Preparation method of large-size aluminum alloy ingot

An aluminum alloy ingot, large-scale technology, applied in the field of preparation of aluminum alloy ingot, can solve the problems of difficult forming, easy cracking, etc., achieve the effect of good surface quality, increase plasticity, and improve castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

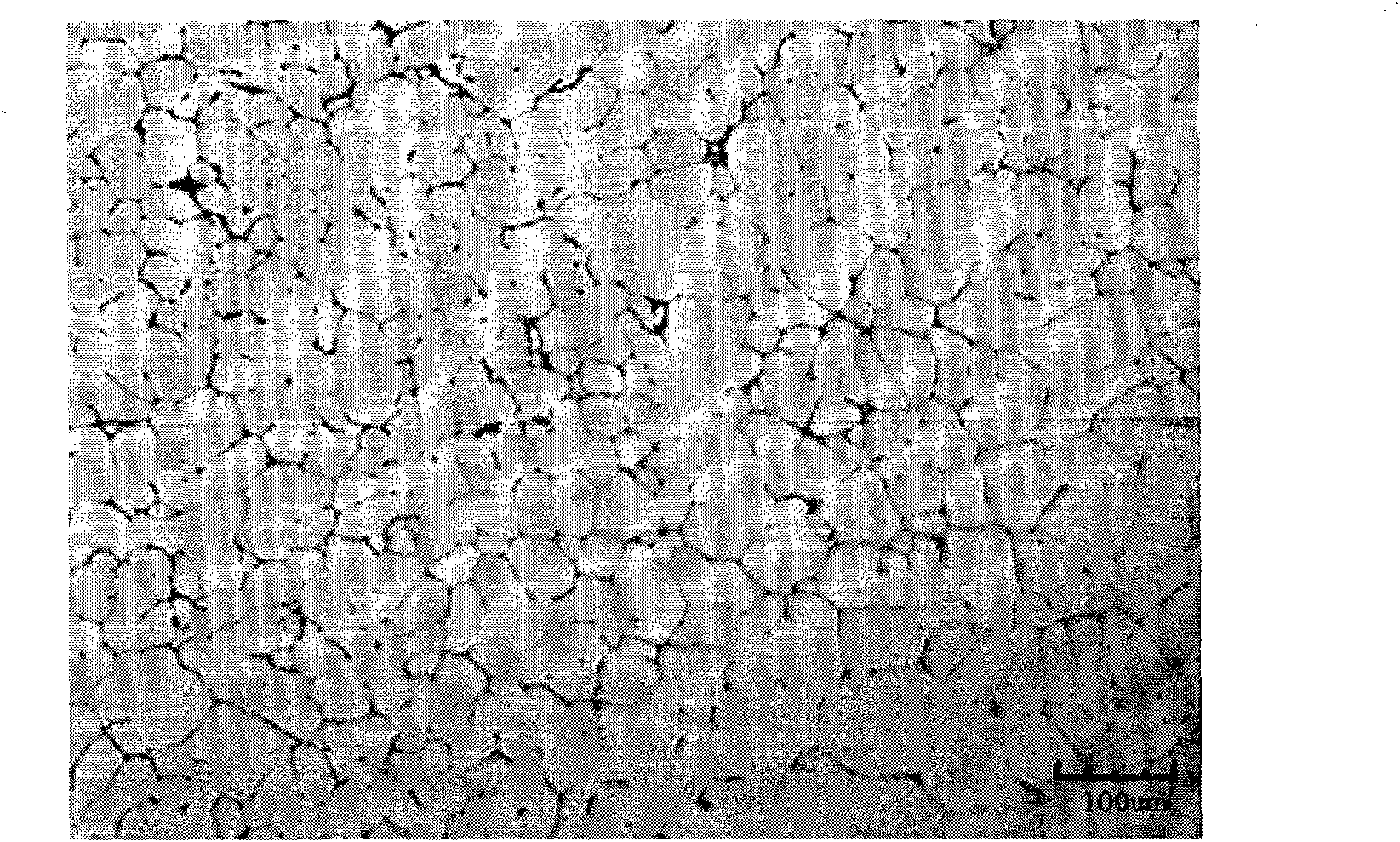

[0014] Specific Embodiment 1: The preparation method of a large-scale aluminum alloy ingot in this embodiment is carried out according to the following steps: 1. According to the mass percentage of elements in the aluminum alloy ingot Si: 0.01% to 0.20%, Fe: 0.02% to 0.30%, Cu: 3.8%-4.9%, Mn: 0.3%-0.9%, Mg: 1.2%-1.8%, Cr: 0.01%-0.10%, Zn: 0.01%-0.25%, Ti: 0.01%-0.15% , Al: 91.40% ~ 94.64% and Fe>Si Weigh aluminum ingots, electrolytic copper, magnesium ingots, zinc ingots, aluminum-silicon master alloys, aluminum-iron master alloys, aluminum-manganese master alloys, aluminum-chromium master alloys and aluminum-titanium master alloys Alloy; 2. Take 1# flux and covering agent, wherein the quality of 1# flux is 0.5%~0.6% of the total mass of all materials weighed in step 1, and the quality of covering agent is all materials weighed in step 1 0.5% to 0.6% of the total mass; 3. Weigh the 1# flux in step 2 and spread it evenly on the bottom of the melting furnace, and then add the ma...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the 1# flux described in step two is made of 50% KCl, 26% NaCl and 24% NaAlF by weight percentage 6 Composition of mixed powder. Others are the same as in the first embodiment.

[0019] In this embodiment, KCl, NaCl and NaAlF 6 All are commercially available.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the covering agent in step 2 is a mixed powder composed of 50% KCl and 50% NaCl by weight. Others are the same as in the first or second embodiment.

[0021] In this embodiment, both KCl and NaCl are commercially available.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com