Surface processing method for self-lubricating joint bearing after hard chromium plating of spherical surface of inner ring of self-lubricating joint bearing

A joint bearing and surface processing technology, which is applied in the field of surface processing of the spherical surface of the inner ring of the self-lubricating joint bearing after hard chrome plating, can solve the problem of poor fit between the outer ring and the inner ring, wear failure of the bearing friction pair, and influence on the spherical surface roughness and other issues to achieve the effect of improving the shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

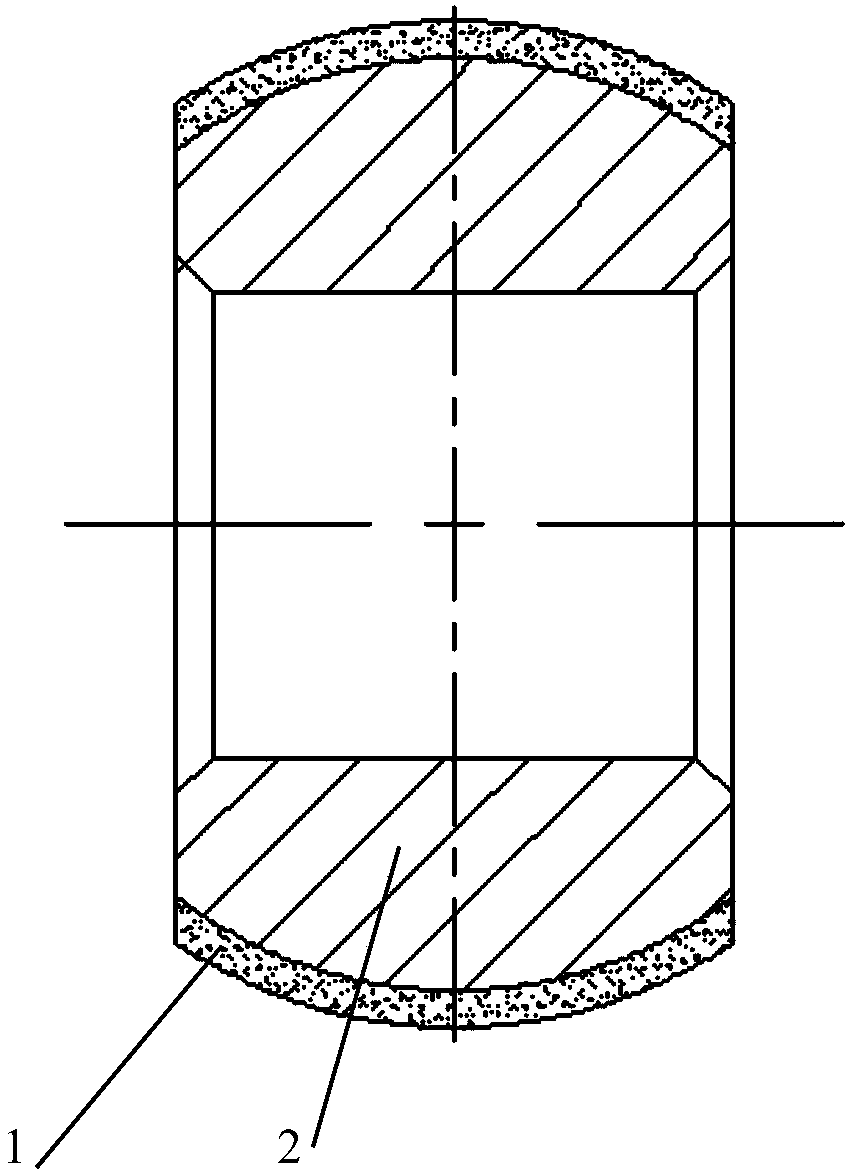

[0020] This embodiment relates to a surface processing method of the spherical surface of the inner ring of the self-lubricating joint bearing after being plated with hard chrome. The self-lubricating joint bearing is as follows: figure 1 As shown, it includes a hard chromium plating layer 1 and a self-lubricating spherical plain bearing inner ring 2, and its surface processing method includes the following steps:

[0021] 1. Prepare CNC spherical superfinishing machine, special pig iron rod for grinding, pneumatic tooling fixture for inner ring mandrel, abrasive paste, polishing cloth and hard chrome-plated bearing inner ring;

[0022] 2. Use a clamping tool to fix the inner ring of the bearing at the machining position of the machine tool, clamp the supporting pig iron rod to make the grinding surface stick to the spherical surface, coat the processing surface with 8000SiC grinding paste, set the process parameters spindle speed 200-250rpm, grinding head speed 300 ~ 350rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com