Corrosion-resistant self-assembled doped film layer on aluminum alloy surface and preparation method of corrosion-resistant self-assembled doped film layer

A technology of aluminum alloy surface and self-assembled film, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problem of low surface hardness, limited application range of aluminum alloy, poor wear resistance and corrosion resistance, etc. problems, achieve the effects of short film forming time, low corrosion current density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

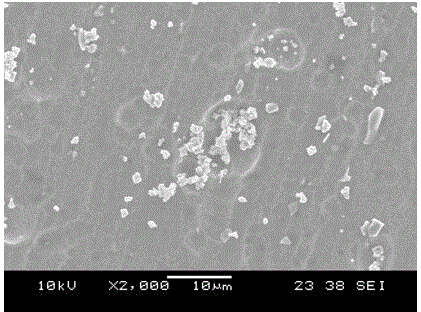

Image

Examples

Embodiment

[0014] (1) The aluminum alloy is first removed by NaOH solution with a concentration of 40 g / L to remove the aluminum-clad layer on the surface; then it is polished to smooth with 600#, 1000# and 1200# sandpaper in turn, and cleaned with analytical pure acetone and ultrasonic waves for 15 minutes; then Use a NaOH solution with a concentration of 4 mol / L to wash with alkali at 25°C for 1 minute, and finally wash with deionized water for 3 times, and dry it for use.

[0015] (2) Prepare anhydrous ethanol and bis(γ-triethoxysilylpropyl)tetrasulfide at a volume ratio of 85:15 to make a mixed solution with a total volume of 100 mL, and wait for the solution to age for 5 h to stabilize , add 15mL polyethylene glycol 200, ultrasonically shake for 90 min, and add 300 mg TiO 2 fine particles to disperse them evenly, and finally add analytically pure acetic acid dropwise to adjust the pH value of the solution to 6 for later use.

[0016] (3) Immerse the ready-to-use aluminum alloy trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com