Preparation method of composite material thruster stator

A technology of composite materials and thrusters, which is applied to household components, household appliances, and other household appliances, can solve the problems of high processing costs, serious cavitation erosion, poor acoustic damping, etc., and achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] According to a preferred embodiment of the present invention, the method for preparing a composite propeller stator includes the steps of:

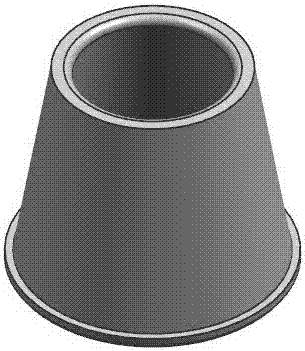

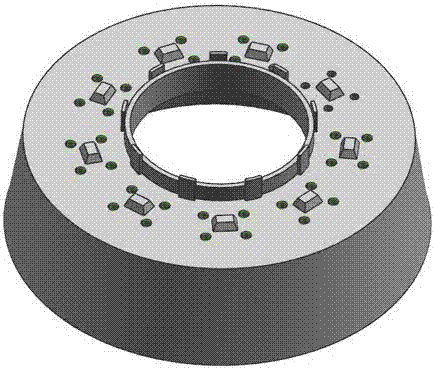

[0023] (1) The outer part of the stator hub is formed: use figure 1 The molding mold for the outer layer of the hub shown in the figure, clean the mold and wipe off the release wax, and then lay a certain thickness of fiber cloth on the mold to prepare the outer layer of the hub; after the outer layer of the hub is fully cured, connect it to the blade Open the groove according to the shape of the blade root.

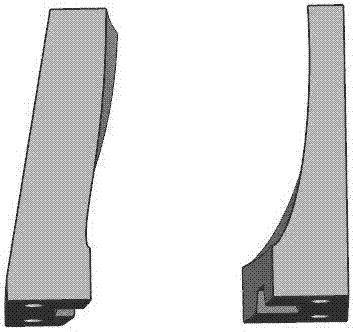

[0024] (2) Manufacture of stator blades in pieces: process stator blade molds, select reinforcement materials and design layups; use prepreg mixed with fiber cloth, from the root and tip of the blade mixed with fiber cloth The multi-layer transition fibers of a certain size are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com