Composite propeller blade structure

a propeller blade and composite technology, applied in the direction of wind motors, wind motors with perpendicular air flow, motors, etc., can solve the problems of inability to carry out further performance boosting, and achieve the effect of effective boosting the performance of the propeller blade, reasonable production cost, and better energy consumption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Preferred embodiments of the present invention will be described with reference to the drawings.

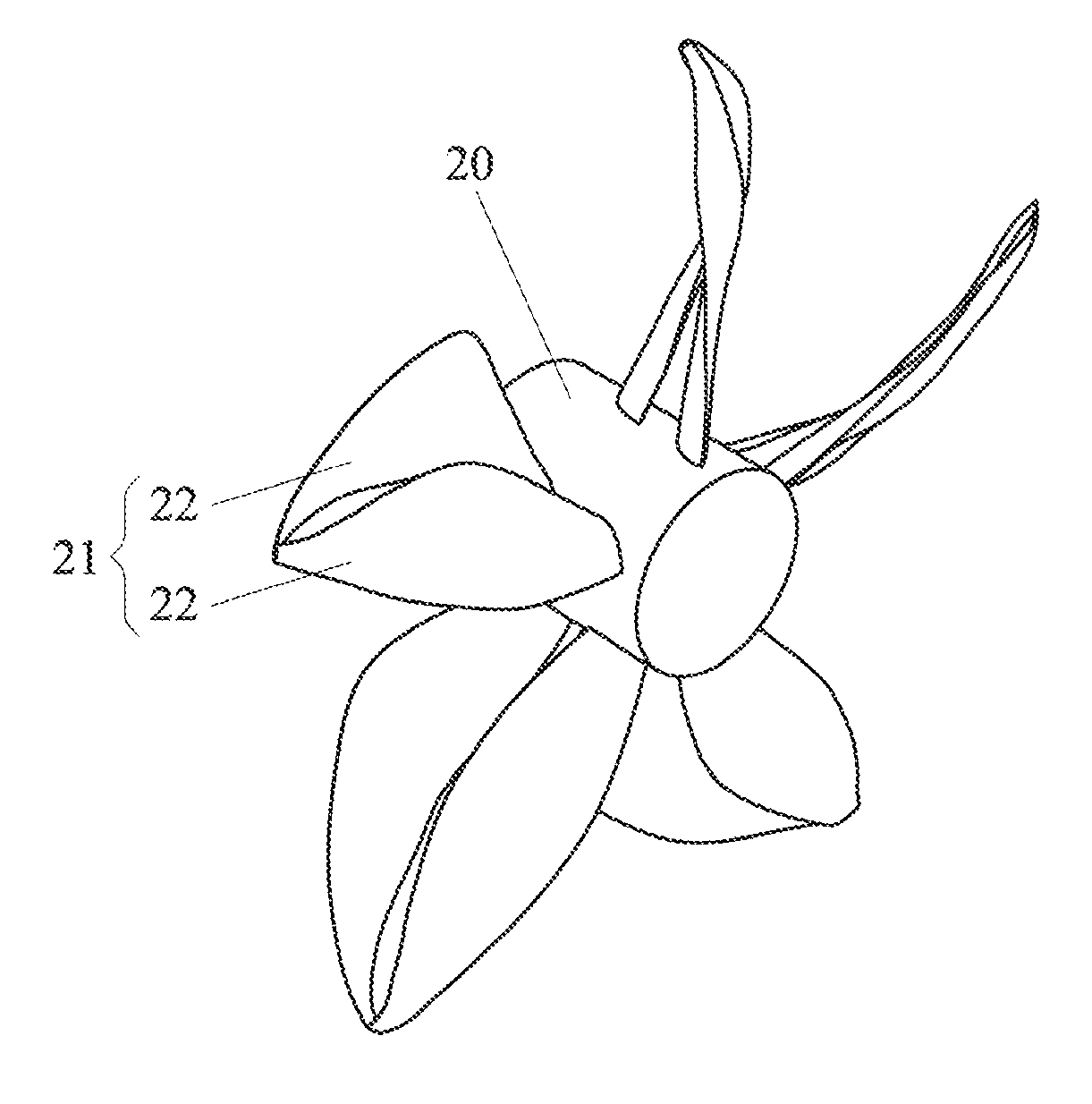

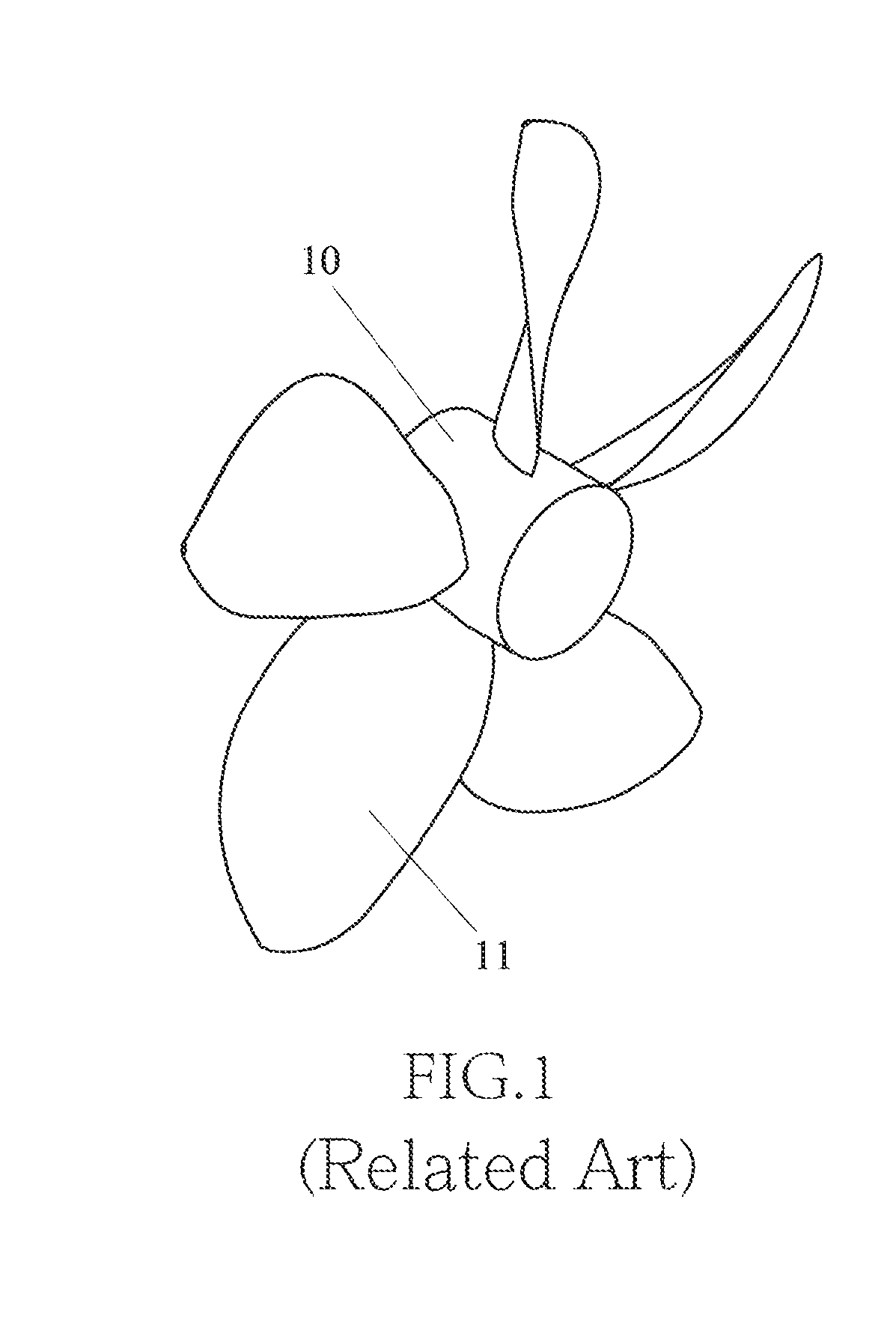

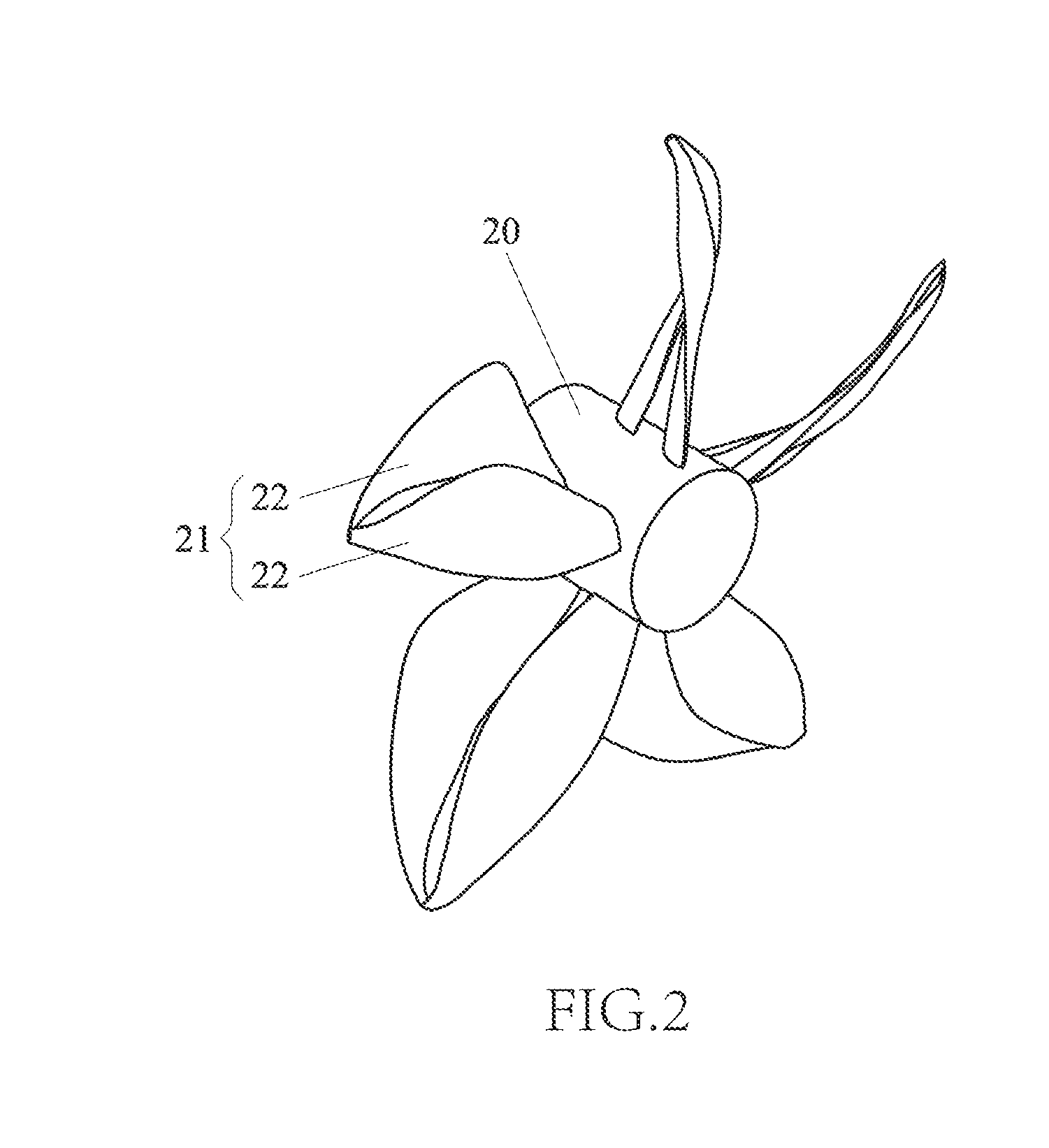

[0020]The present invention discloses a composite propeller blade structure including at least a rotation shaft and a rotation surface correspondingly formed relative to the rotation shaft, and plural blades are formed on the rotation surface, which is characterized in that: each of the blades is composed of plural blade units, wherein the distance between any two adjacent blades is greater than the distance between any two adjacent blade units, and the suction side of the blade unit at the downstream is located in the position closer to the pressure side of the blade unit at the upstream rather than the suction side of the blade unit at the upstream. Accordingly, in the equivalent radius cross section of each of the blades, the installed location of a front edge of the blade unit at the downstream is defined as following: in the rotation axial direction, which is located behind a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com