned in ethanol for 10 minutes, and finally stored in a desiccator for later u...

Embodiment 2

[0036] According to the above technical scheme, the R235 light round steel bar used in construction is used as the test material. Before testing in the simulated liquid, it is processed into a cylindrical sample with a diameter of 11.2 mm and a height of 4 mm. After the sandpaper is polished step by step to remove the surface scale, one section is used to weld the copper wire. The solder joints and the side surface are encapsulated in the plastic ferrule with epoxy resin, and the other section is used as the working surface. The working area is about 1cm 2 . The SEM test electrode is R235 light round steel bar after removing the surface scale, and then processing it into a cylindrical sample with a diameter of 5.0mm and a height of 2.0mm. Before the observation, the steel bar electrodes were polished step by step with No.400-1200 water abrasive paper, rinsed with deionized water, ultrasonically cleaned in ethanol for 10 minutes, and finally stored in a desiccator for later use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com