Rare-earth magnesium alloy and preparation method thereof

A rare earth magnesium and alloy technology, which is applied in the field of magnesium-based alloys, can solve the problems that the comprehensive performance is difficult to meet the needs, and achieve the effects of improving solid solubility, wide source of raw materials, and reducing energy consumption and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

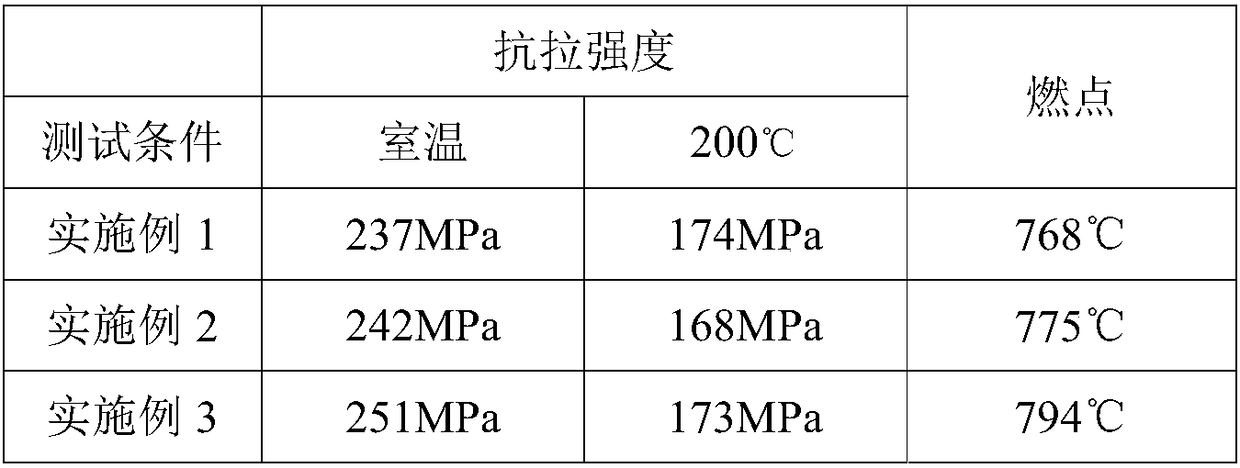

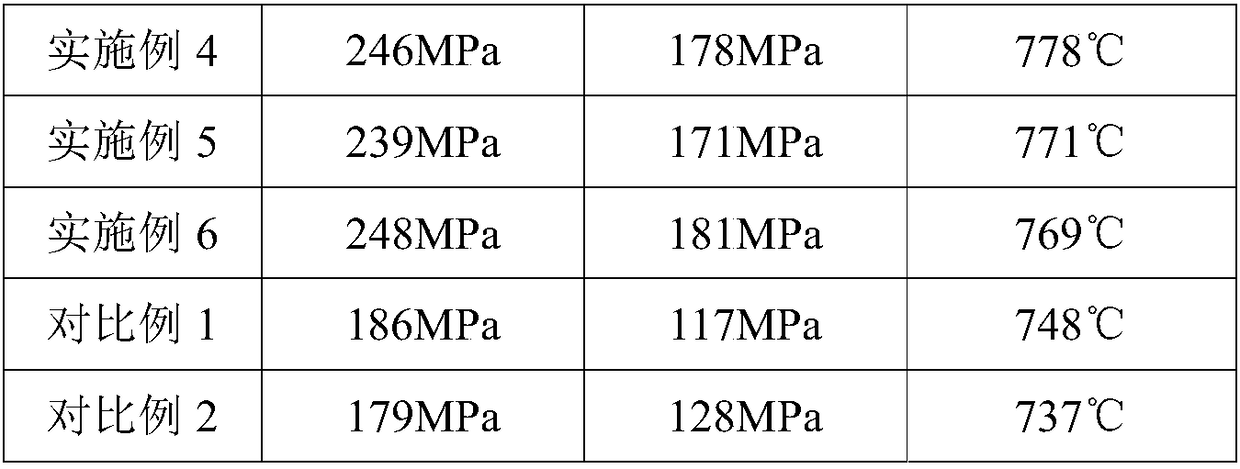

Examples

Embodiment 1

[0027] The rare earth magnesium alloy of this embodiment is composed of the following components in mass percentage: Al 5.0%, Zn 0.9%, Mn 0.2%, Nb 0.25%, Sm 0.55%, Y 0.35%, the balance is Mg and unavoidable Impurities: the total mass of Fe, Cu and Ni in the impurities accounts for less than 0.2% of the mass percentage of the rare earth magnesium alloy.

[0028] The preparation method of the rare earth magnesium alloy of the present embodiment comprises the following steps:

[0029] 1) Weigh the required amount of raw materials according to the ratio, then preheat each raw material to 200°C, and then 2 +SF 6 Under the protection of mixed gas, put pure magnesium, pure aluminum, pure zinc, and pure manganese into the corundum crucible for melting, and obtain the alloy melt after all the components are melted;

[0030] 2) Adjust the temperature of the alloy melt to 700°C, then add the magnesium-rare earth master alloy and aluminum-niobium alloy that have been preheated to 200°C,...

Embodiment 2

[0033] The rare earth magnesium alloy of this embodiment is composed of the following components in mass percentage: Al 5.5%, Zn 0.8%, Mn 0.2%, Nb 0.3%, Sm 0.5%, Y 0.35%, the balance is Mg and unavoidable Impurities, the total mass of Fe, Cu and Ni in the impurities accounts for less than 0.2% of the mass percentage of the rare earth magnesium alloy.

[0034] The preparation method of the rare earth magnesium alloy of this embodiment is completely the same as that of Embodiment 1 except for the amount of raw materials used.

Embodiment 3

[0036] The rare earth magnesium alloy of this embodiment is composed of the following components by mass percentage: Al 5.5%, Zn 0.85%, Mn 0.3%, Nb 0.28%, Sm 0.45%, Y 0.3%, and the balance is Mg and unavoidable Impurities, the total mass of Fe, Cu and Ni in the impurities accounts for less than 0.2% of the mass percentage of the rare earth magnesium alloy.

[0037] The preparation method of the rare earth magnesium alloy of this embodiment is completely the same as that of Embodiment 1 except for the amount of raw materials used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com