Robot arm component, manufacturing method thereof and robot with arm component

A technology of arm parts and robots, which is applied in the direction of manufacturing tools, claw arms, manipulators, etc., can solve the problems of increased casting difficulty, large length, and complex sand molds, and achieve the effects of improving shape accuracy, improving utilization rate, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The arm part of the robot of the present invention, its manufacturing method and the robot with the arm part will be further described in detail below in conjunction with the drawings and embodiments.

[0018] The arm part of the present invention can be applied to linear coordinate, cylindrical coordinate, spherical coordinate and articulated robots, and this embodiment is described by taking the application to six-axis articulated robots as an example.

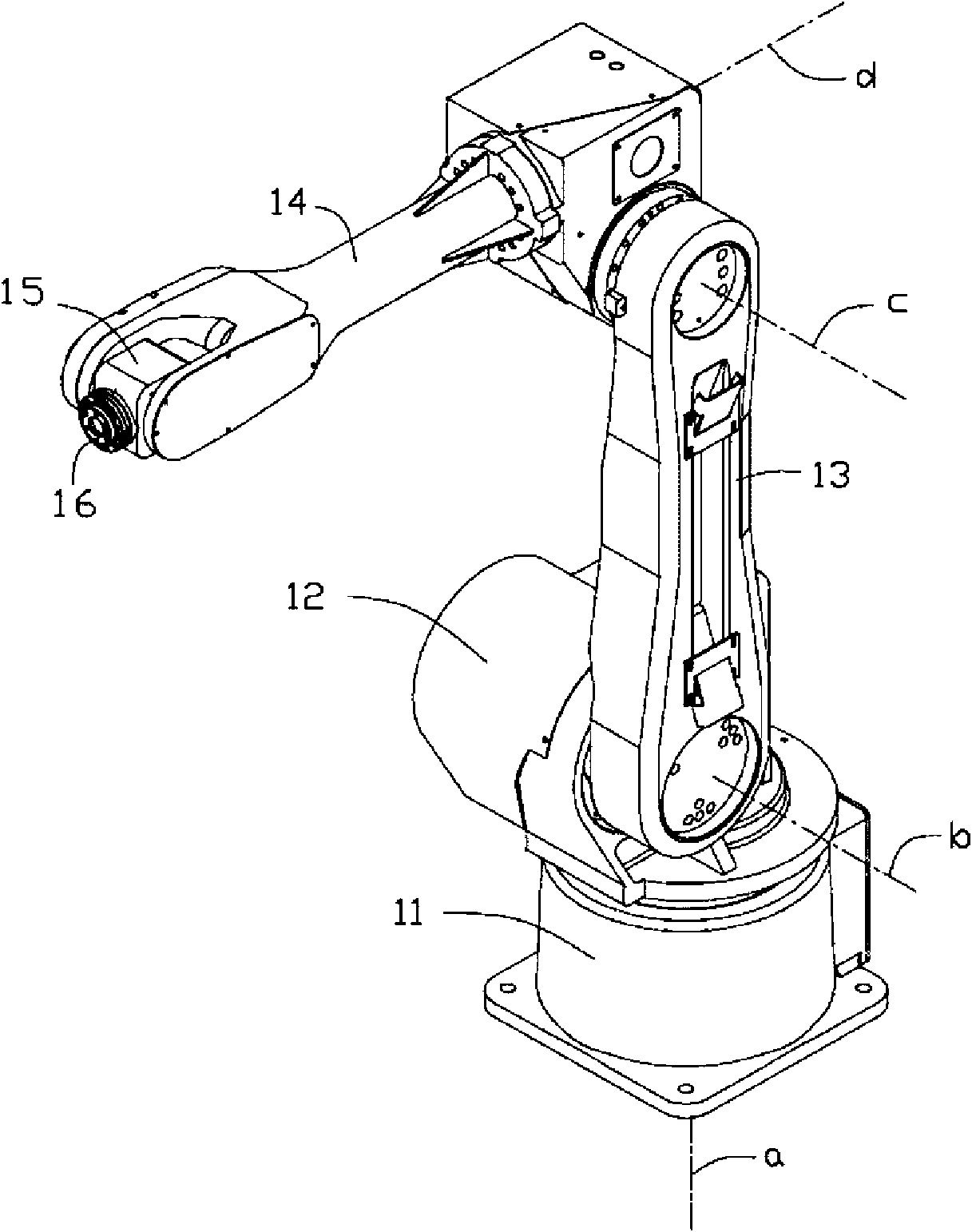

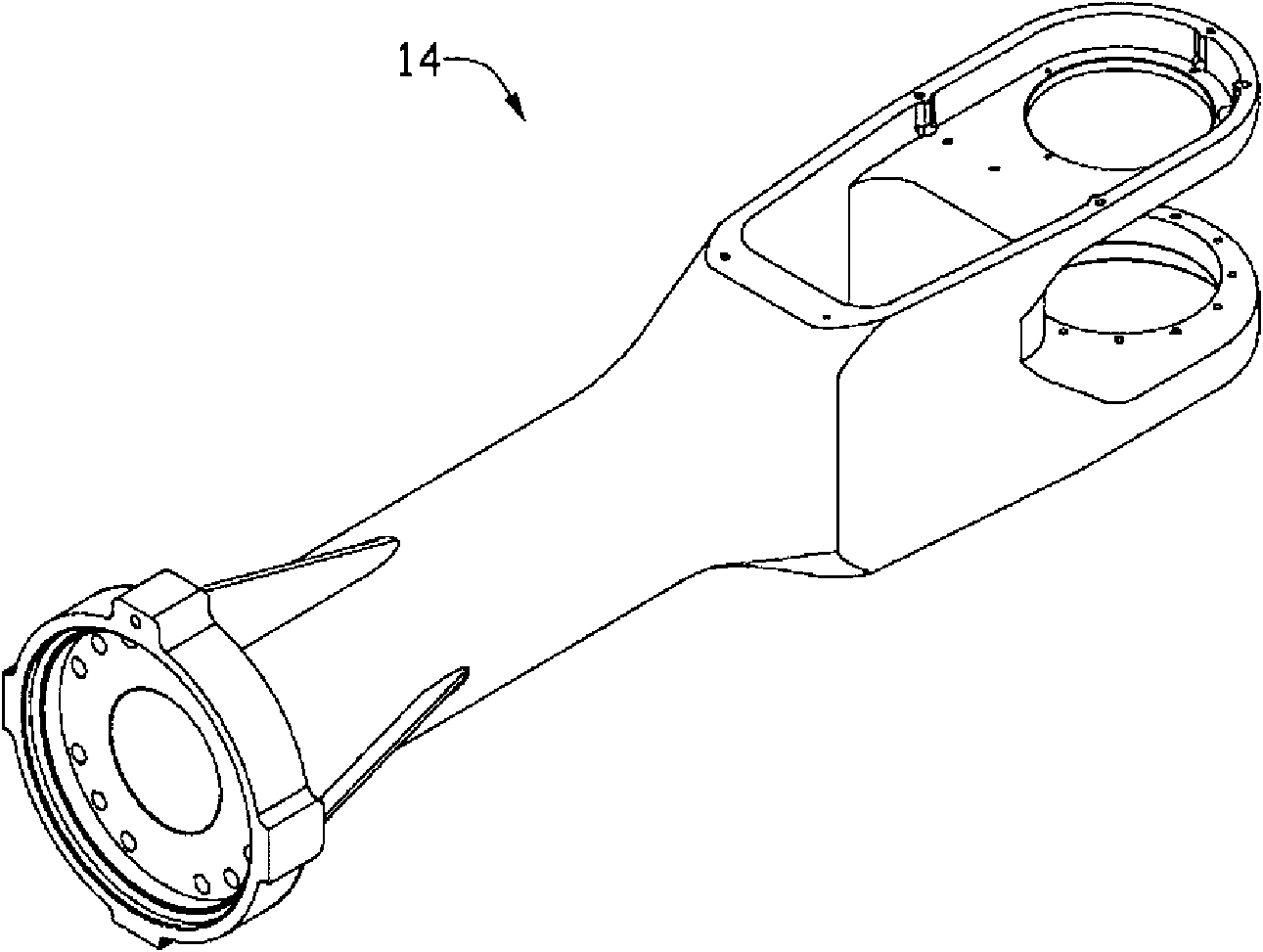

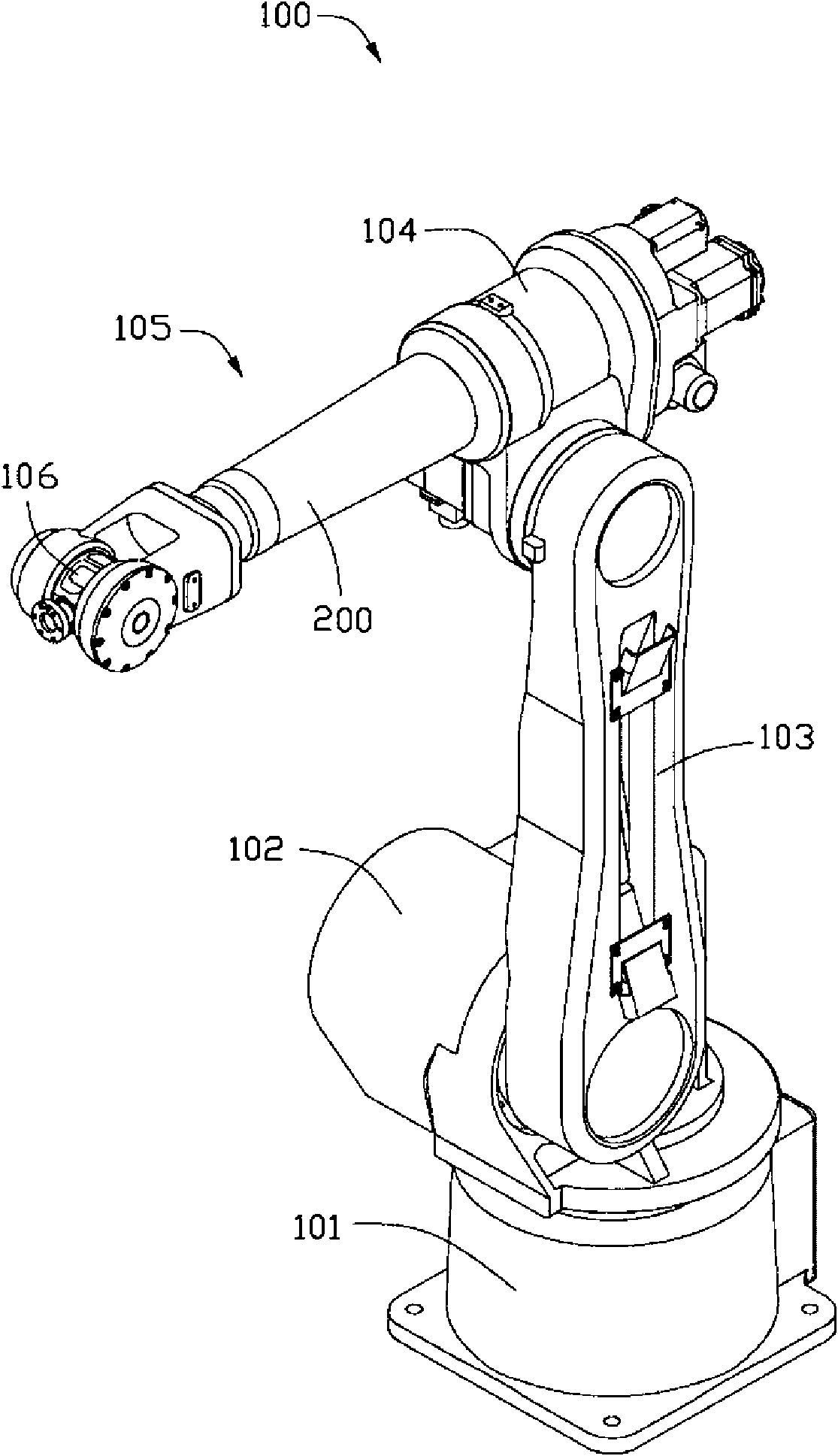

[0019] see image 3 , the robot 100 of Embodiment 1 of the present invention is similar to the robot described in the background art (see figure 1 ), which includes a base 101, a frame 102 that is rotatably arranged on the base 101, a boom 103 that is rotatably arranged on the frame 102, a connecting arm 104 that is rotatably connected with the boom 13, and a connecting arm 104 that is rotatably connected Rotate the attached arm 105 . The small arm 105 includes an arm component 200 , a driving component (not shown) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com