Enclosing wall stand column construction method

A construction method and column technology, which can be applied to fences, building types, buildings, etc., can solve problems such as edge dislocation in the up and down directions of the column, environmental impact, and poor environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in combination with specific embodiments.

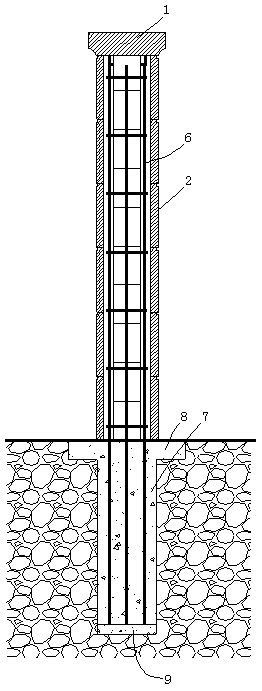

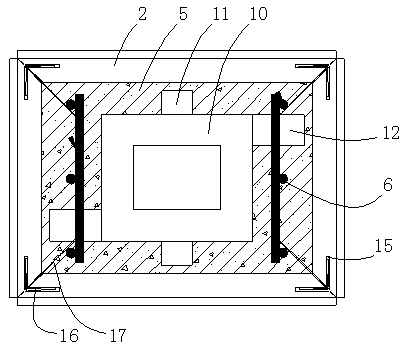

[0050] During specific implementation: a construction method for a wall column, comprising the following steps: a. Excavating a foundation pit, digging the foundation pit downwards along the designed position of the column at a depth of more than 800cm downwards, and extending the excavation around the ground at the upper end of the foundation pit A settling tank, a layer of crushed stone cushion is set at the bottom of the foundation pit; b. After the foundation pit is dug, the foundation is poured. During pouring, two vertical rows of steel bars are pre-embedded in the foundation. The upper end of the vertical steel bars is exposed to the foundation and serves as the foundation of the steel grid frame inside the column. The foundation forms an anti-settling expansion part at the sinker position, and the upper end of the foundation is leveled; c. Reinforced grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com