Method and system for capturing CO2 by temperature-lowering absorption and low-voltage desorption

A technology of adsorption and desorption and CO2, which is applied in the field of capturing CO2, can solve the problems of atmospheric secondary pollution, large energy consumption, and difficult control, and achieve the effects of increasing adsorption capacity, improving utilization efficiency, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

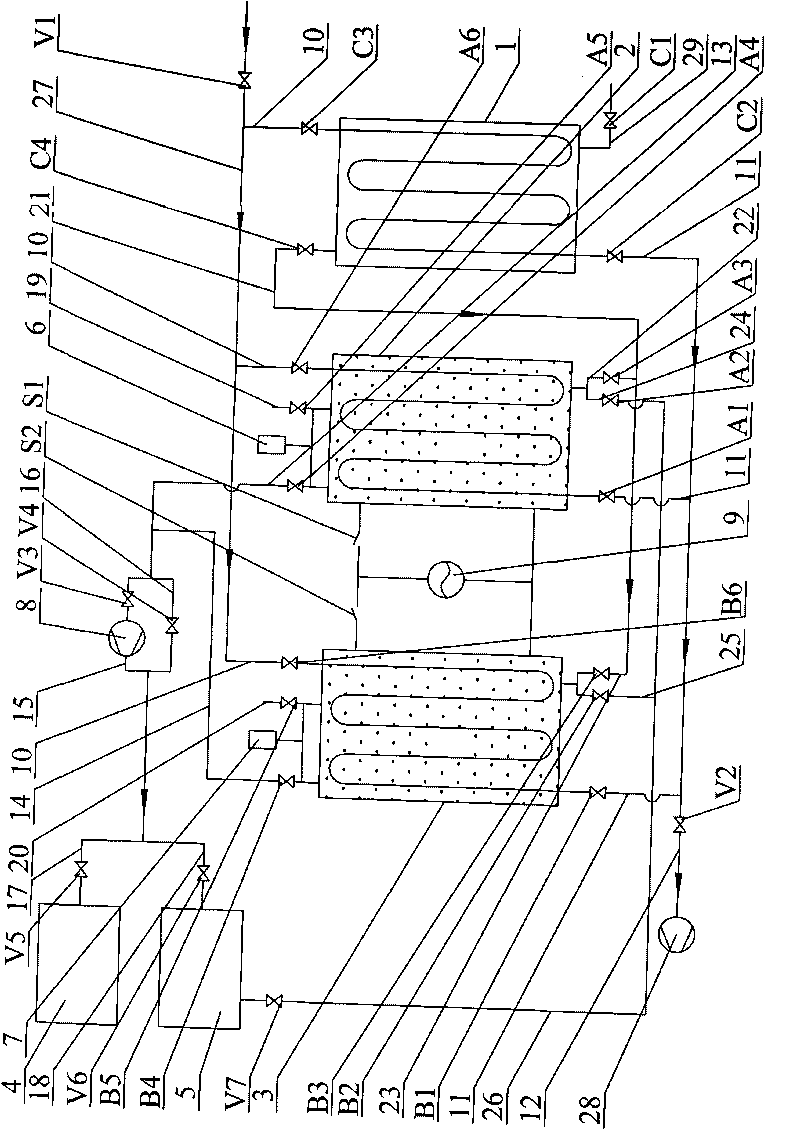

[0019] Specific implementation mode one: combine figure 1 Describe this embodiment, the temperature-lowering adsorption and low-voltage electric desorption of this embodiment captures CO 2 The method includes the following steps:

[0020] Step 1, flue gas cooling: flue gas in coal-fired power plants is removed by SO 2 and NO X Afterwards, the temperature drops to between 50°C and 60°C, and the above-mentioned cooled flue gas is passed into the heat exchanger 1 and exchanged with low-temperature tap water, so that the temperature of the flue gas passed into the heat exchanger 1 is reduced to 20°C. Between ℃-30℃ (because CO 2 The critical temperature of the adsorbent is below 31°C, and the adsorption capacity of the adsorbent is greater, and the lower the temperature, the better the CO 2 The greater the adsorption capacity, but at the same time the low temperature adsorbs N on the adsorbent 2 is also beneficial, so in order to obtain a high concentration of CO 2 , the adso...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment also includes step 21 between step 2 and step 3 in the next adsorption-desorption cycle process of the first adsorption-desorption tower 2: that is, CO 2 Purging step: the mole percentage stored in the buffer tank 5 in the last adsorption-desorption cycle reaches 80%-85% CO 2 Pass into the first adsorption-desorption tower 2 from bottom to top, and replace part of the N in the free space in the first adsorption-desorption tower 2 2 , when the first gas analyzer 6 shows that the CO at the flue gas outlet of the first adsorption-desorption tower 2 The mole percentage reaches the CO at the flue gas inlet of the first adsorption-desorption tower 2 When the concentration is 40%-50%, the process ends, and the next step, namely step three, is carried out.

[0029] During the adsorption process of the first adsorption-desorption tower 2, there is not only CO in the adsorption pha...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 Describe this embodiment, a kind of low-temperature adsorption and low-voltage electric desorption of this embodiment to capture CO 2 The system consists of heat exchanger 1, first adsorption-desorption tower 2, second adsorption-desorption tower 3, gas collection tank 4, buffer tank 5, first gas analyzer 6, second gas analyzer 7, vacuum pump 8, AC power supply 9, first switch S1, second switch S2, first valve C3, second valve A6, third valve B6, fourth valve C2, fifth valve A1, sixth valve B1, seventh valve A4, Eighth valve B4, ninth valve V3, tenth valve V4, eleventh valve V5, twelfth valve V6, thirteenth valve A3, fourteenth valve A2, fifteenth valve B3, sixteenth valve B2, Seventeenth valve C4, eighteenth valve V7, nineteenth valve A5, twentieth valve B5, three water inlet pipes 10, three water outlet branch pipes 11, main water outlet pipe 12, first flue gas pipe 13, second flue gas pipe 14. The third flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com