Rotor composite propeller of helicopter

A technology of rotor helicopters and propellers, applied in the field of aircraft, can solve the problems of inability to stall and glide, poor maneuverability, long take-off distance, etc., and achieve the effects of improving flight reliability, reducing overall weight and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

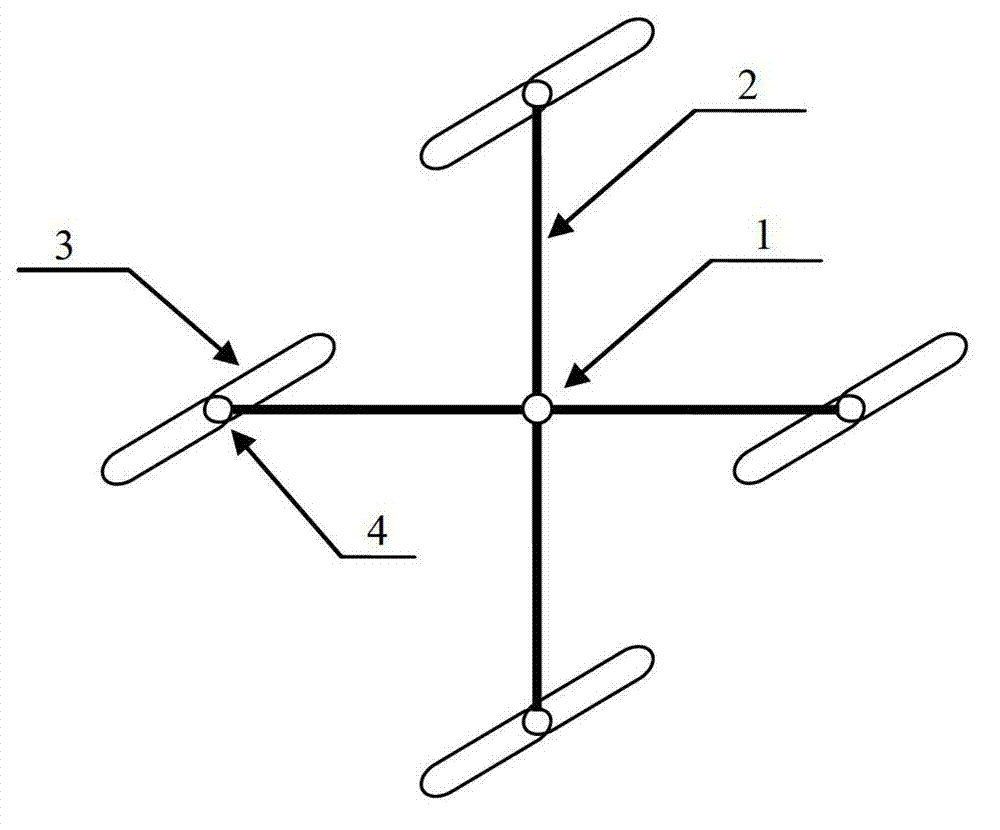

[0020] Such as figure 1 As shown, the composite rotor helicopter propeller includes a main propeller shaft 1, 4 main propeller arms 2, rotor blades 3 and a rotor shaft 4; the main propeller shaft 1 is connected with the helicopter power shaft to provide power for the entire propeller; the 4 main propellers The arms 2 are distributed symmetrically in space. One end of the main propeller arm 2 is fixed on the main propeller shaft 1 , and the other end is installed with a rotor shaft 4 ; the rotor blades 3 are fixed on the rotor shaft 4 .

[0021] When the main propeller shaft 1 with power drives the main propeller arm 2 to rotate, the rotor blades 3 at the ends of the four main propeller arms 2 are driven to rotate by air resistance, and the rotor shaft 4 is an unpowered shaft, so that the rotation plane of the rotor blade 3 is in line with the main propeller The advancing direction of the arm 2 is at a certain elevation angle to generate lift.

[0022] The aircraft is similar ...

Embodiment 2

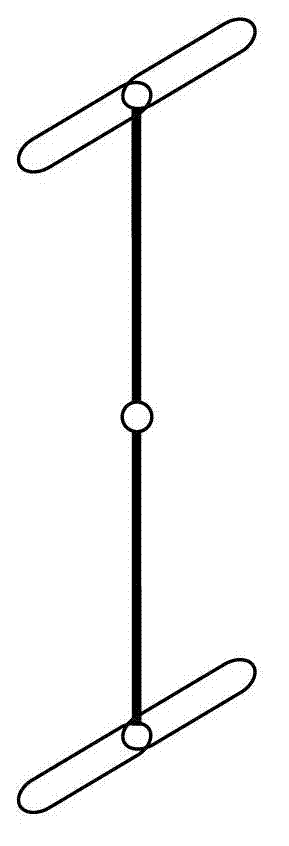

[0025] Such as figure 2 As shown, the composite rotor helicopter propeller includes a main propeller shaft 1, two main propeller arms 2, rotor blades 3 and a rotor shaft 4. The two main propeller arms 2 are symmetrically distributed in space, and the others are the same as in Embodiment 1.

Embodiment 3

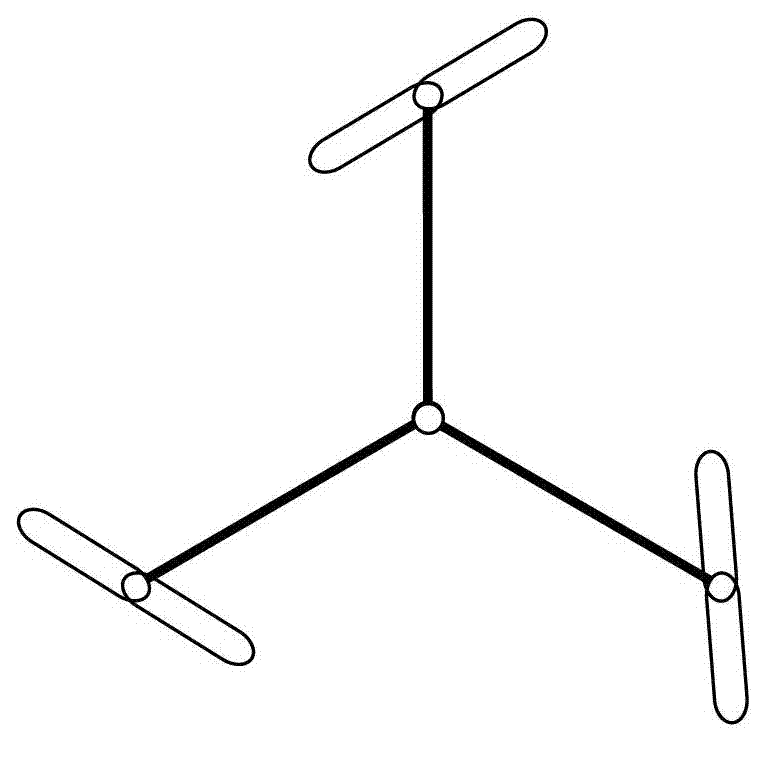

[0027] Such as image 3 As shown, the composite rotor helicopter propeller includes a main propeller shaft 1, three main propeller arms 2, rotor blades 3 and a rotor shaft 4. The three main propeller arms 2 are symmetrically distributed in space, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com