Bioreactor applied to magnetic nano-catalyst

A bioreactor, magnetic nanotechnology, applied in biochemical instruments, biochemical equipment and methods, methods of stress-stimulated microbial growth, etc., can solve the problems of poor mixing effect, low flexibility, complex structure, etc. Easy disassembly, high flexibility, and precise control of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

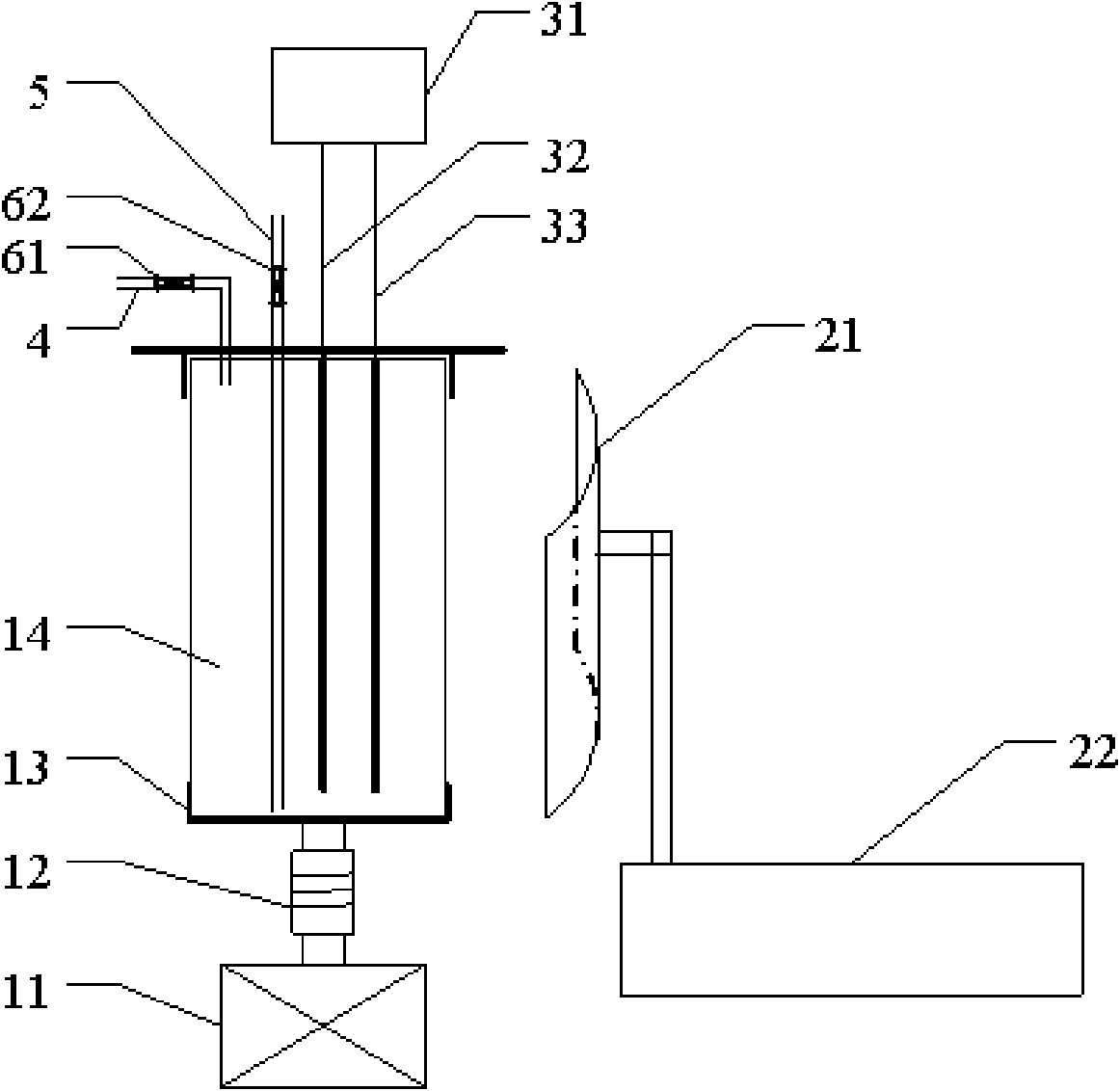

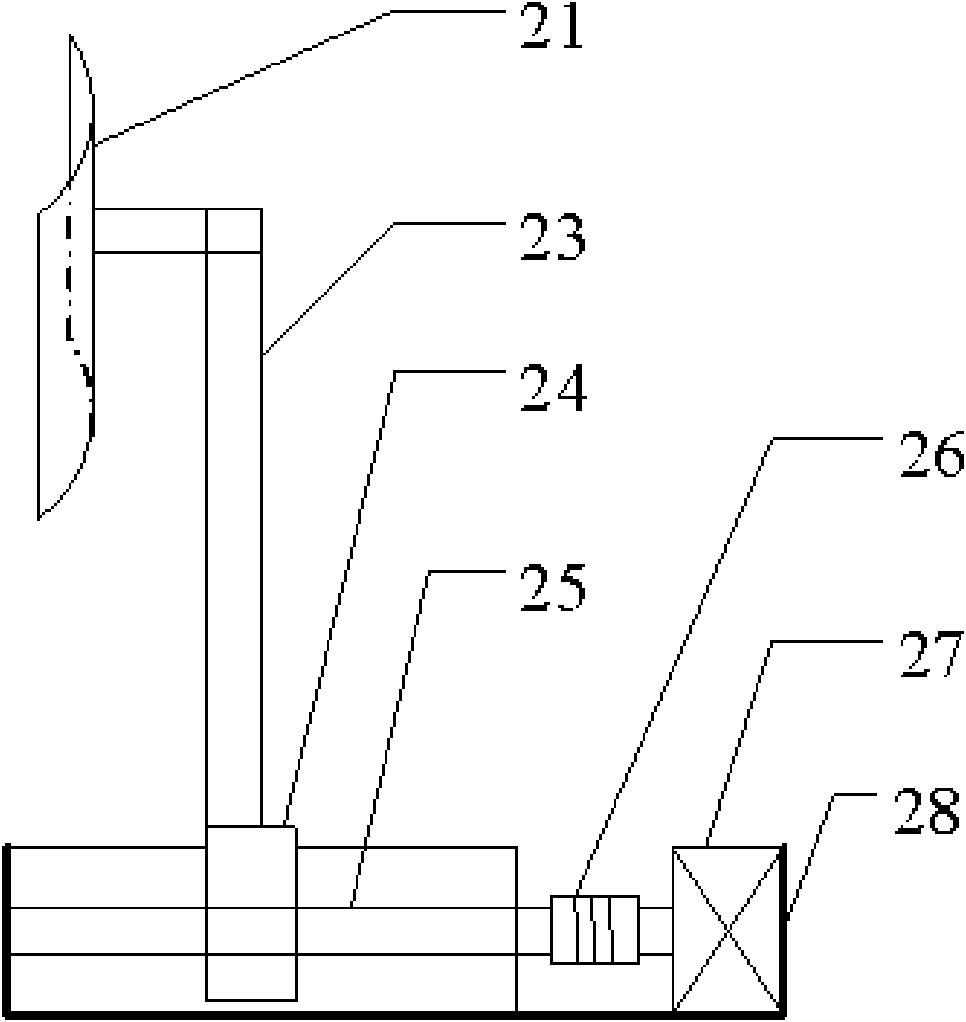

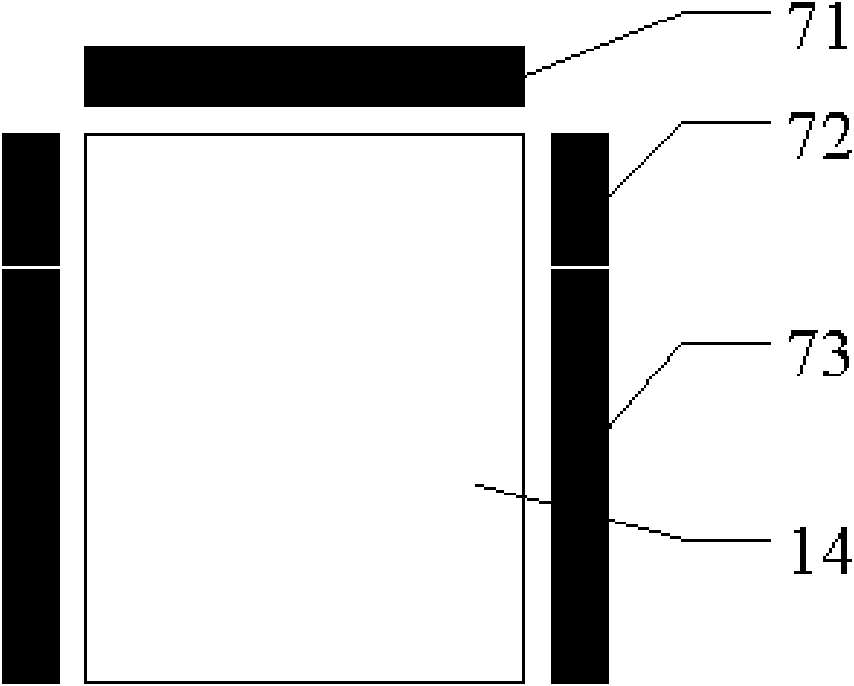

[0015] The bioreactor provided by the invention includes a mixing device, a recovery device and a temperature control device. The reaction is fully carried out through the mixing device that fully mixes the catalyst and the reaction liquid, and the reaction efficiency is improved. The temperature is kept at the optimum temperature of the reaction through the temperature control device to facilitate the reaction, and the catalyst used is recovered through the recovery device. Utilize, improve the use efficiency of the catalyst, save cost and reduce pollution. The driving part in the above-mentioned device for fully mixing the catalyst and the reaction solution can be realized by means of a motor, or by an electromagnet. The motor mode referred to is: through the combination of the motor and the reaction vessel, the effect of fully mixing the catalyst and the reaction solution can be achieved. The electromagnet method referred to is to achieve the effect of fully mixing the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com