Making technology of sensor packaging sheet

A manufacturing process and packaging sheet technology, applied in the field of sensor packaging sheet manufacturing process, can solve the problems of complex production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

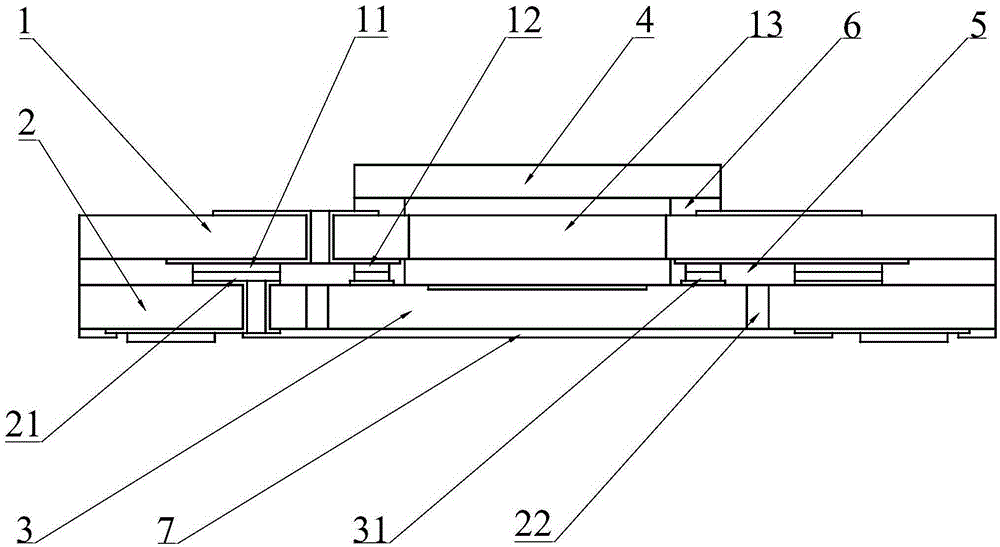

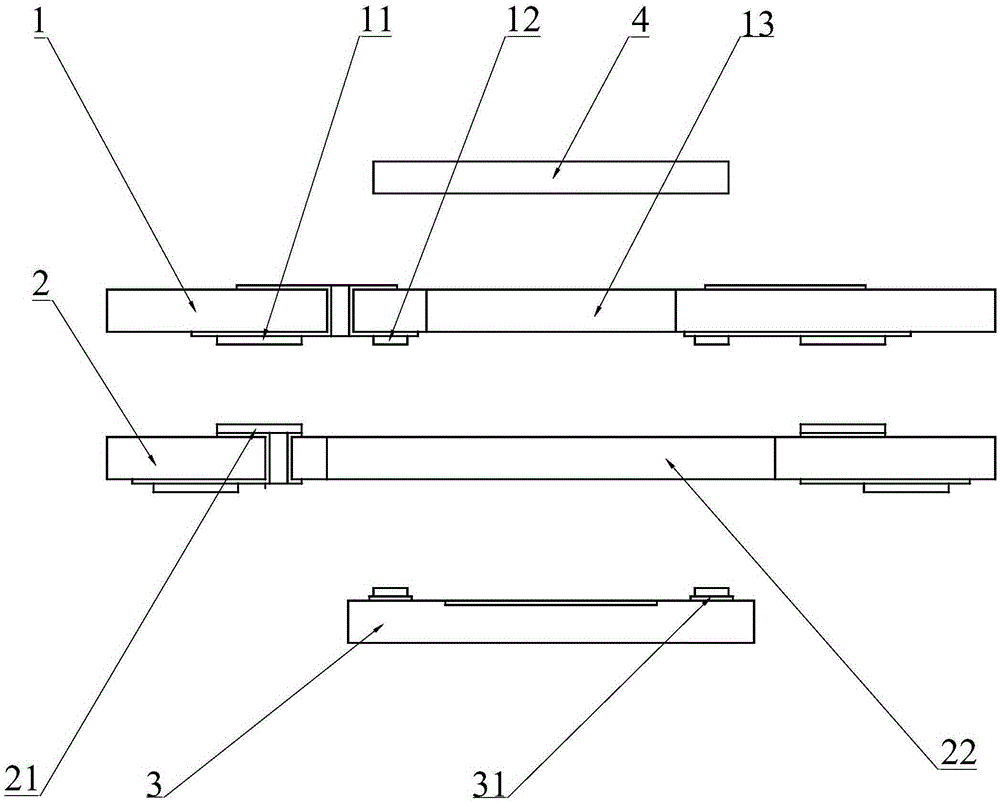

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] see figure 1 and figure 2 As shown, the technical solution of the present invention is to provide a manufacturing process of a sensor packaging sheet, which is characterized in that: the manufacturing process includes the following steps:

[0026] a) Select the upper substrate, the lower substrate and some chips and pre-process them;

[0027] b) coating the bottom surface of the upper substrate with a first adhesive material, and sequentially performing exposure, PEB and development on the first adhesive material;

[0028] c) bonding the bottom surface of the upper substrate to the top surface of the lower substrate;

[0029] d) Selecting a plurality of chips, the lower substrate is arranged with a number of placement holes, and the chips pass through the placement holes from the bottom surface of the lower substrate to the top surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com