Wind-proof dust-suppression method for open bulk materials stacking field, and its wind-proof dust-suppression net and use

A wind-proof and dust-suppressing net and material pile technology, which is applied in the direction of building types, buildings, fences, etc., can solve the problems of large dust, the limitation of dust suppression effect, and the angle of wind-proof and dust-suppressing net can not be adjusted properly with the change of wind direction, etc., to achieve Improvement of mechanical strength and wind resistance, improvement of dust suppression effect, effect of suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1. The invention discloses a windproof and dust-suppressing method for an open-air bulk material storage yard. Include the following steps:

[0027] (1) Build concrete foundations around the open-air bulk material storage yard;

[0028] (2) Fix and support the steel structure on the concrete foundation;

[0029] (3) Install wind-proof and dust-suppressing mesh panels on the supporting steel structure;

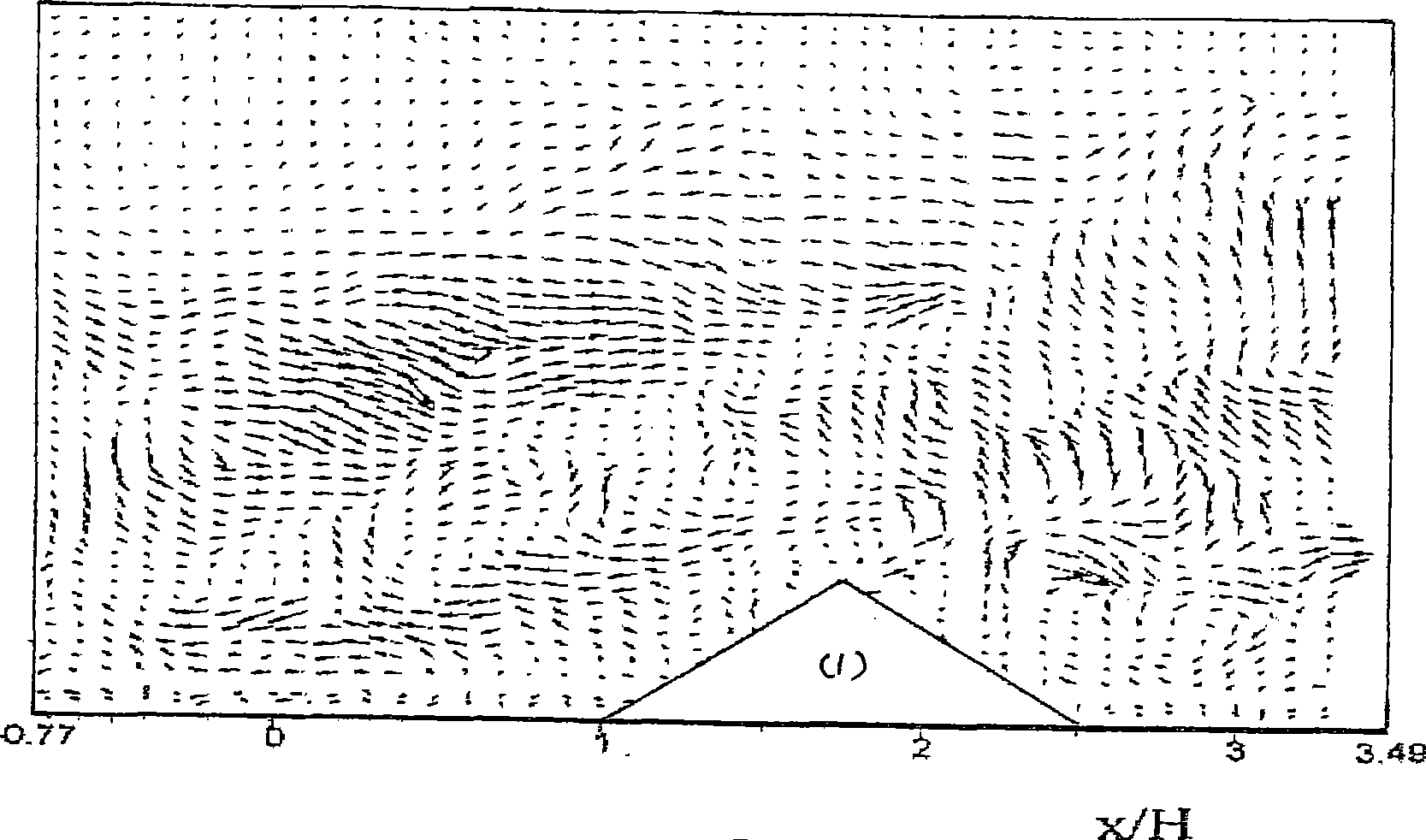

[0030] (4) The installed wind-proof and dust-suppressing nets have two structures: wind-shielding nets and dust-blocking nets. The wind-shielding nets are set on the mainstream wind surface, mainly to reduce the wind intensity, and the dust-blocking nets are set on other secondary wind surfaces. , which mainly intercepts the escape of dust particles raised by the mainstream wind. When the wind direction changes so that the dust blocking device is in the mainstream wind direction, the dust blocking device will play a role in reducing the wind strength, and othe...

Embodiment 2

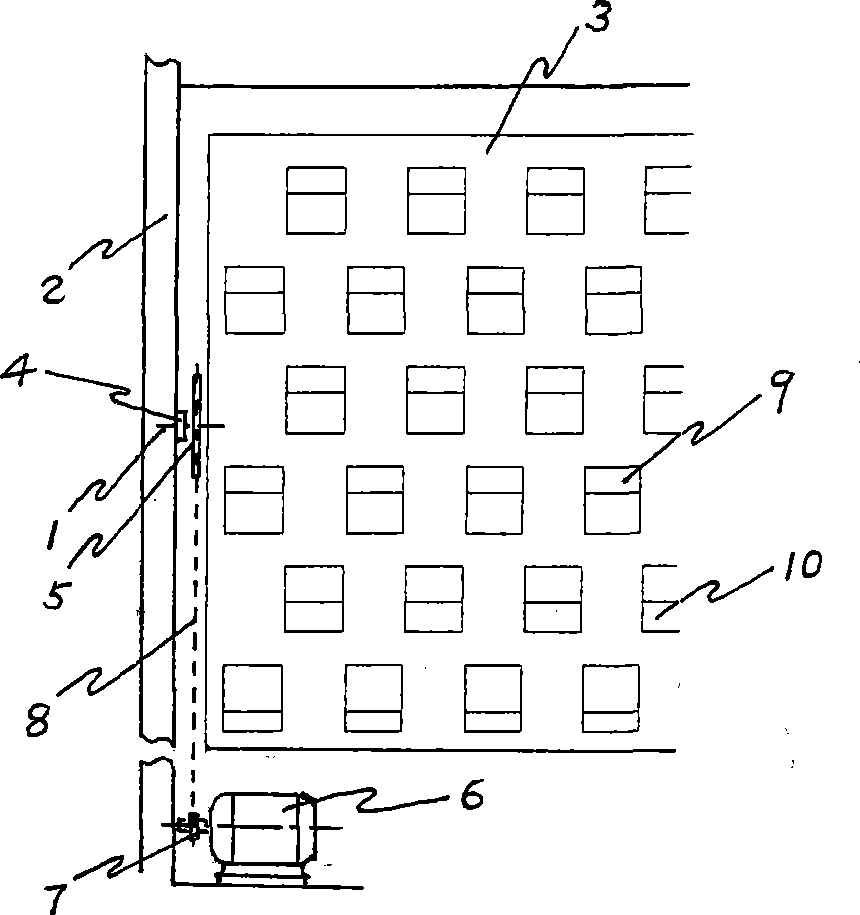

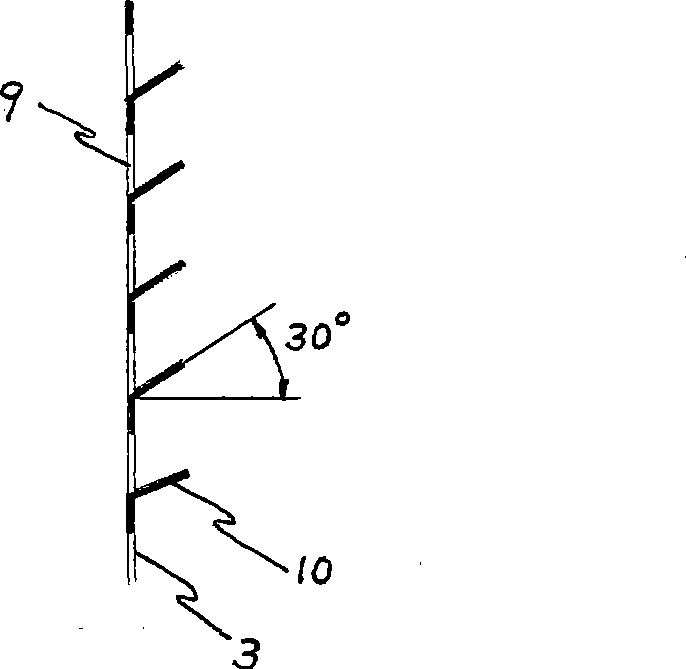

[0040]Example 2. A windproof and dust suppression net, such as Figure 1 ~ Figure 2 shown. It includes the concrete foundation fixed around the open-air bulk material pile, the supporting steel structure 2 fixed on the concrete foundation, and the web installed on the supporting steel structure 2. Shafts 1 are fixed on the left and right sides of the middle 3 rows of windshield valves 3 arranged on the mainstream wind surface, and two left and right bearings 4 are fixed on the corresponding positions on both sides of the supporting steel structure 2, and the shaft 1 is installed on the left and right bearings 4 middle. The driven sprocket 5 is also fixedly installed on the shaft 1. A motor 6 is fixedly installed on the supporting steel structure 2 , and a drive sprocket 7 is fixedly installed on the shaft of the motor 6 . Drive chain 8 is installed on driving sprocket 7 and driven sprocket 5. The mesh 9 on its web 3 is a long hole, and one side of the mesh 9 is stamped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com