Anti-corrosion rare earth magnesium alloy and preparation method thereof

A rare earth intermediate alloy and rare earth magnesium technology, which is applied in the field of magnesium alloy materials, can solve the problems that tensile strength and comprehensive properties are difficult to meet requirements, and achieve the effects of improving solid solubility, improving mechanical properties, and reducing corrosion current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

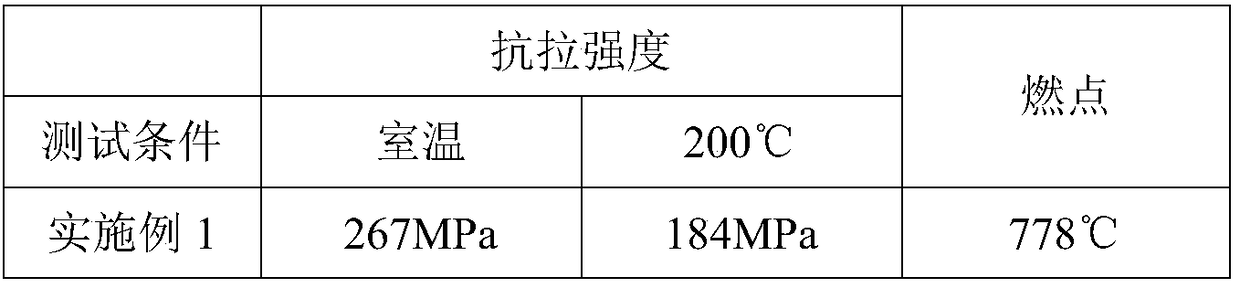

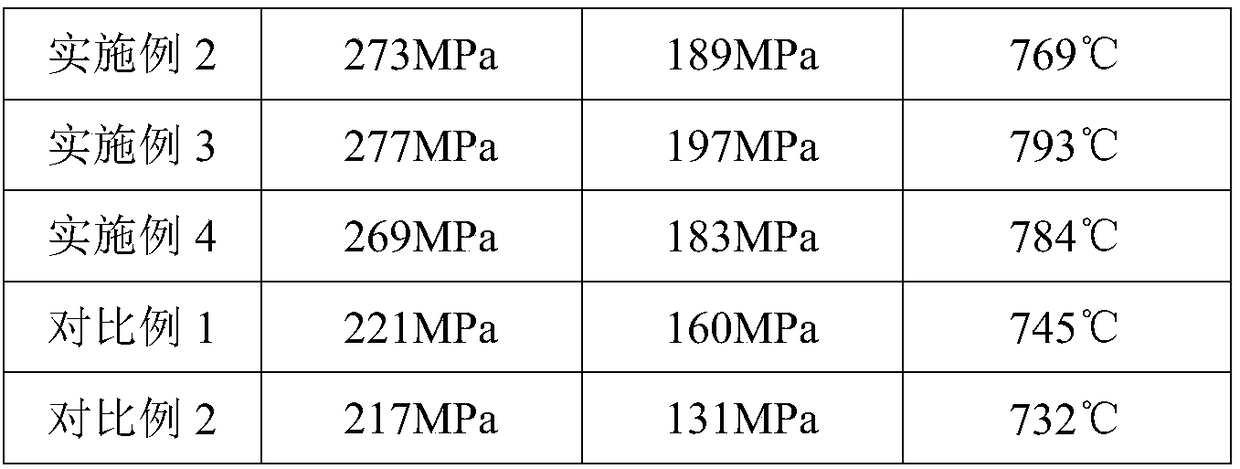

Embodiment 1

[0029] The corrosion-resistant rare earth magnesium alloy in this embodiment is composed of the following components in mass percentage: 7.0% Al, 1.0% Zn, 0.4% Mn, 0.5% Nd, 0.9% Gd, 0.7% Ag, 0.9% Sn, the balance It is Mg and unavoidable impurities; the total mass of Fe, Cu and Ni in the impurities accounts for less than 0.2% of the mass percentage of the rare earth magnesium alloy.

Embodiment 2

[0031] The corrosion-resistant rare earth magnesium alloy in this embodiment is composed of the following components in mass percentage: 7.5% Al, 1.0% Zn, 0.4% Mn, 0.5% Nd, 0.9% Gd, 0.7% Ag, 1.0% Sn, the balance It is Mg and unavoidable impurities; the total mass of Fe, Cu and Ni in the impurities accounts for less than 0.2% of the mass percentage of the rare earth magnesium alloy.

Embodiment 3

[0033] The corrosion-resistant rare earth magnesium alloy in this embodiment is composed of the following components in mass percentage: 7.5% Al, 0.9% Zn, 0.5% Mn, 0.6% Nd, 0.8% Gd, 0.8% Ag, 0.9% Sn, the balance It is Mg and unavoidable impurities; the total mass of Fe, Cu and Ni in the impurities accounts for less than 0.2% of the mass percentage of the rare earth magnesium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com