Preparation method of graphene/titanium dioxide transparent anticorrosive coating

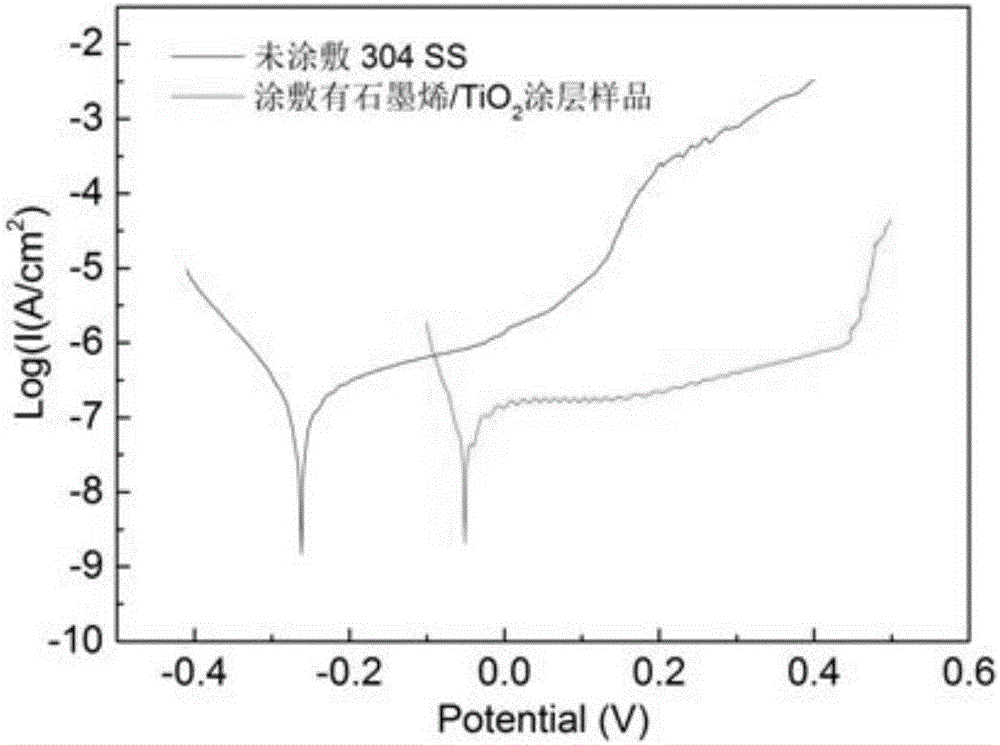

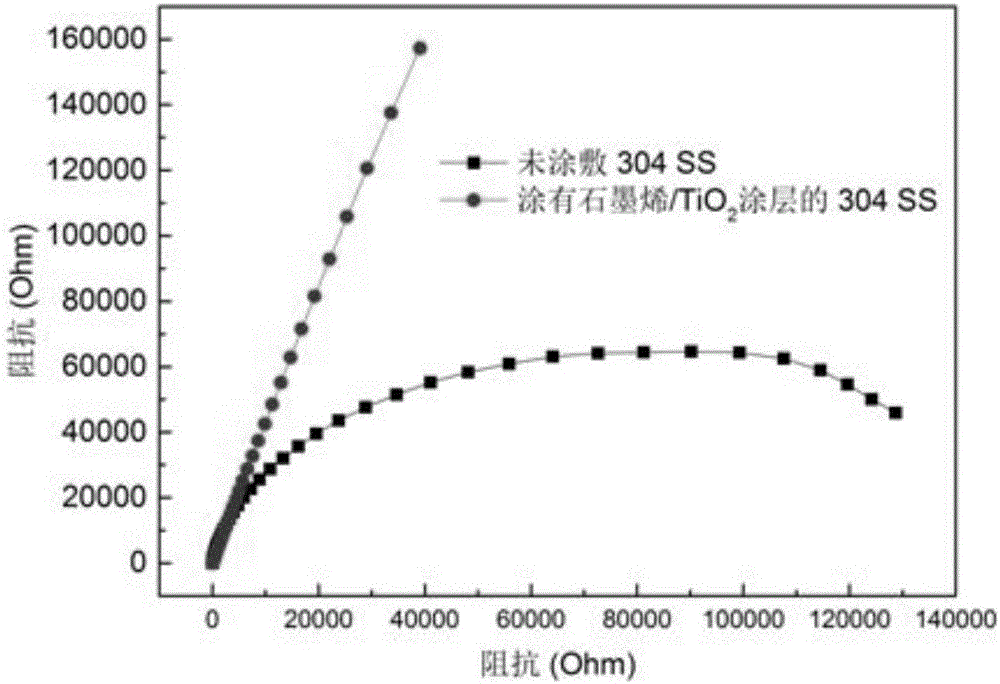

A titanium dioxide and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, devices for coating liquids on the surface, etc., can solve the problems of low precision and opaque coating layers, and achieve easy control of thickness and uniform anti-corrosion coating. , Improve the effect of photogenerated current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of graphene oxide / titanium oxide dispersion:

[0029] Preparation of component A graphene oxide solution: Weigh 0.01 g of freeze-dried graphene oxide, add 1 L of distilled water, and ultrasonically disperse for 1 hour.

[0030] B component TiO 2 Preparation: Take 10% TiO 2 Add 1L of distilled water to 100 ml of sol solution, and ultrasonically disperse for 1 hour.

[0031] (2) Pretreatment of 304 stainless steel samples: Clean the surface of the stainless steel plate with deionized water for 15 minutes, and dry it with a fan.

[0032] (3) Coating of graphene oxide / titanium oxide coating:

[0033] Use the method of suspension coating: preheat the surface of the sample with a hot air blower for 2 minutes, apply component A by means of suspension coating (brush coating), and dry it, then apply component B and dry it.

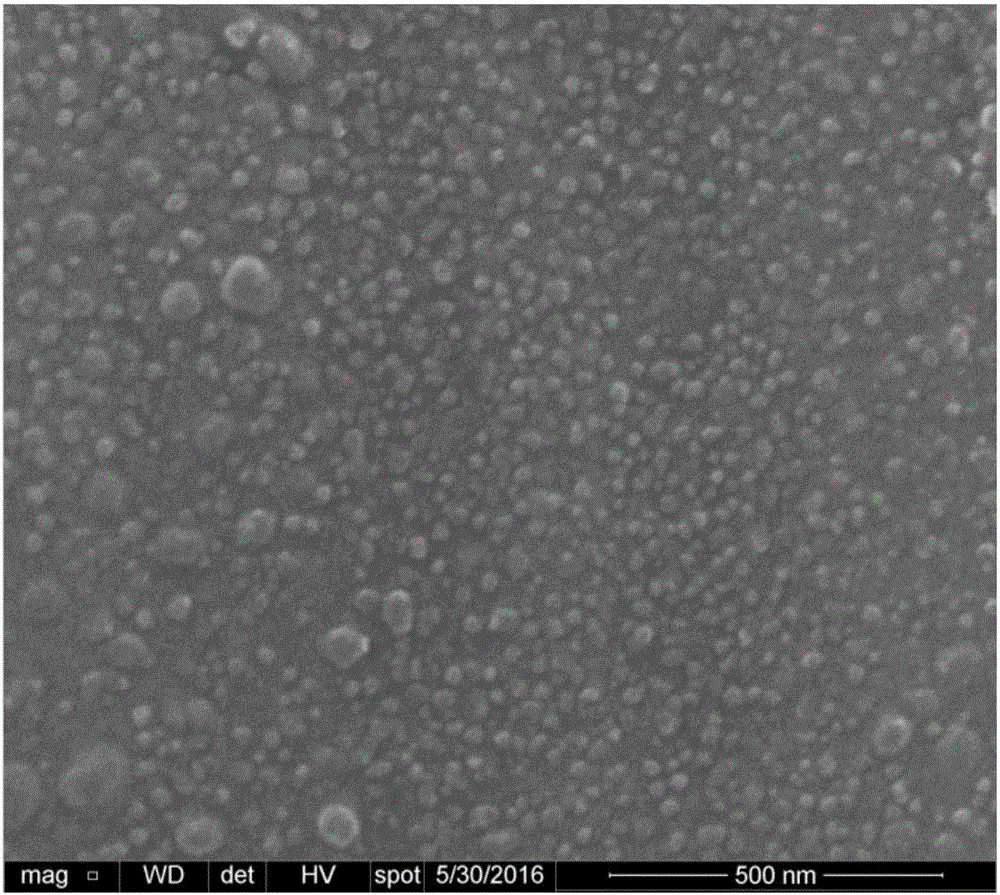

[0034] (4) After coating, the sample is in N 2 Annealed at 200°C for 120 minutes under protective atmosphere. A graphene / titanium oxid...

Embodiment 2

[0037] (1) Preparation of graphene oxide / titanium oxide dispersion:

[0038] Preparation of component A graphene oxide solution: Weigh 0.1 g of freeze-dried graphene oxide, add 1 L of distilled water, and ultrasonically disperse for 1 hour.

[0039] B component TiO 2 Preparation: Take 10% TiO 2 Add 1 L of distilled water to 500 ml of sol solution, and ultrasonically disperse for 1 hour.

[0040] (2) Pretreatment of stainless steel samples: the surface of the stainless steel plate was cleaned with deionized water for 15 min, and dried with a blower.

[0041] (3) Coating of graphene oxide / titanium oxide coating:

[0042] Apply by brush: Preheat the surface of the sample with a hot air blower for 2 minutes, apply component A and dry it, then apply component B and dry it. Repeat the above operation 4 times.

[0043] (4) After coating, the sample is in N 2 Anneal at 500°C for 20 minutes under protective atmosphere. A graphene / titanium oxide anti-corrosion coating with good t...

Embodiment 3

[0046] (1) Preparation of graphene oxide / titanium oxide dispersion:

[0047] Preparation of component A graphene oxide solution: Weigh 0.05 g of freeze-dried graphene oxide, add 1 L of distilled water, and disperse ultrasonically for 1 hour.

[0048] B component TiO 2 Preparation: Take 10% TiO 2 Add 1L of distilled water to 300 ml of sol solution, and ultrasonically disperse for 1 hour.

[0049] A+B mixed liquid: mix according to the volume ratio of A component: B component 1:1.

[0050] (2) Pretreatment of stainless steel samples: Clean the surface of the stainless steel plate with deionized water for 15 minutes, and dry it with a fan.

[0051] (3) Coating of graphene oxide / titanium oxide coating:

[0052] Ultrasonic atomization spraying method is adopted: 500 ml of A+B coating solution is put into an ultrasonic atomization sprayer, sprayed for 2 minutes, and dried. Repeat the above operation 2 times.

[0053] (4) After coating, the sample is in N 2 Anneal at 100°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com