Rotary heating type composite propeller curing oven

A composite material and rotary heating technology, used in household components, household appliances, other household appliances, etc., can solve the problems of temperature difference, large temperature difference, affecting the quality of composite propellers, etc., to achieve uniform temperature in the furnace and heat utilization rate. Tall, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

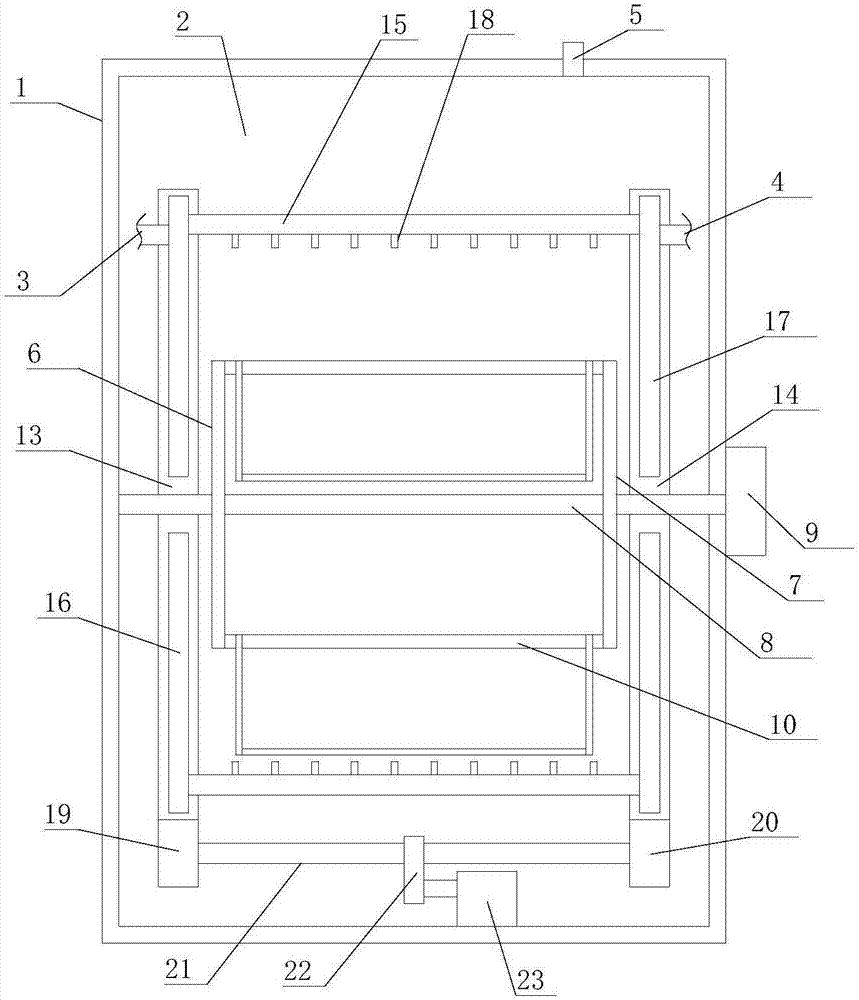

[0022] refer to Figure 1-Figure 4 , the present invention proposes a rotary heating type composite material propeller curing furnace, including a furnace body 1, a heating mechanism, a mold placement mechanism, a timer and a controller, wherein:

[0023] There is a curing chamber 2 inside the furnace body 1, and a circulating hot air outlet pipe 5 communicating with the curing chamber 2 is arranged on the furnace body 1, and a third valve is arranged in the circulating hot air outlet pipe 5.

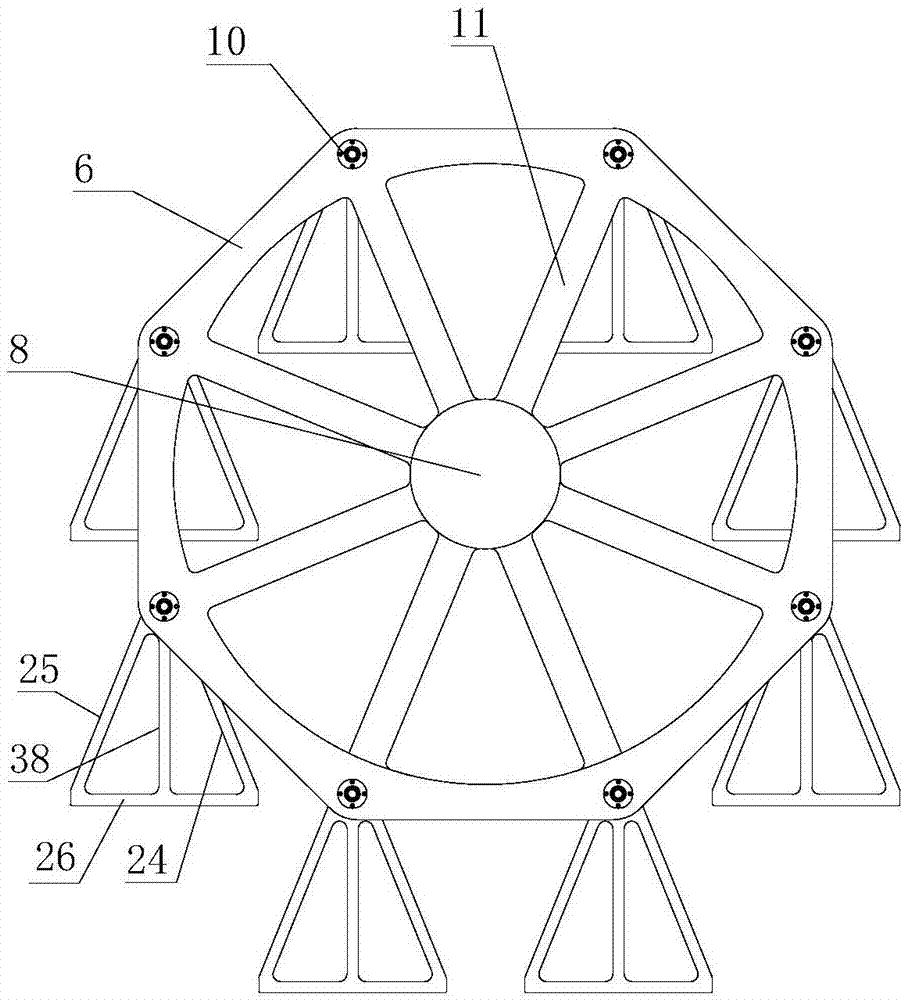

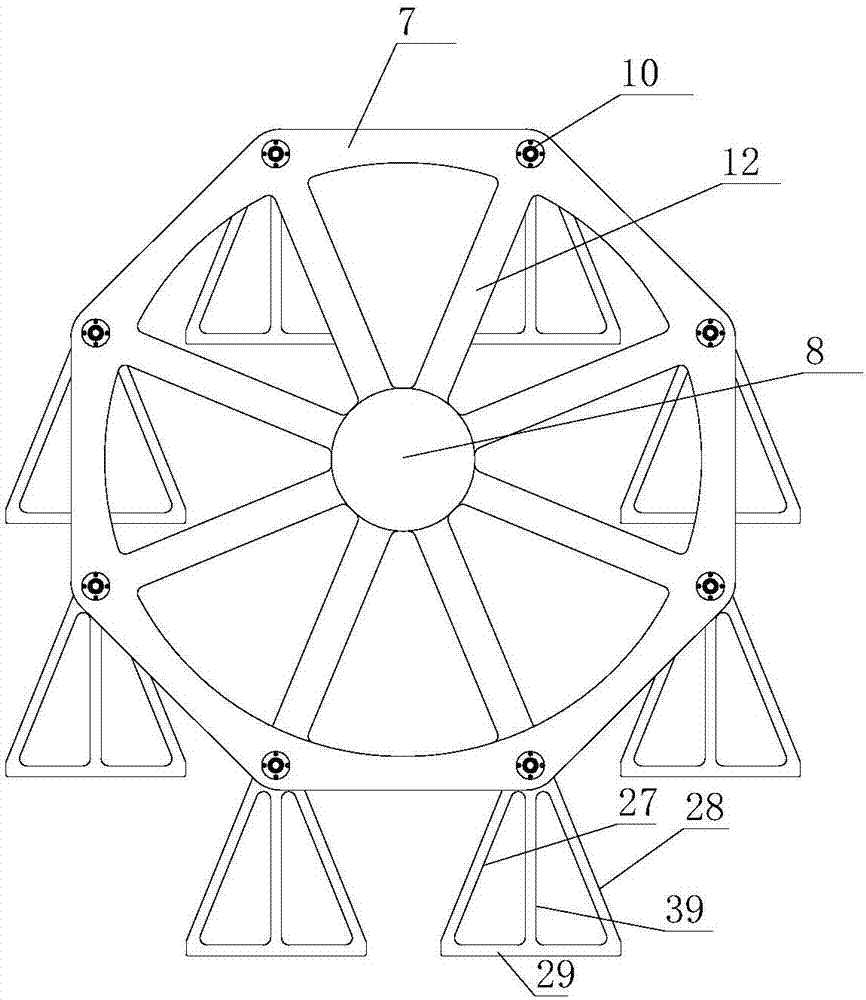

[0024] The mold placing mechanism includes a first mounting ring 6, a second mounting ring 7, a rotating shaft 8, a first driving mechanism 9, a plurality of supporting shafts 10 and a plurality of mold placing frames. The first mounting ring 6 and the second mounting ring 7 are relatively arranged in the curing chamber 2, the first end of the rotating shaft 8 is rotatably connected with the first side wall of the furnace body 1, and the second end of the rotating shaft 8 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com