Five-nozzle combustor structure applied to gas turbine low-pollution combustion chamber

A technology of nozzle burners and gas turbines, which is applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., and can solve the problems of high NOx emissions and long residence time

Active Publication Date: 2015-06-24

SHANGHAI JIAO TONG UNIV

View PDF12 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is a long residence time of high-temperature reactants in the combustion chamber, resulting in higher NOx emissions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

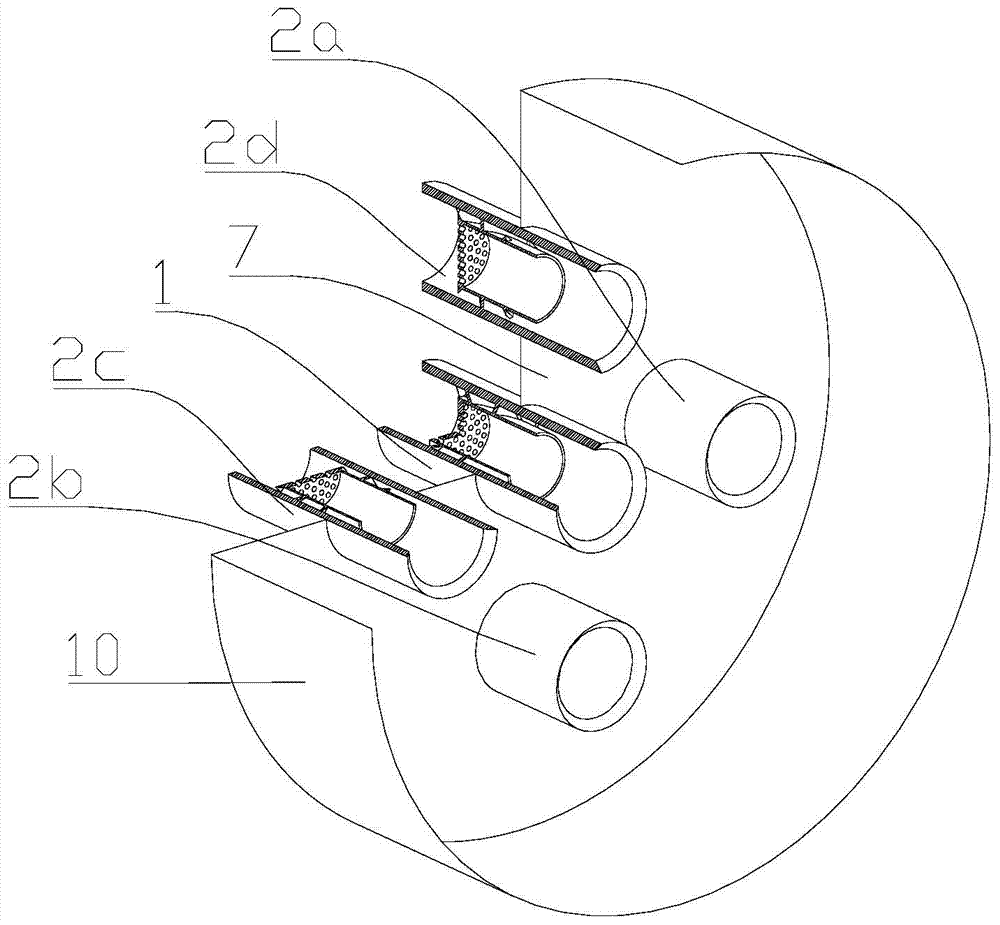

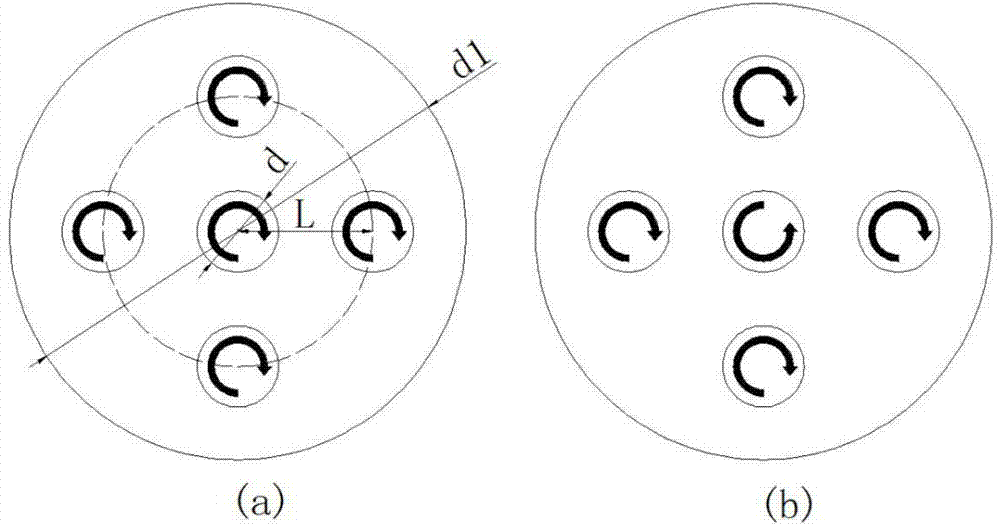

[0026] Figure 6 It is a schematic diagram of the combustion chamber arrangement of a five-nozzle burner. As shown in the figure, in the specific arrangement, the five-nozzle combustor can be arranged as a tubular combustion chamber or an annular tubular combustion chamber according to the structure of the actual gas turbine.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

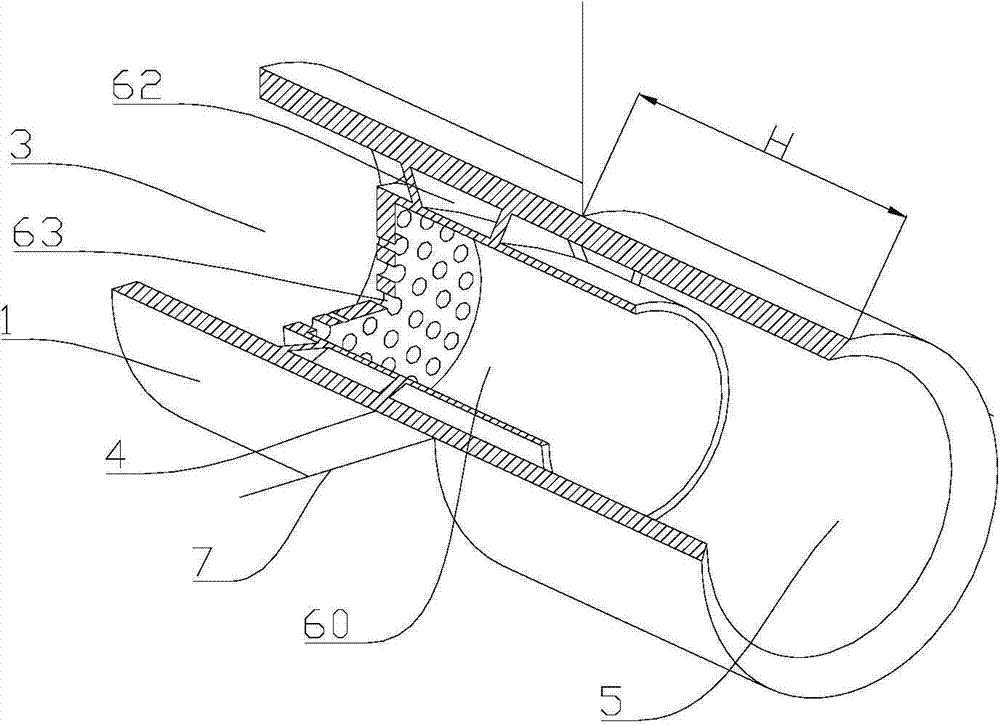

The invention discloses a five-nozzle combustor structure applied to a gas turbine low-pollution combustion chamber, the combustor is composed of five low-swirl nozzles, the surrounding nozzles are arranged evenly at equal intervals in the circumferential direction along the central nozzle, and the swirling flow directions of the surrounding nozzles are the same. The swirling flow direction of the central nozzle is the same as or opposite to the swirling flow directions of the surrounding nozzles. Lean premixed combustion of gas fuel and air is adopted, the flame residence time is reduced, the flame temperature is reduced, and the aim of low emission is achieved. The five-nozzle combustor structure applied to the gas turbine low-pollution combustion chamber has the advantages of being stable in combustion, low in emission, low in noise, reasonable in design, simple in structure, and suitable for the gas turbine low-pollution combustion chamber.

Description

technical field [0001] The invention relates to the technical field of gas turbines, in particular to a five-nozzle burner structure suitable for low-pollution combustion chambers of gas turbines. Background technique [0002] The swirl stable combustion technology is widely used in gas turbine combustors. Traditional high-swirl burners use the recirculation zone created by the swirl to speed up the mixing of high-temperature combustion products with fresh reactants, thereby stabilizing the flame. However, there is a long residence time of high-temperature reactants in the combustion chamber, resulting in higher NOx emissions. Low-swirl combustion refers to maintaining stable flame combustion with a low swirl number (the swirl number is generally between 0.4 and 0.55). Compared with high-swirl combustion, there is no severe backflow zone in the low-swirl flow field , the streamline expands at the exit of the nozzle, resulting in a decrease in air velocity, and the flame st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23R3/38

Inventor 柳伟杰葛冰臧述升

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com