Ship transformable propeller based on bidirectional shape memory polymer composite propeller blades

A memory polymer and composite material technology, applied in the direction of rotating propellers, rotary propellers, ships, etc., can solve the problem that the navigation of the ship cannot be changed, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

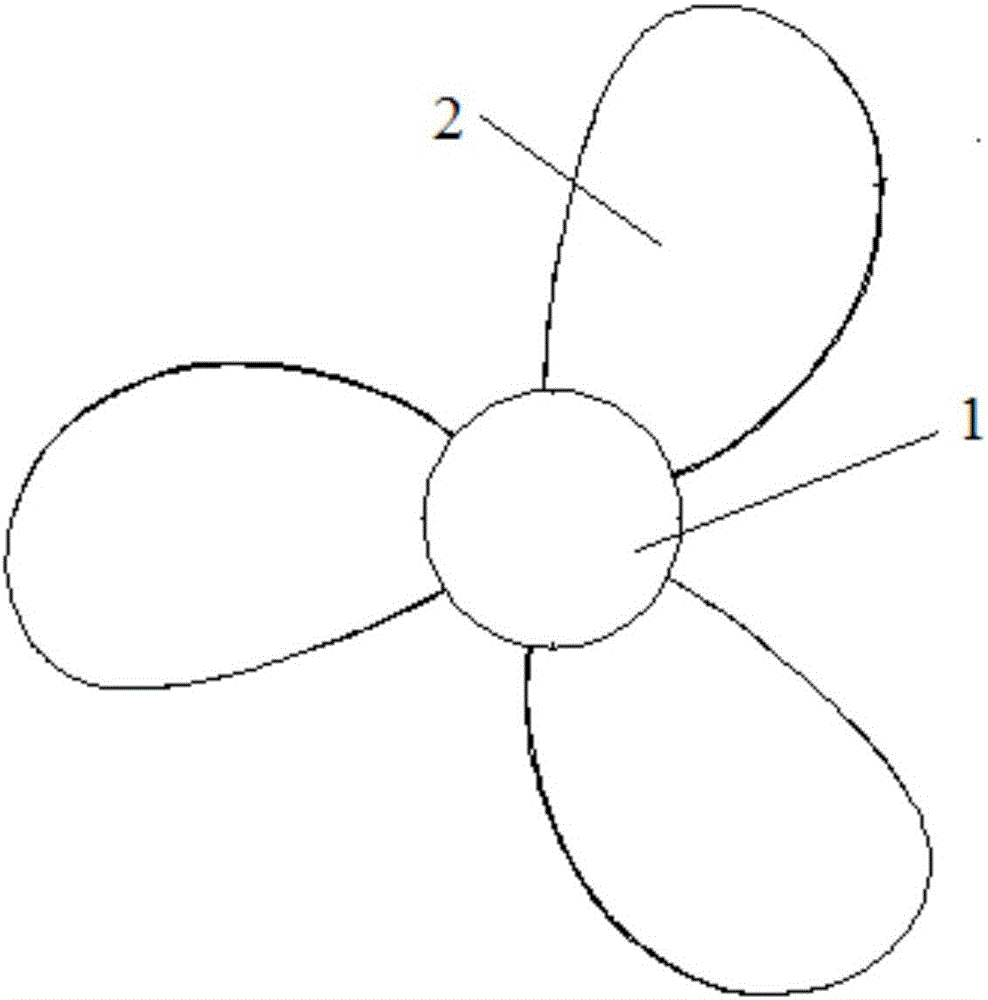

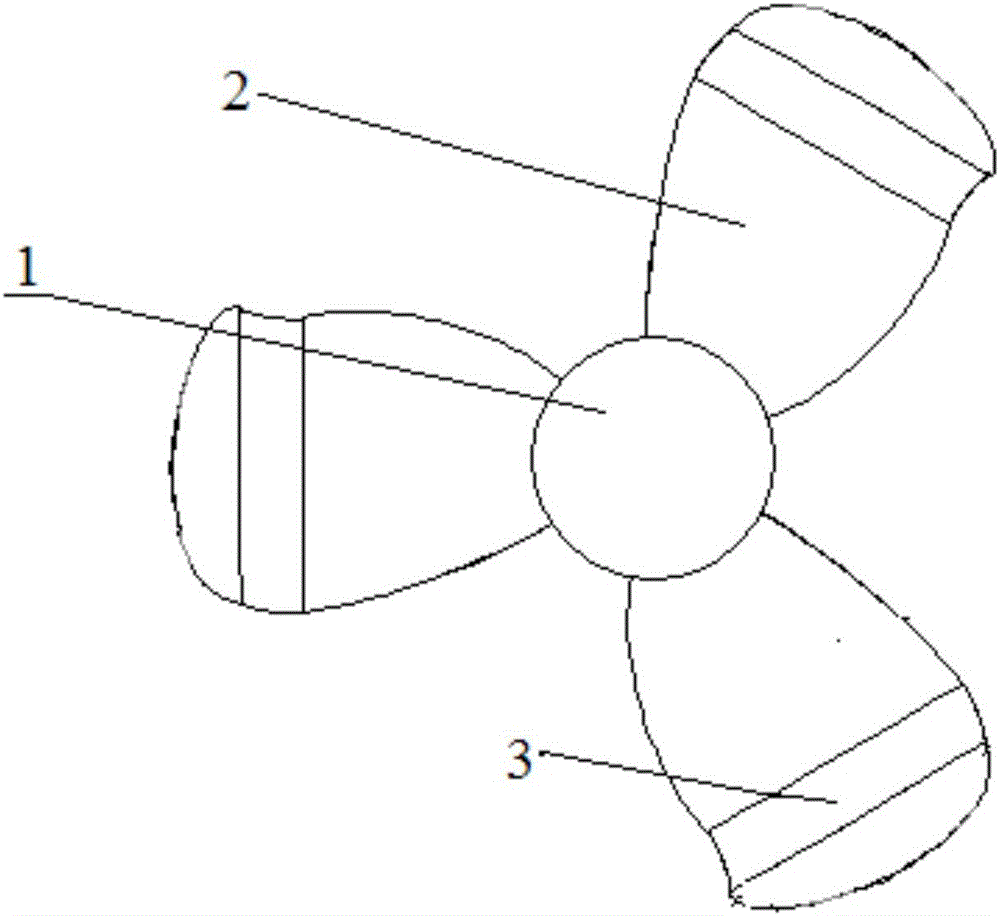

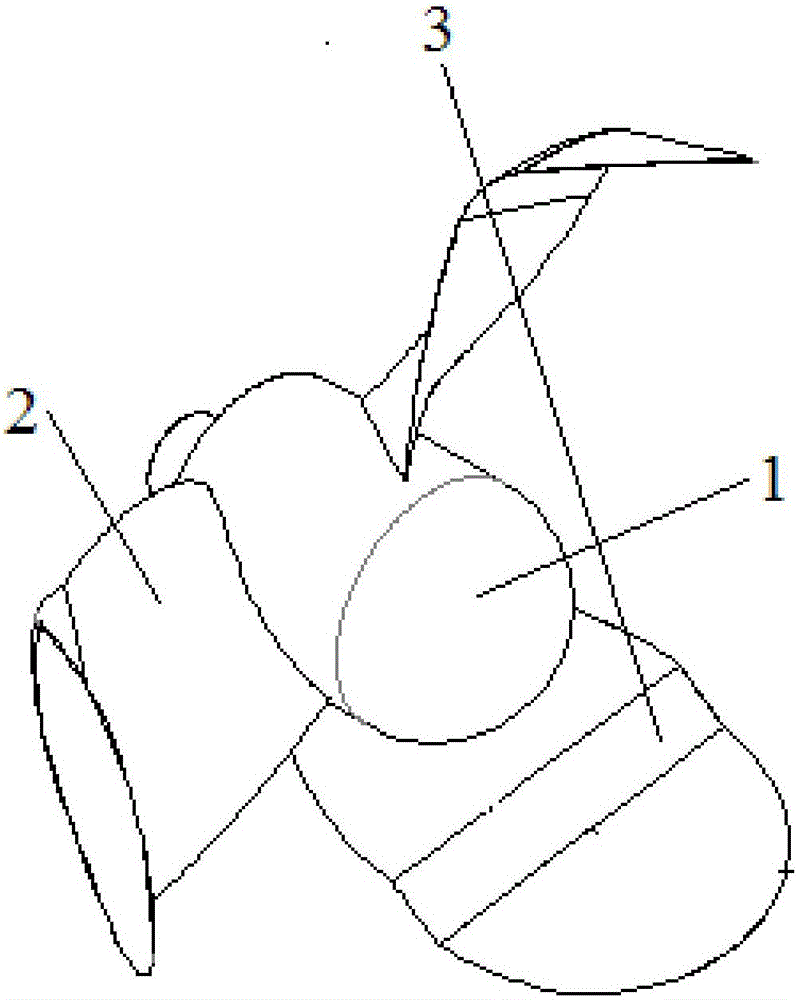

[0016] Specific implementation mode one: combine Figure 1-3 , this embodiment is a deformable propeller for ships based on two-way shape memory polymer composite blades, which is specifically composed of a hub 1 and a plurality of blades 2; the plurality of blades 2 are evenly arranged and fixed on a On the propeller hub 1; the propeller hub 1 is made of nickel, aluminum, bronze, titanium alloy material or resin matrix and fiber reinforced phase, wherein the mass fraction of the fiber reinforced phase is 30% ~70%; the paddle 2 is made of a material composed of two-way shape memory polymer and fiber reinforcement phase, wherein the mass fraction of fiber reinforcement phase is 30%-70%.

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the propeller hub 1 is made of nickel, aluminum, bronze, titanium alloy material or composite material of resin matrix and fiber reinforcement , where the fiber reinforcement is carbon fiber, glass fiber, Kevlar fiber or boron fiber. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the paddle 2 is made of a composite material of two-way shape memory polymer and fiber reinforcement, and the fiber reinforcement The phase is carbon fiber, glass fiber, Kevlar fiber or boron fiber. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com