Pipe shape control method for rolling seamless steel pipe by using seven-frame tandem mill

A technology of seamless steel pipe and control method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., and can solve the problems affecting the control accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Basic geometric parameters of seamless steel pipes:

[0106] Tube outer diameter: D = 244.5mm; tube outer diameter allowable deviation: (-1.0% ~ +1.0%) D;

[0107] Tube wall thickness: t=15.11mm; tube wall thickness tolerance: (-12.0%~+12.0%)t;

[0108] Casing ovality: ovality ≤ 1.0% D;

[0109] The bending degree of the pipe body is not greater than 0.50% of the total length of the steel pipe; the bending degree of the pipe end is not greater than 1.5mm / m.

[0110] Billet size:

[0111] According to the final product specification Φ244.5mm×13.84mm, the designed billet size is: Φ310mm.

[0112] The roll is made of cast steel, and the material properties are shown in Table 1.

[0113] Table 1 Material properties

[0114]

[0115] The temperature of the rolling process was 1100°C.

[0116] The speed of the first roll is 1.59956m / s, the initial speed of the waste pipe is 1.5m / s, and the speed of the seventh roll is 3.28474m / s.

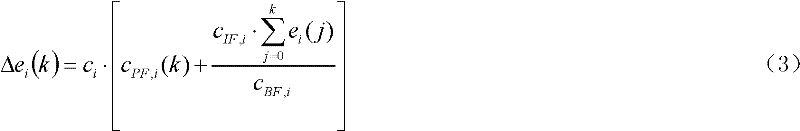

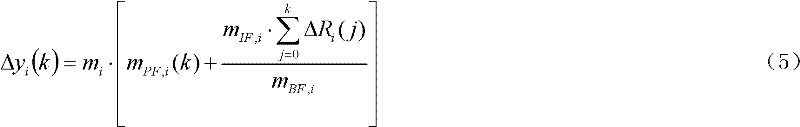

[0117]In the seven-stand continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com