Full-digitalized monitoring method for water for power plants and self-balance water affair system

A fully digital, self-balancing technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as waste of water resources, reduce pollution, save resources, reduce The effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

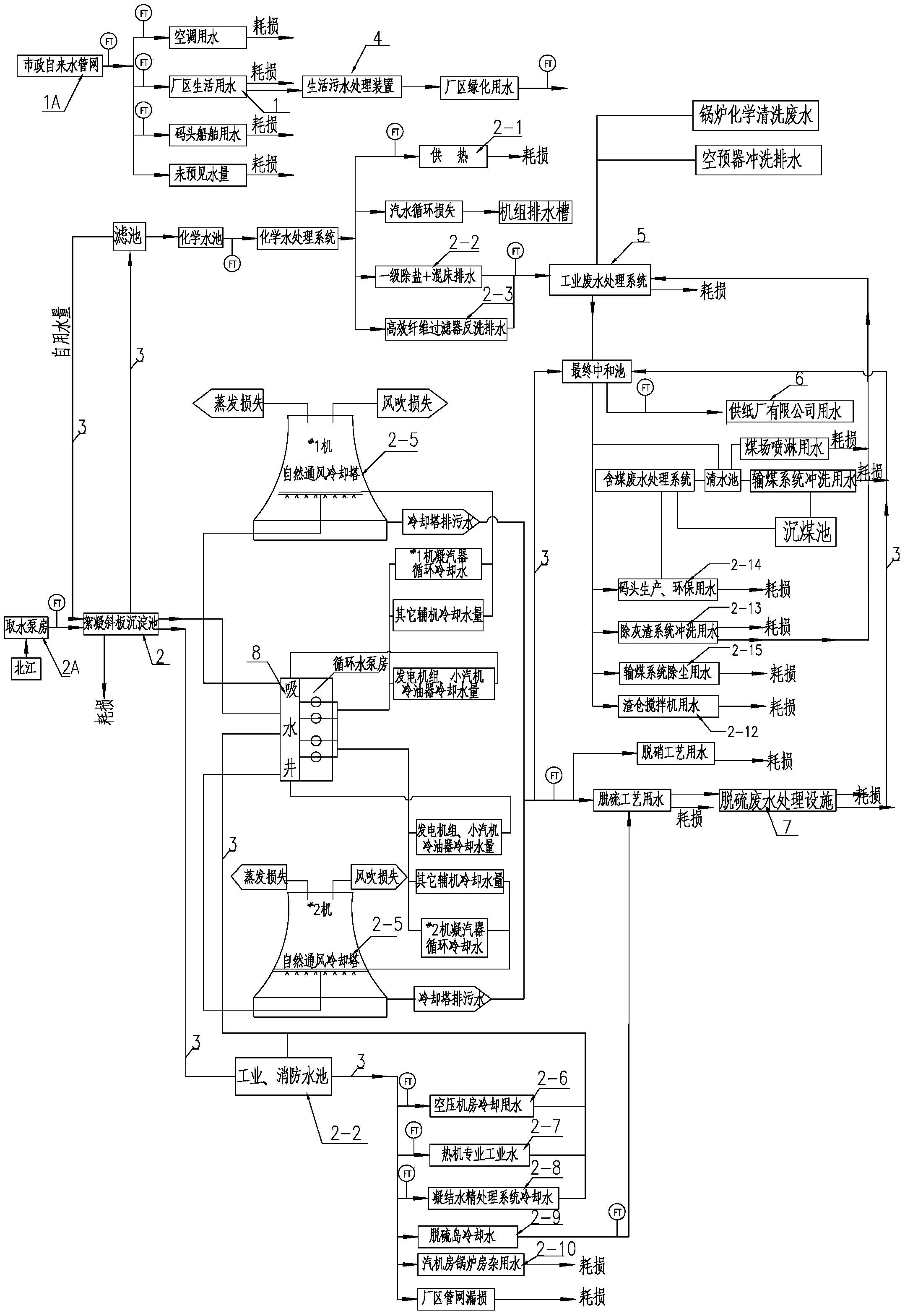

[0032] refer to figure 1 , the fully digitalized self-balancing water system of the power plant water system monitoring involved in this embodiment includes a control system, a water supply system and a drainage system, and the water supply system and the drainage system are connected as one through the field bus technology control system to form a power plant water system; the water supply system There are two water intake channels for reservoir water intake and municipal tap water. The water outlet of the water supply system is connected to the water inlet of the domestic water system 1 and the industrial water system 2 in the power plant to form a water delivery network 3; the water inlet of the drainage system is connected to the domestic water system. 1 and the drainage end of the industrial water system 2 constitute a drainage pipe network; at all the water inlet ends of the domestic water system 1 and the industrial water system 2, a digital flow transmitter is installed...

specific Embodiment 2

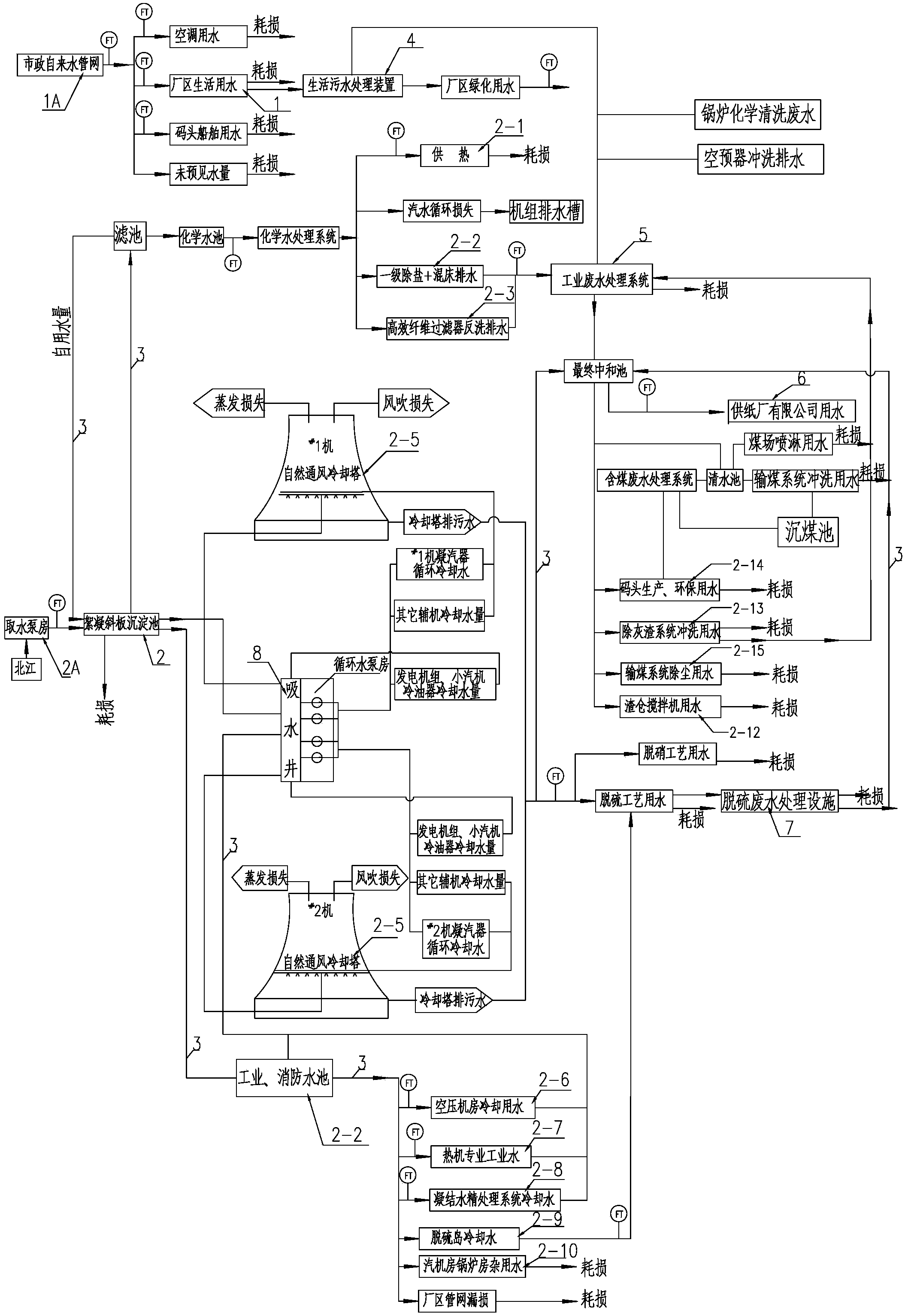

[0040] refer to figure 2 , the characteristics of this embodiment are: the sewage of the domestic water 1 is transported to the domestic sewage treatment device 4 through the sewage pipe for treatment, and then transported to the industrial water pipe network. When in use, when the sewage of the domestic sewage treatment device is detected After treatment, when the storage of water for greening is saturated, the sewage discharge of the domestic sewage treatment device 4 is controlled through the control system of the water affairs center. If it is detected that the discharged sewage reaches the standard that can be directly supplied to industrial water, it is directly transported to the circulation of the industrial water 2 pipe network If it is detected that the water pipe cannot meet the industrial water standard, it will be transported to the industrial wastewater treatment system 5 for further treatment before use. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com