Composite metamorphic agent and composite metamorphic method of cast aluminum-silicon alloy

A technology of casting aluminum-silicon alloy and composite modifier, which is applied in the field of casting aluminum alloy modification, and can solve the problem that the synchronous refinement of eutectic silicon and α-Al grains cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

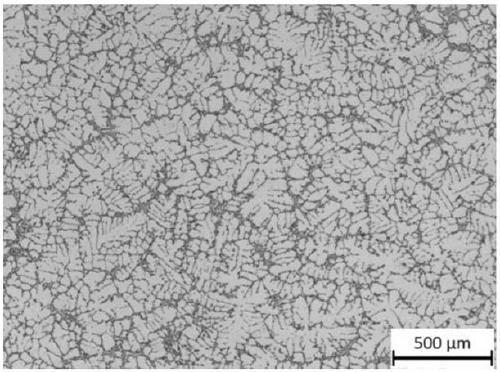

[0047] This embodiment provides a method for compound modification of cast aluminum-silicon alloy, which includes the following steps:

[0048] S1: Put the prepared alloy raw materials into the melting furnace, heat the raw materials to 500°C, keep them warm for 30 minutes, and then raise the temperature to 750°C;

[0049] S2: After all the raw materials are melted, the melt temperature is lowered to 700°C. The aluminum melt is subsequently refined in-line.

[0050] S3: Remove slag after 15 minutes of heat preservation, add Al-Ti-B and Al-Sr master alloys wrapped in aluminum foil, and the amount of Al-Ti-B and Sr added is 0.02% of the mass of the melt respectively , 0.04%, and then press it into the melt with a titanium tool, and slowly stir the melt after melting to make it evenly distributed.

[0051] S4: The melt was left to stand for 60 minutes and then cast into an ingot to prepare a cast 1# aluminum alloy ingot.

[0052] After modification, the chemical composition of...

Embodiment 2

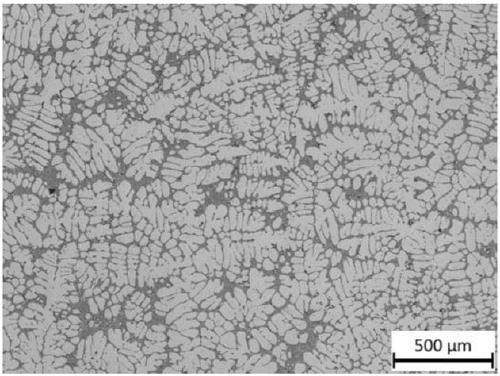

[0054] This embodiment provides a method for compound modification of cast aluminum-silicon alloy, which includes the following steps:

[0055] S1: Put the prepared alloy raw materials into the melting furnace, heat the raw materials to 500°C, keep them warm for 30 minutes, and then raise the temperature to 800°C;

[0056] S2: After all the raw materials are melted, the temperature of the melt is lowered to 710°C. The aluminum melt is subsequently refined in-line.

[0057] S3: After 30 minutes of heat preservation, remove the slag, add the preheated Al-Ti-B, Al-Sr, Al-RE master alloys wrapped in aluminum foil, and the addition amounts of Al-Ti-B, Sr, and RE are respectively 0.02%, 0.04%, and 0.05% of the mass of the melt are pressed into the interior of the melt with titanium tools, and after melting, the melt is slowly stirred to make it evenly distributed.

[0058] S4: The melt was left to stand for 60 minutes and then cast into an ingot to prepare a cast aluminum alloy in...

Embodiment 3

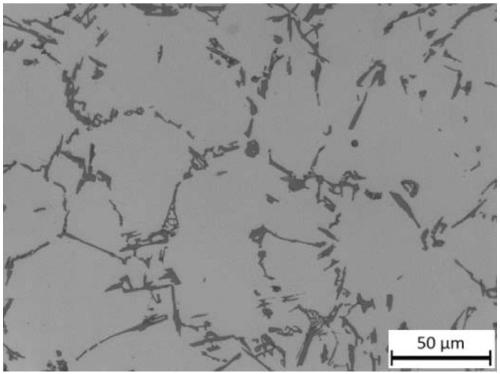

[0061] This embodiment provides a method for compound modification of cast aluminum-silicon alloy, which includes the following steps:

[0062] S1: Put the prepared alloy raw materials into the melting furnace, heat the raw materials to 500°C, keep them warm for 30 minutes, and then raise the temperature to 760°C;

[0063] S2: After all the raw materials are melted, the temperature of the melt is lowered to 720°C. The aluminum melt is subsequently refined in-line.

[0064] S3: After keeping warm for 20 minutes, remove the slag, add the preheated Al-Ti-B, Al-Sr, Al-RE master alloys wrapped in aluminum foil, and the addition amounts of Al-Ti-B, Sr, and RE are respectively 0.04%, 0.03%, and 0.05% of the mass of the melt are pressed into the interior of the melt with a titanium tool, and after melting, the melt is slowly stirred to make it evenly distributed.

[0065] S4: The melt was left to stand for 40 minutes and then cast into an ingot to prepare a cast aluminum alloy ingot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com