Anaerobic ammonoxidation bacterium concentrating device

A technology for the enrichment of anammox bacteria, which is applied in the field of anammox bacteria enrichment devices, can solve the problems of difficulty in obtaining enrichment cultures and low cell yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

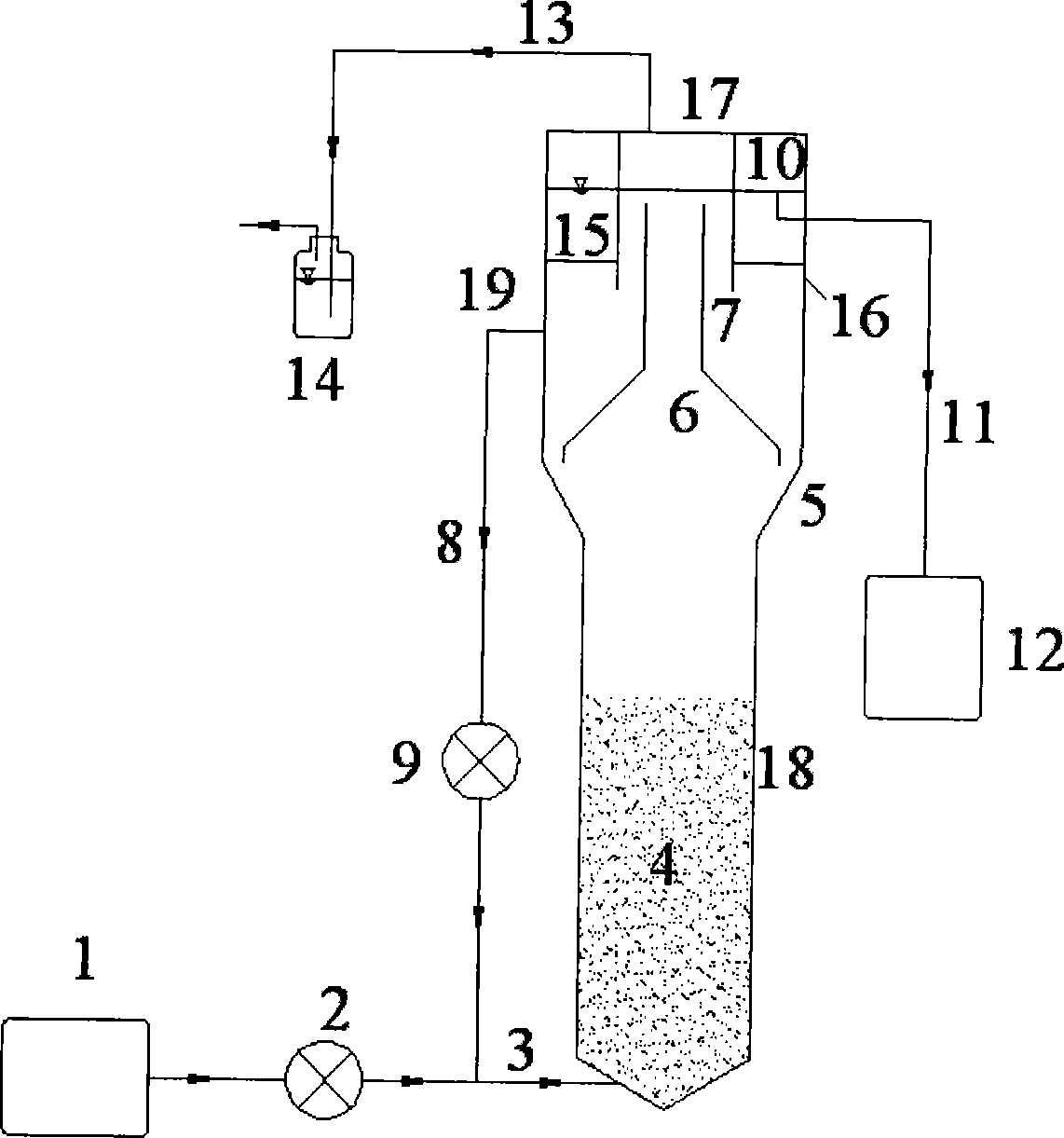

[0009] As shown in the drawings, the anammox bacteria enrichment device has a device body, the lower cylinder 18 of the device body is connected with the upper cylinder 19 through the expanding tube 5, and the top of the upper cylinder 19 is provided with a sealing cover 17, which is sealed. The cover 17 is provided with an exhaust pipe 13 and is connected with the gas washing bottle 14, the bottom of the lower cylinder 18 is equipped with a granular bamboo charcoal carrier 4, and the upper cylinder 19 is equipped with a first-level gas-liquid-solid three-phase separation assembly 6, a The second stage gas-liquid-solid three-phase separation assembly 6 is provided with a secondary mud-water separation assembly 7, and a granular sludge interception assembly 15 is provided between the secondary mud-water separation assembly 7 and the upper cylinder 19. Below the granular sludge interception assembly 15 , the side wall of the upper cylinder 19 is provided with a granular sludge co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com